Horizontal butt joint adjusting system and method for binding butt joint of booster and core-level rocket

A technology for regulating systems and boosters, applied to rocket launchers, weapon accessories, weapon types, etc., can solve problems such as low operating efficiency, long time at the launch station, and high skill requirements for operators to improve accuracy and efficiency , the effect of reliable docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

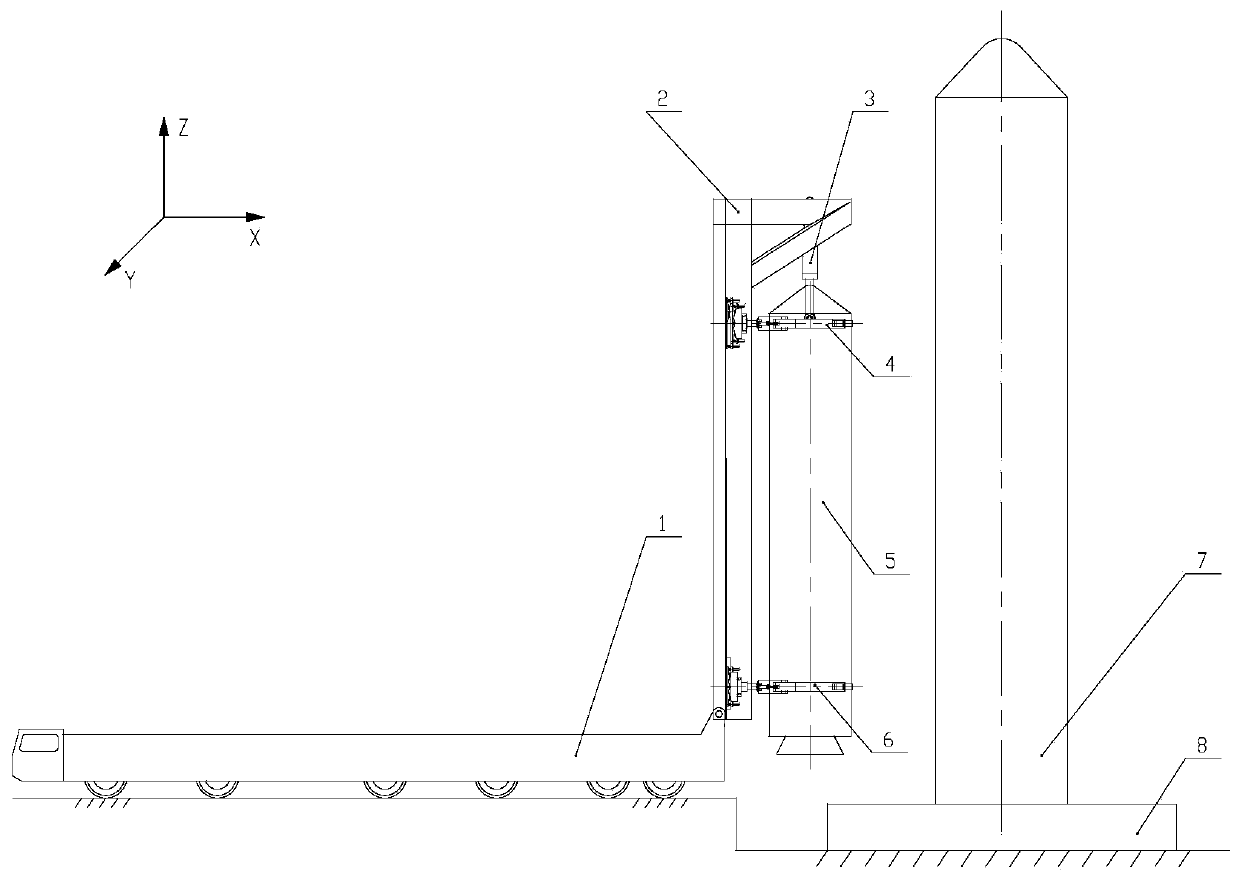

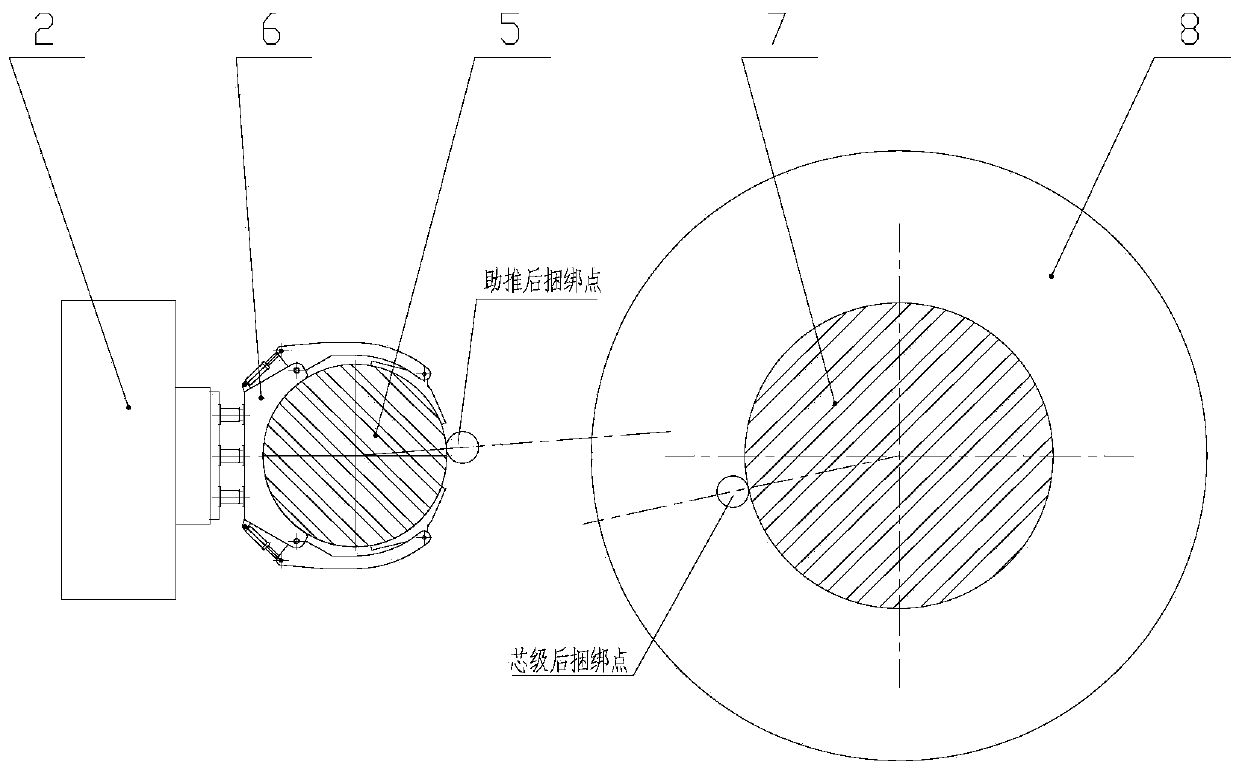

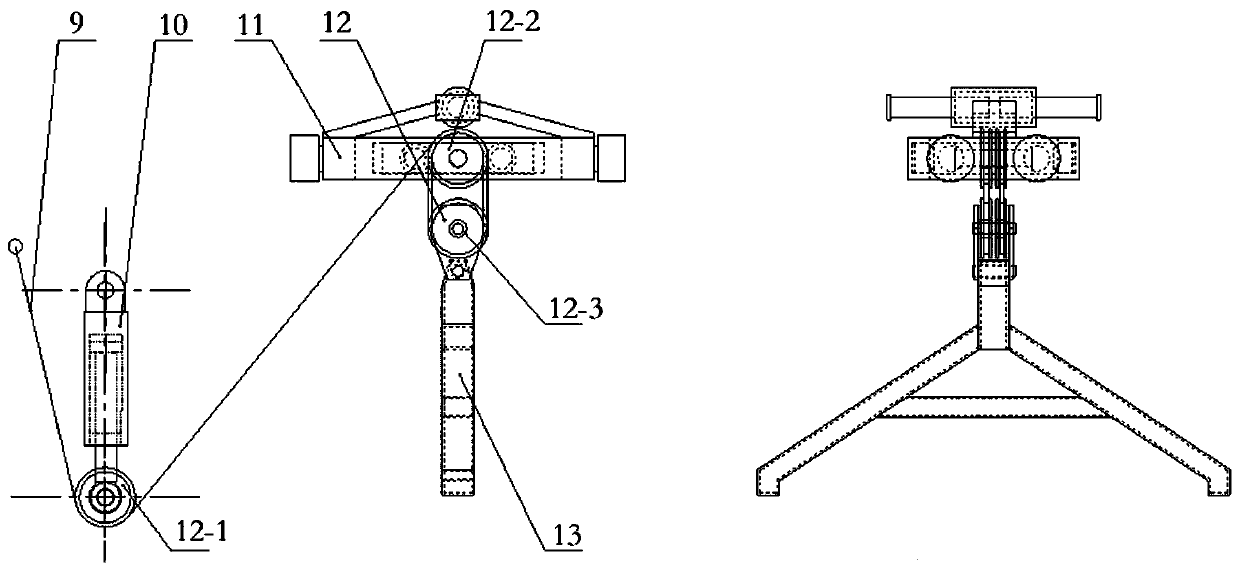

[0029] as attached figure 1 and 2 As shown, the present invention provides a horizontal docking adjustment system for the bundled docking of the booster and the core rocket. The docking adjustment system includes a transport vehicle 1, a vertical arm 2, a lifting adjustment device 3, a front support adjustment device 4, and a rear support adjustment device. Device 6 and rotary launching platform 8 .

[0030] One end of the vertical arm 2 is hinged to the frame of the transport vehicle, and the other end is hinged to the vertical oil cylinder on the transport vehicle. By controlling the expansion and contraction of the vertical oil cylinder, the vertical arm 2 can be rotated 90° around the hinge point with the vehicle frame. , so as to complete the erection of the booster.

[0031] The front support adjustment device 4 and the rear support adjustment dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com