Heat transfer coefficient detection heating device and heat transfer coefficient detection device

A heating device and heat transfer coefficient technology are applied in the fields of heat transfer coefficient detection heating devices and heat transfer coefficient detection devices, which can solve the problems of inconvenient detection, complicated structure of the heat transfer coefficient detection device, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

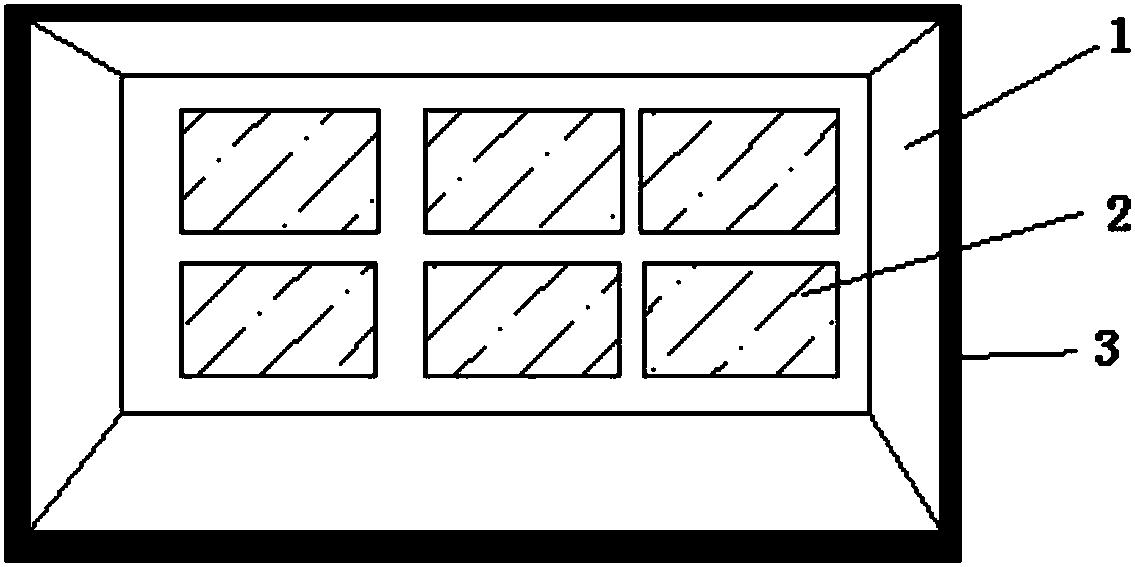

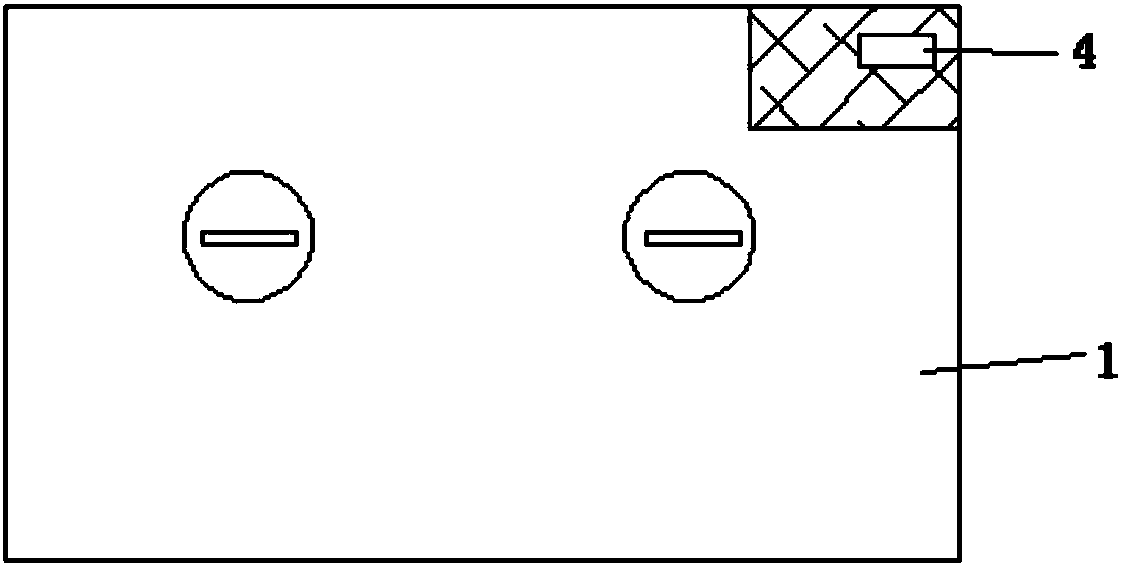

[0041] like Figure 1-3Shown is a specific implementation of a heat transfer coefficient detection heating device, including a box 1 with a length of 2 m, a height of 1 m, and a depth of 0.5 m. The box body 1 includes a box body with an outer layer and an inner layer and forms In the cavity inside the box body, the inner and outer layers of the box 1 are made of wear-resistant aluminum materials, and the outer layer and the inner layer of the box 1 are filled with heat insulating materials , the opening end of the box 1 is provided with a rubber sealing strip 3, and the film heater 2 as a heating device is arranged on the inner wall of the cavity, and the cavity is provided with a temperature collector for collecting the temperature in the box 1. The monitoring probe, the microcontroller is integrated on an inner wall of the cavity, the box body is provided with a card slot, the card slot is connected with the microcontroller, and the phone card is inserted into the card slot ...

Embodiment 2

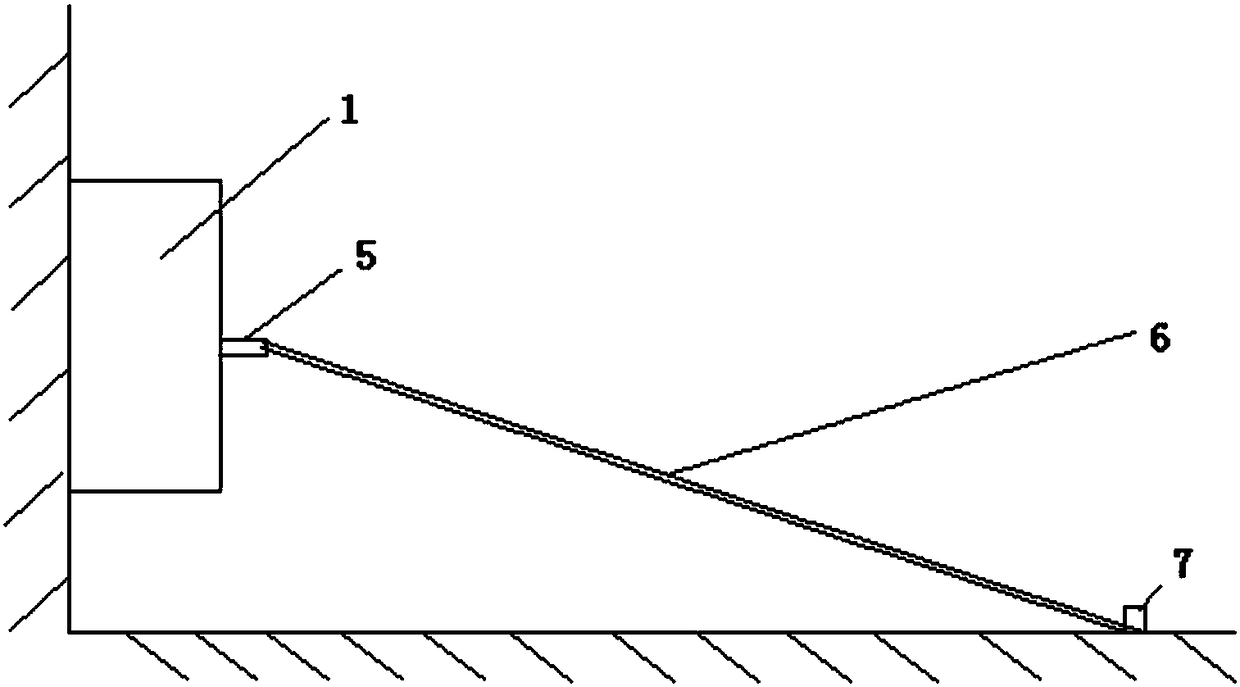

[0044] This embodiment is a specific implementation of a heat transfer coefficient detection device, including a heat transfer coefficient detection heating device provided in Embodiment 1, a heat flow meter plate, and a temperature testing instrument located on the outer surface of the enclosure.

[0045] During detection, after the calorimeter plate is attached to the inner surface of the maintenance structure in the box body 1 with adhesive tape, the box body 1 is fixed to the inner surface of the maintenance structure by the method in embodiment 1, and the box body 1 is heated to After the target temperature, record the temperature inside and outside the envelope, the temperature of the inner surface of the envelope, the temperature of the outer surface, and the value of the heat flow meter plate, calculate the heat transfer coefficient according to the heat transfer coefficient formula, and record multiple sets of data to calculate the average value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com