Accurate in-place robot for building prefabricated part based on machine vision

A technology of prefabricated components and machine vision, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as low work efficiency, high labor intensity, and high risk, so as to reduce labor intensity, increase construction speed, and improve placement stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

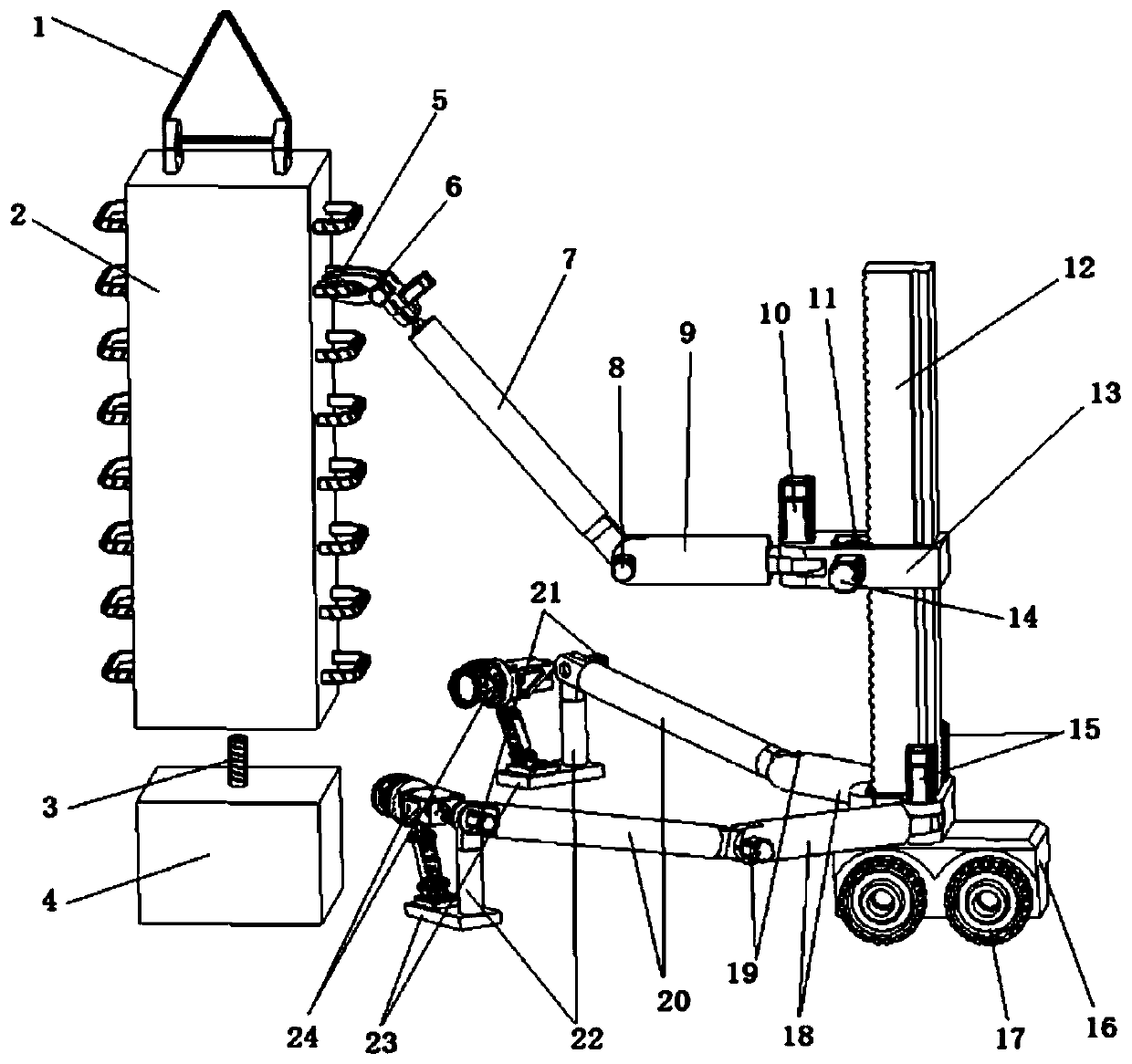

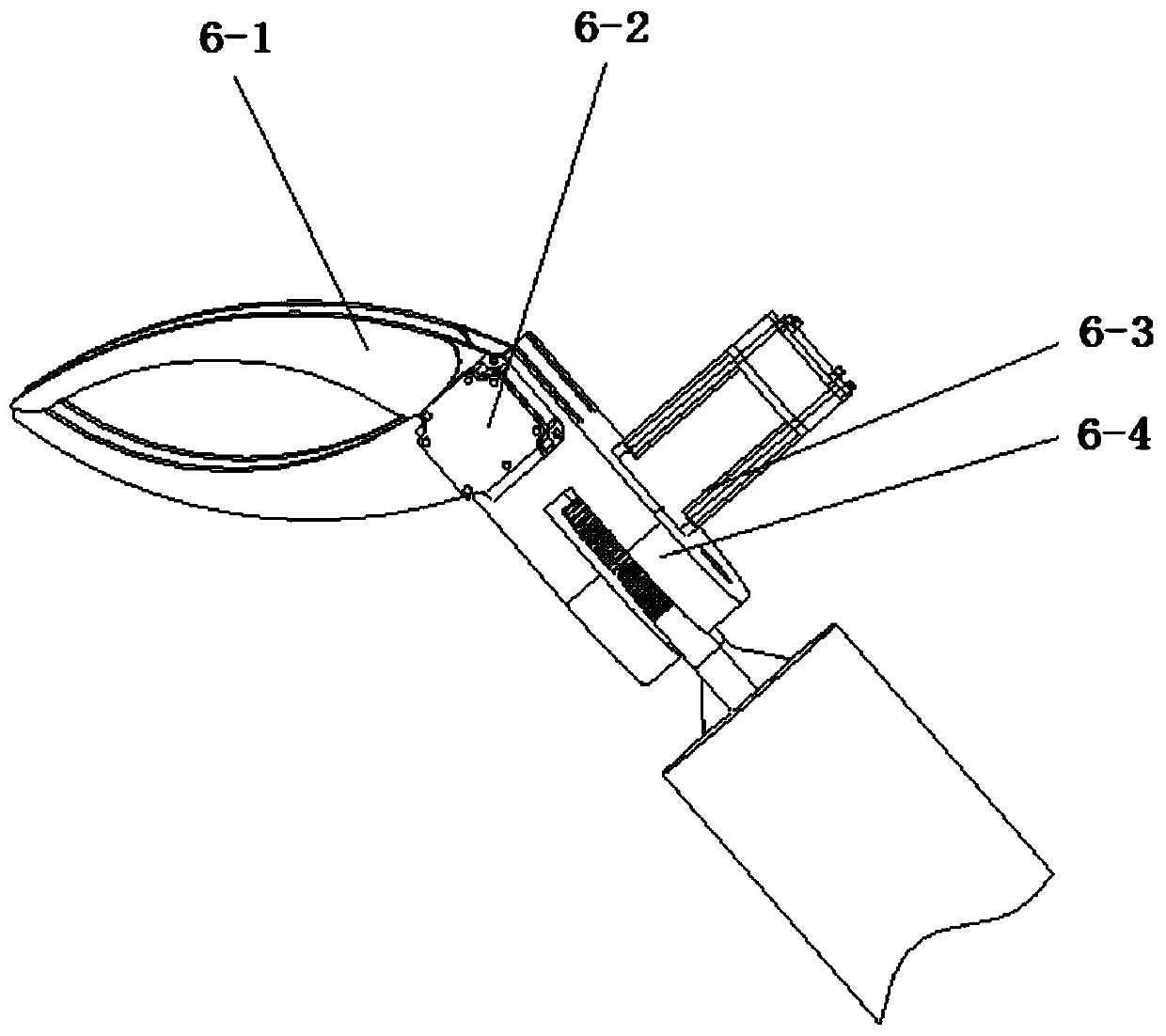

[0025] A machine vision-based robot for precise positioning of building prefabricated components. The box-shaped prefabricated component 2 is hoisted by the spreader 1 to the top of the foundation 4. There are embedded holes at the bottom of the box-shaped prefabricated component and the foundation reinforcement 3 for precise alignment and assembly. Firstly, the box-shaped building prefabricated component is accurately positioned. The robot moves to the vicinity of the box-shaped prefabricated component 2 through the universal wheel 17. The first section visually adjusts the mechanical arm motor 21, the second section visually adjusts the mechanical arm motor 19 and the third section visual adjustment The mechanical arm motor 15 drives the first visual adjustment mechanical arm 22, the second visual adjustment mechanical arm 20 and the third visual adjustment mechanical arm 18 to adjust to a suitable posture, so that the camera 24 can obtain a clear box-shaped prefabricated comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com