Heat exchangers for motor vehicles

A technology for heat exchangers and motor vehicles, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as unsatisfactory results, reduce production defects, reduce production costs, and avoid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

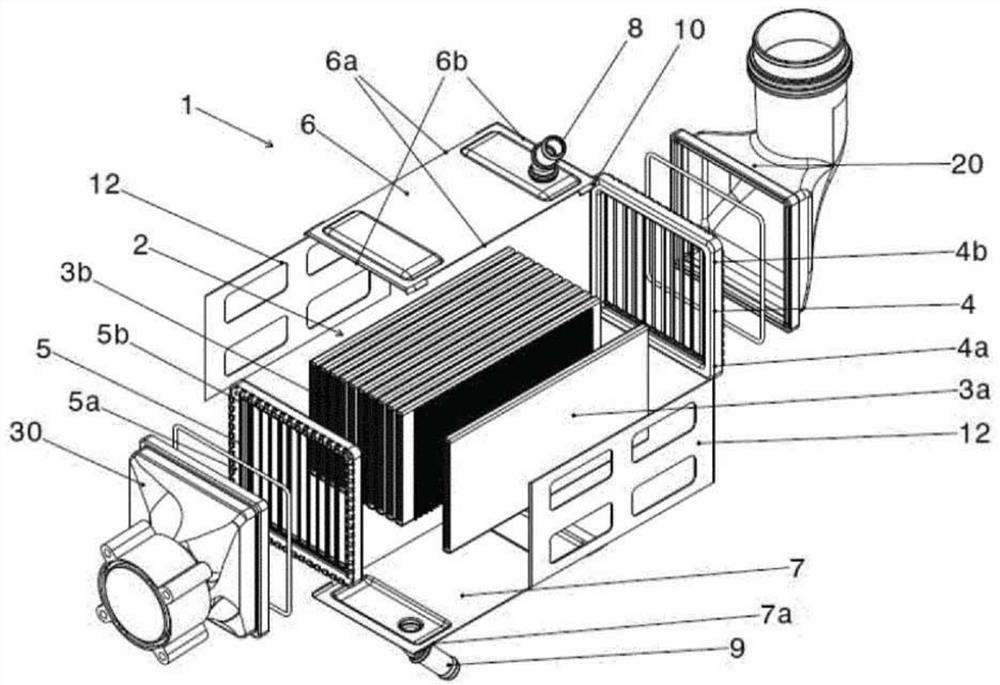

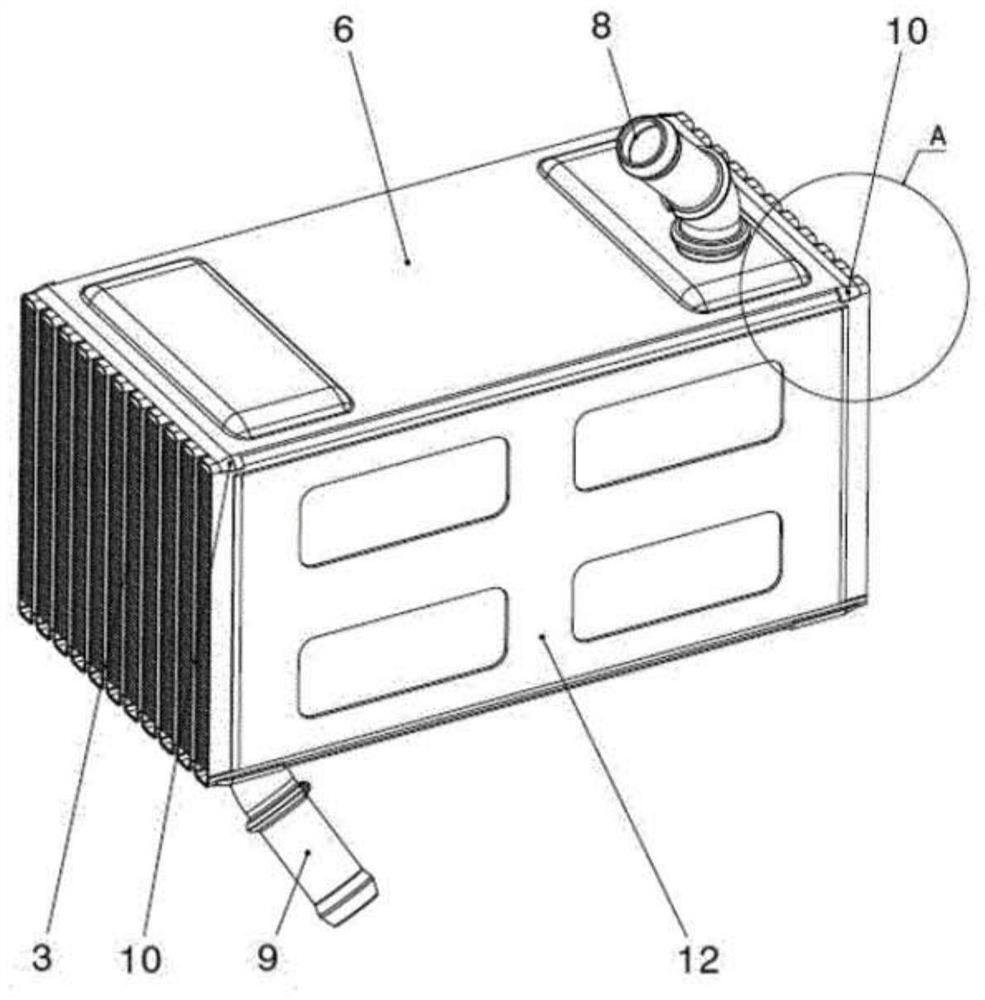

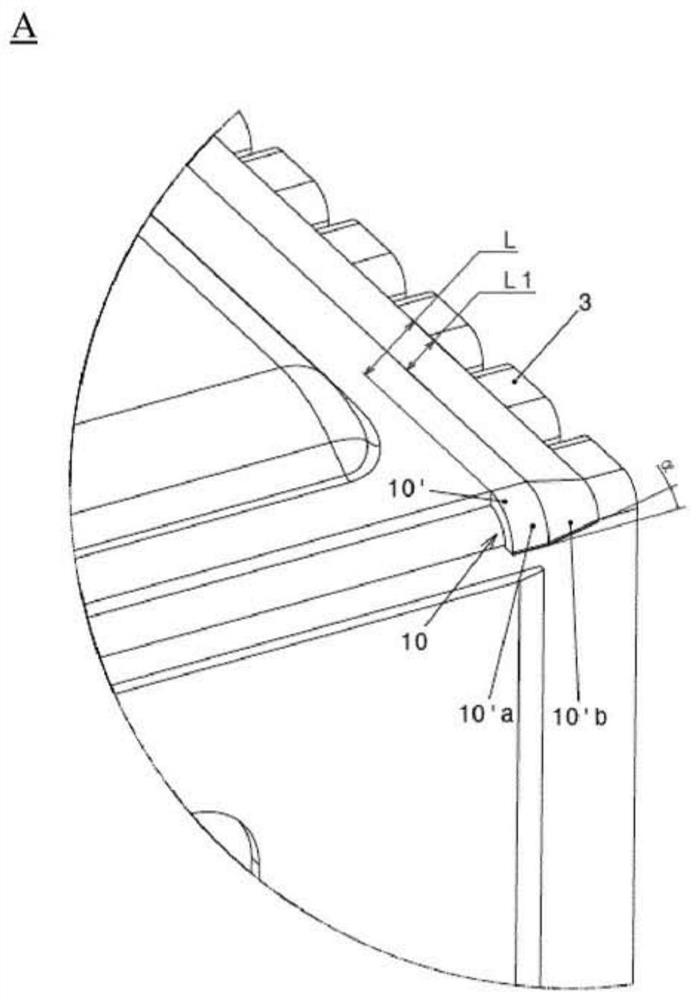

[0018] Such as figure 1 The shown heat exchanger 1 designed for a motor vehicle comprises a core 2 formed from a tube bundle with a plurality of flat tubes 3 for guiding the gas to be cooled in the heat exchanger 1 , in particular air. The flat tubes 3 have defined larger side surfaces and their smaller side surfaces, the larger side surfaces of which are arranged parallel to each other and at a distance from each other to form channels for guiding the cooling fluid therebetween. The tube bundle includes a first extreme tube 3a and a second extreme tube 3b located on both sides of the remaining tubes 3 of the tube bundle, respectively.

[0019] The tubes 3 , 3 a , 3 b of the core 2 are gas-tightly connected on one side of their open ends with an inlet header 4 through which cooling gas is delivered from the hot gas inlet channel 20 . The tubes 3 , 3 a , 3 b are airtightly connected at the other opposite side of their open ends to an outlet header 5 from which cooling gas is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com