Floor slab for steel structure house

A steel structure and floor slab technology, applied to floors, structural elements, building components, etc., can solve the problems of heavy construction workload, single function, and high labor intensity of workers, so as to increase the contact surface area, improve the firmness, and improve the production efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

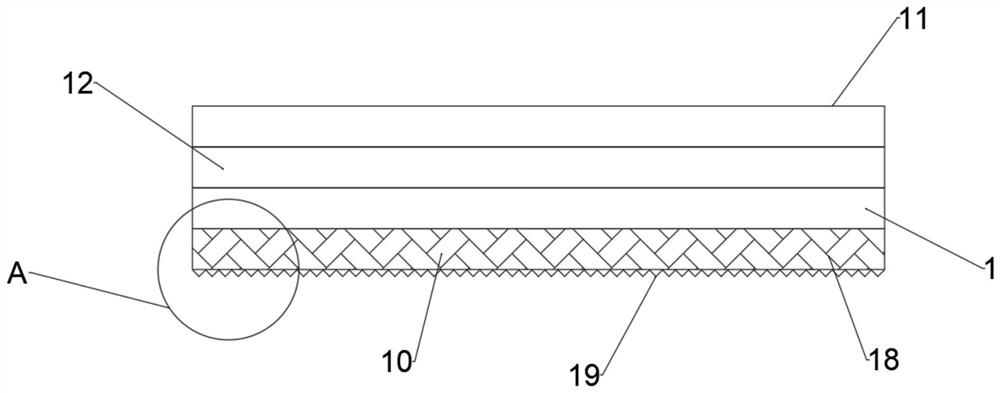

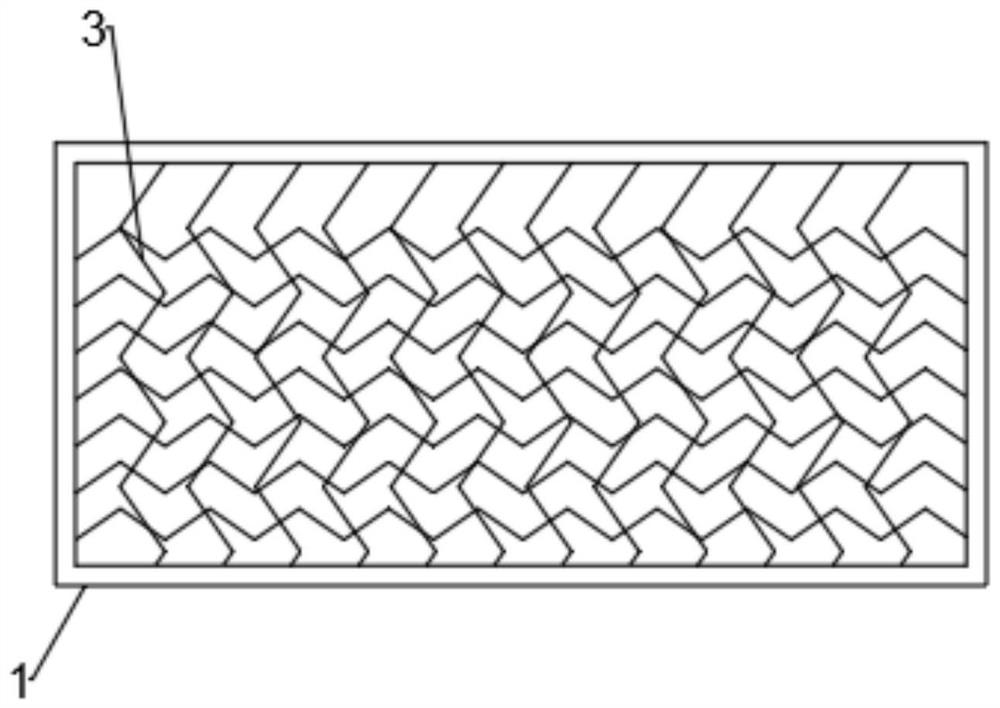

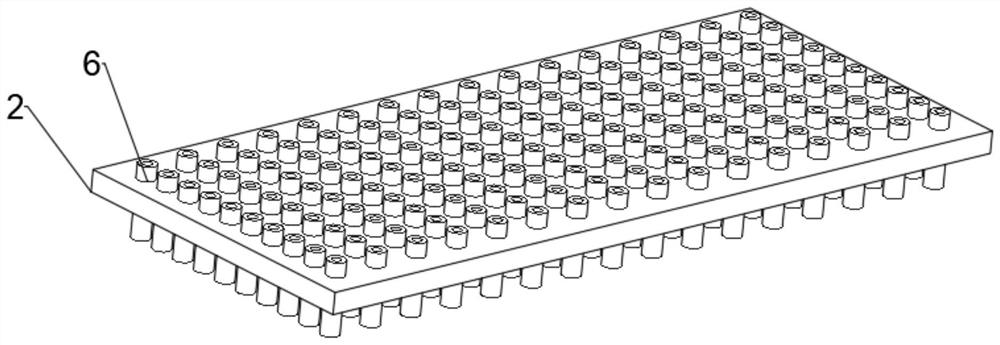

[0029] see Figure 1~6 , in an embodiment of the present invention, a steel structure residential floor, comprising a main floor 1, a thin plate 2, a sound insulation layer 10, a reinforced steel plate 11 and a thermal insulation layer 12, the top surface of the main floor 1 is provided with a groove 9, the groove 9 A plurality of steel bars 3 are arranged in a staggered fixed connection between the inner walls, the steel bars 3 are arranged in a folded line, concrete is poured in the groove 9, and the cover of the thin slab 2 is set on the top of the main floor 1 and is in contact with the concrete. A plurality of reinforcing columns 6 are arranged on the cloth, and the reinforcing columns 6 run through the concrete fixedly installed on the top surface of the thin plate 2 and extend to the groove 9 , and the first through holes 4 are opened in the reinforcing columns 6 .

[0030] Wherein, both ends of the thin plate 2 are symmetrically provided with V-shaped bumps 8, and both...

Embodiment 2

[0034] see Figure 7 , on the basis of Embodiment 1, the bottom surface of the thin plate 2 is equidistantly fixedly connected with a plurality of ribs 16 along its length direction, and the bottom surface of the main floor 1 is provided with a plurality of first card slots 14 and a plurality of second card slots. The slots 15, the first card slots 14 and the second card slots 15 are arranged vertically and alternately.

[0035] The working principle is: by setting the first card slot 14 and the second card slot 15 on the bottom surface of the main floor 1, it is convenient to carry and place the main floor 1 with a forklift, and at the same time, the amount of steel used is reduced to a certain extent. Production cost, through the bottom surface of the thin plate 2 is provided with a plurality of ribs 16, so that the thin plate 2 can fully contact with the concrete inside the groove 9, which improves the stability of the present invention.

Embodiment 3

[0037] see figure 1 and 4 , On the basis of Embodiments 1 and 2, the top surface of the thin plate 2 is fixedly installed with an insulating layer 12, and the top surface of the insulating layer 12 is connected with a reinforcing steel plate 11.

[0038] Wherein, one end of the reinforcement column 6 located above the thin plate 2 penetrates through the insulation layer 12 and extends to the inside of the reinforcement steel plate 11 to be fixedly connected with the reinforcement steel plate 11 .

[0039]Wherein, the bottom surface of the main floor 1 is fixedly connected with a sound-insulating layer 10, and the sound-insulating layer 10 is composed of a plurality of sound-absorbing sponge blocks 13 that are mutually inclined and staggered and fixedly connected with each other. Regular bumps 19.

[0040] The working principle is: after the main floor 1 and the thin plate 2 are made, the sound insulation layer 10 is set to make the present invention have a sound insulation e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com