Secondary feeding device and feeding method for single crystal furnace

A technology of secondary feeding and single crystal furnace, which is applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of low production efficiency of single crystal silicon rods, long time of single crystal silicon growth, etc., and achieve saving Effect of drawing time, improvement of production efficiency, and avoidance of solid interstitial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

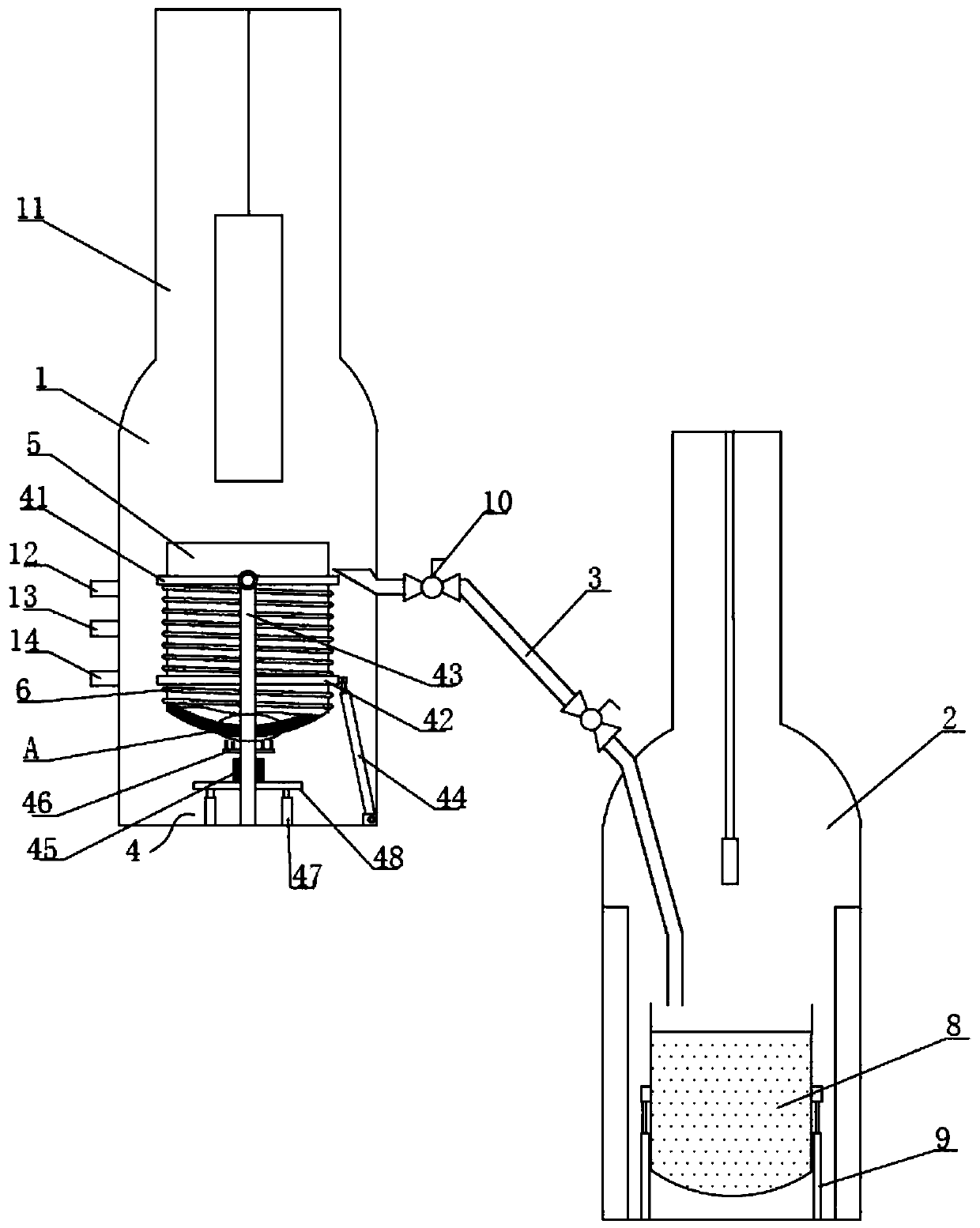

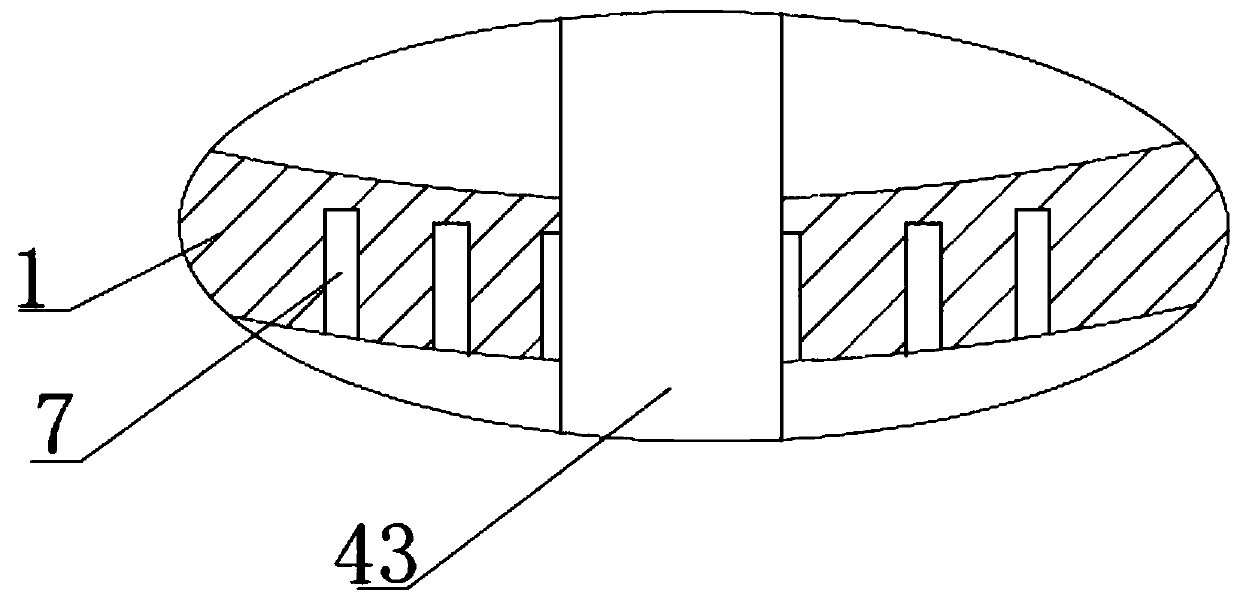

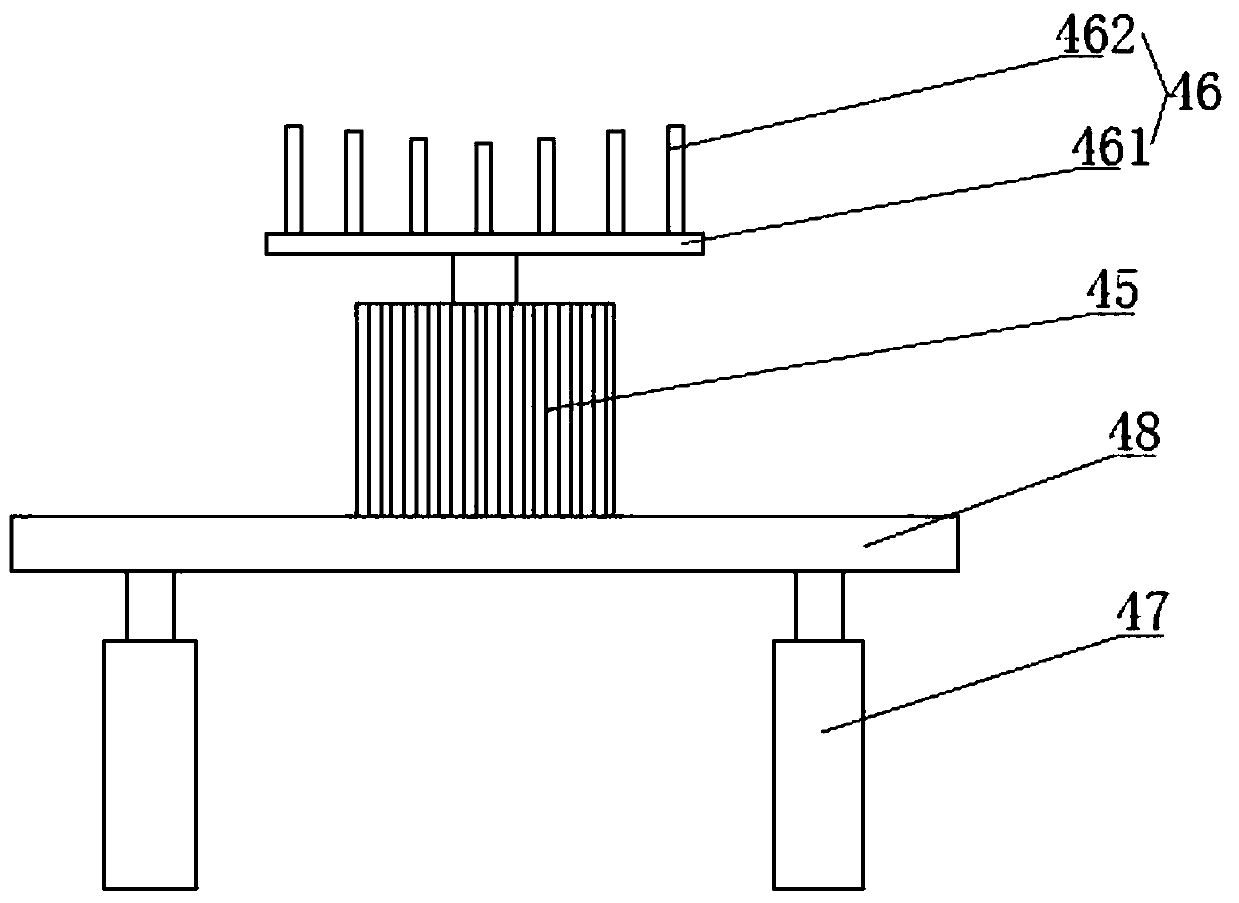

[0036] Figure 1 to Figure 4 Shown is a secondary charging device for a single crystal furnace provided by the present invention, including a charging furnace 1 and at least one single crystal furnace 2, and a plurality of single crystal furnaces 2 are connected to the charging furnace 1 A feeding cylinder 3; a support frame 4 with a dumping function and a chemical material crucible 5 installed on the support frame 4 are installed in the chemical material furnace 1; a heater 6 is also installed in the chemical material chamber.

[0037] The chemical material furnace 1 is used to melt the polycrystalline silicon raw material; the single crystal furnace 2 is used to draw the monocrystalline silicon rod; the feeding cylinder 3 is used to feed the molten polycrystalline silicon raw material in the material chemical fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com