Desulfurization wastewater zero-discharge treatment device and method

A technology for desulfurization wastewater and treatment device, which is used in gaseous discharge wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of poor drying strength, high pressure on working parts, and irremovable particles, etc. Achieve excellent drying effect, improve cleanliness, and improve the evaporation rate of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

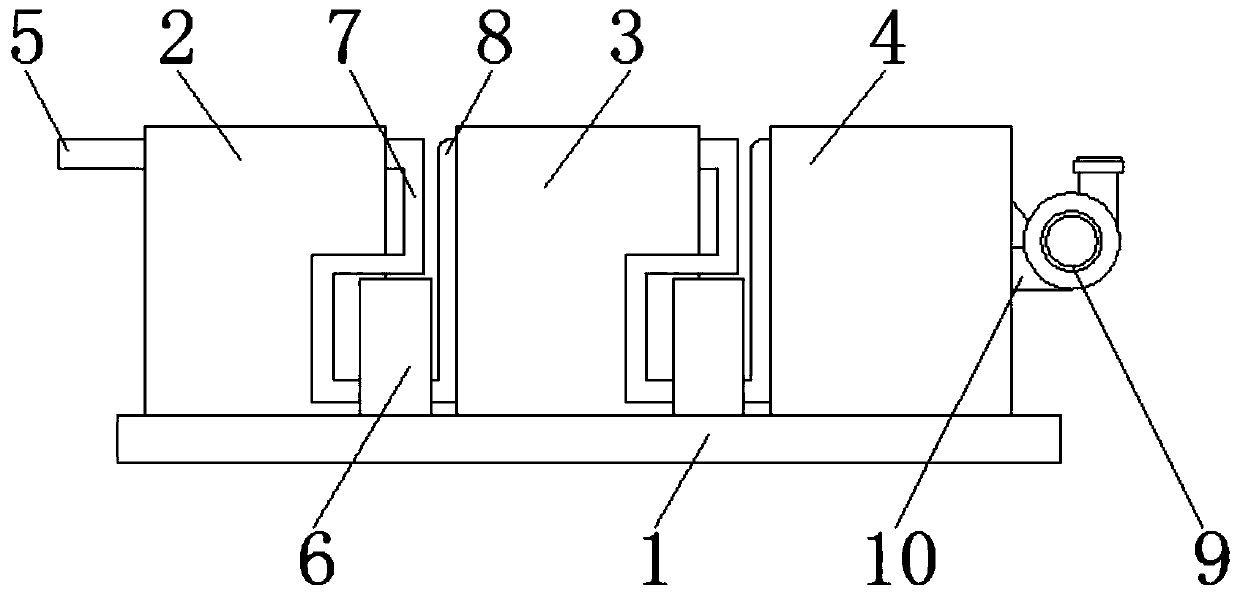

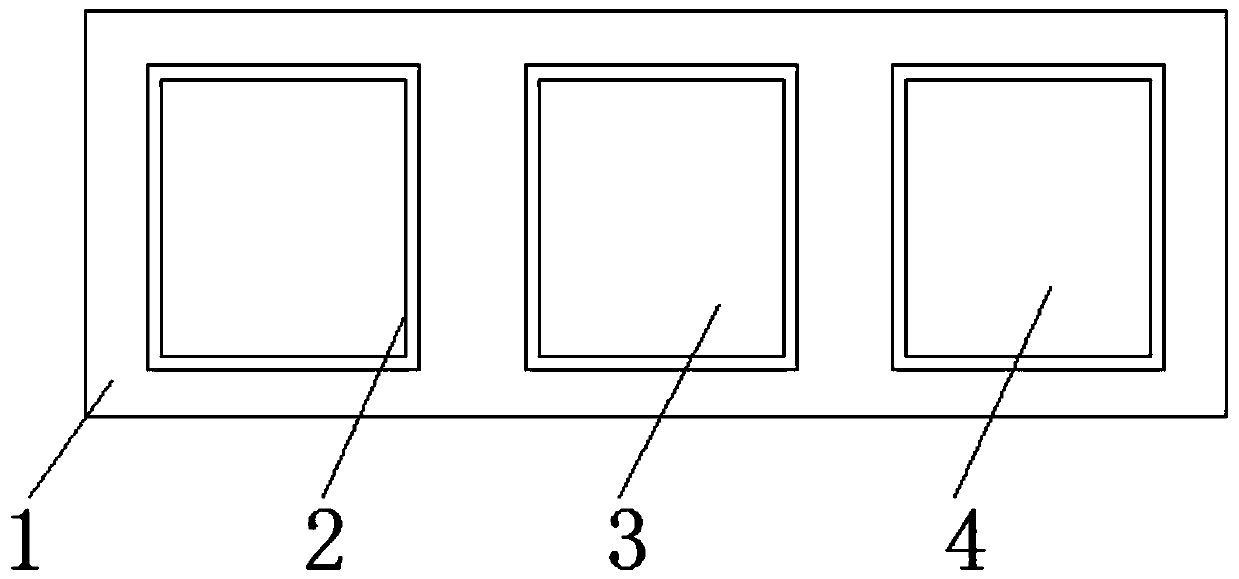

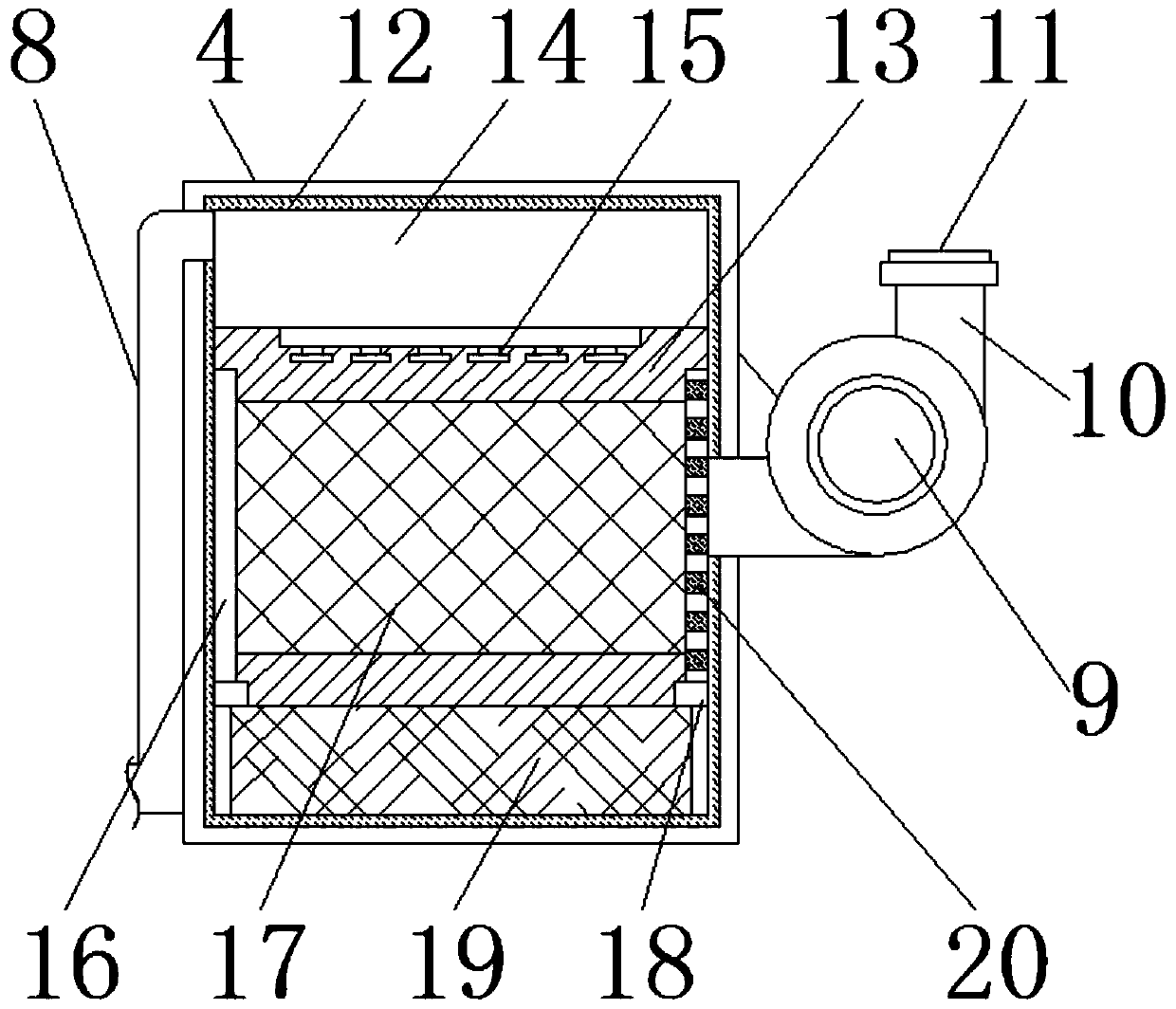

[0031] refer to Figure 1-3 , a zero-discharge treatment device for desulfurization wastewater, including a base 1, the upper surface of the base 1 is fixedly installed with a pre-sedimentation tank 2, a wastewater buffer tank 3 and a treatment tank 4 in sequence from left to right, and the upper surface of the base 1 There are two groups of water pumps 6 arranged horizontally, and the two groups of water pumps 6 are respectively arranged between the pre-sedimentation tank 2 and the wastewater buffer tank 3 and between the wastewater buffer tank 3 and the treatment tank 4. The middle position at the bottom of the side wall and the middle position at the top of the side wall of the waste water buffer tank 3 close to the treatment tank 4 are fixedly connected to the corresponding water pump 6 with a suction pipe 7, and the outer wall of the treatment tank 4 away from the waste water buffer tank 3 is fixedly installed There is a fan 9, and the top side and the bottom side of the ...

Embodiment 2

[0037] refer to figure 1 and Figure 3-4, a zero-discharge treatment device for desulfurization wastewater, including a base 1, the upper surface of the base 1 is fixedly installed with a pre-sedimentation tank 2, a wastewater buffer tank 3 and a treatment tank 4 in sequence from left to right, and the upper surface of the base 1 There are two groups of water pumps 6 arranged horizontally, and the two groups of water pumps 6 are respectively arranged between the pre-sedimentation tank 2 and the wastewater buffer tank 3 and between the wastewater buffer tank 3 and the treatment tank 4. The middle position at the bottom of the side wall and the middle position at the top of the side wall of the waste water buffer tank 3 close to the treatment tank 4 are fixedly connected to the corresponding water pump 6 with a suction pipe 7, and the outer wall of the treatment tank 4 away from the waste water buffer tank 3 is fixedly installed There is a fan 9, and the top side and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com