Subsea pipe flange pair connection installation device

A technology for marine pipe flange set and installation device, which is used in metal processing equipment, metal processing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

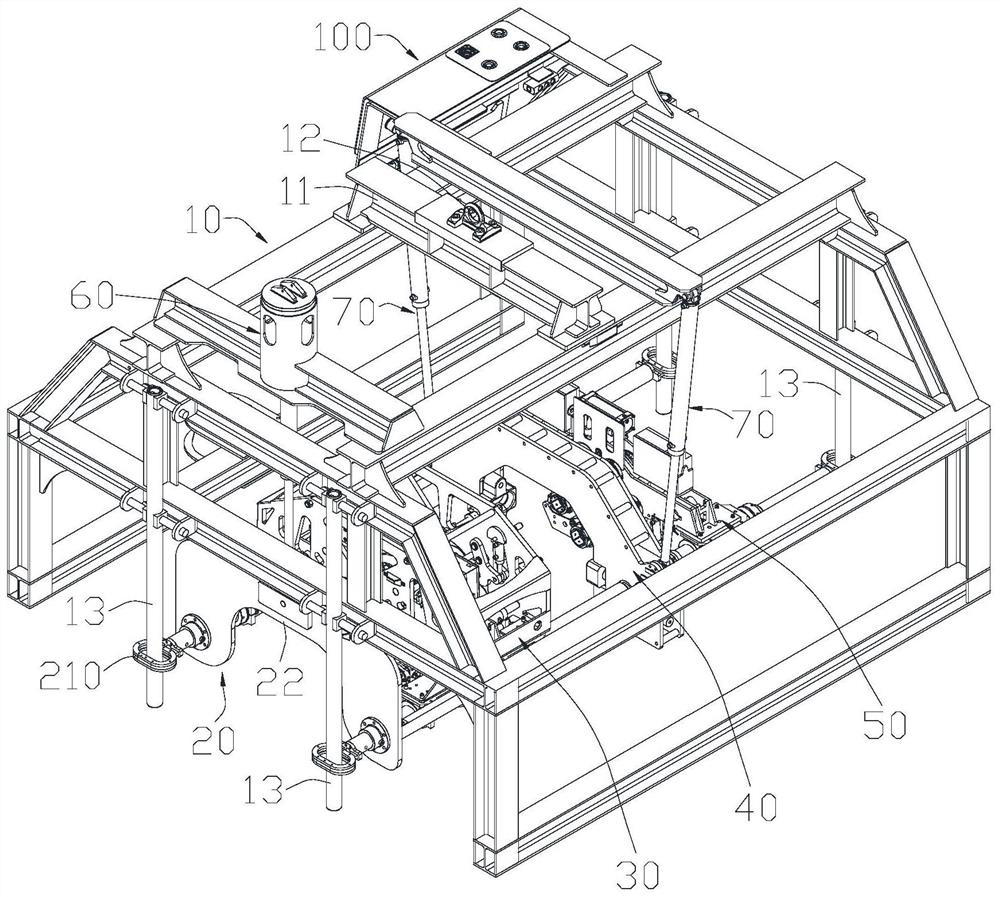

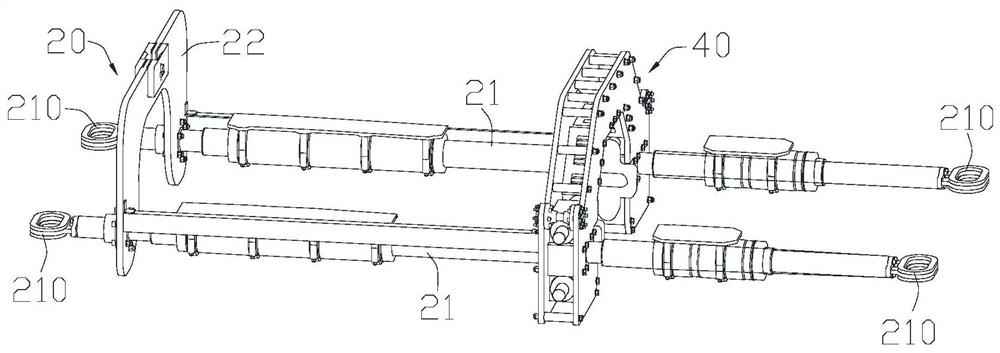

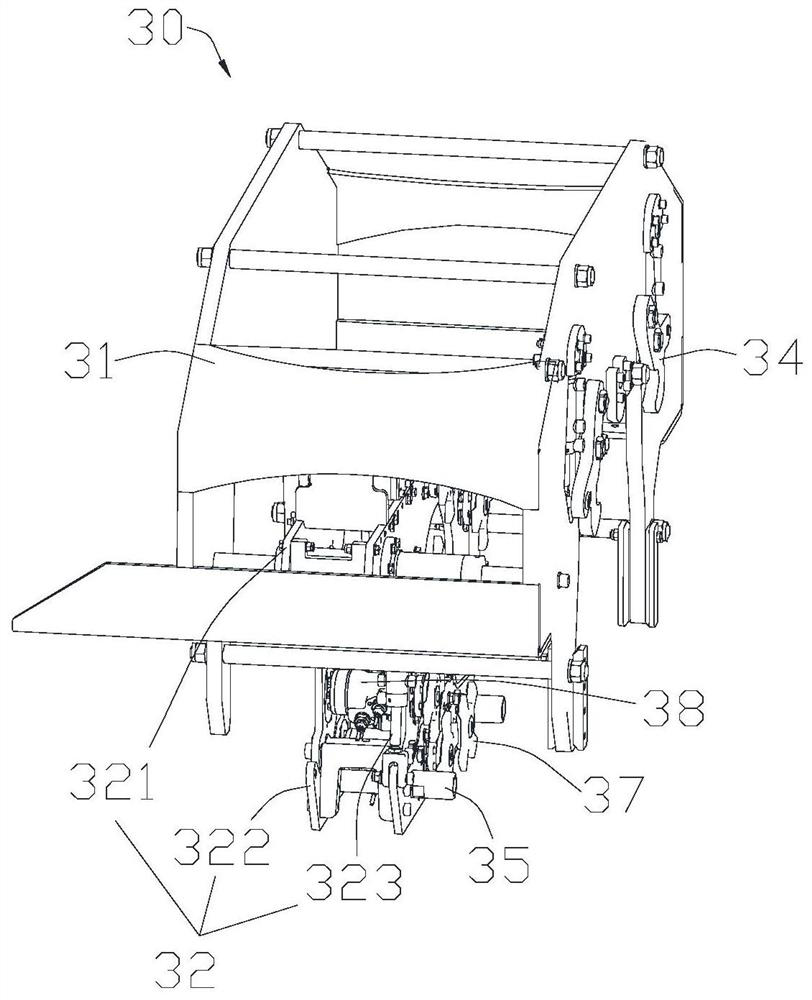

[0028] Such as figure 1 As shown, the sea pipe flange pair connection installation device according to an embodiment of the present invention includes a frame main body 10, a support rod assembly 20, and bolts for opening and closing clamping on sea pipes and inserting bolts into sea pipe flanges. Fixture 30, used for opening and closing clamping on the docked sea pipe flange to center the sea pipe flange 40, used for opening and closing clamping on the sea pipe and screwing in the nut Bolts are nut clamps 50 that fasten the flanges of the butt sea pipes.

[0029] The frame main body 10 is formed with channels running through its opposite ends, the support rod assembly 20, the bolt clamp 30, the flange clamp 40 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com