Stepping screw motor defect diagnosis device based on audio analysis and defect recognition method

A technology of audio analysis and defect diagnosis, which is applied to measuring devices, character and pattern recognition, vibration measurement in solids, etc., can solve the problems of comprehensive performance testing and slow testing speed of stepping screw motors, and shorten the testing time. The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

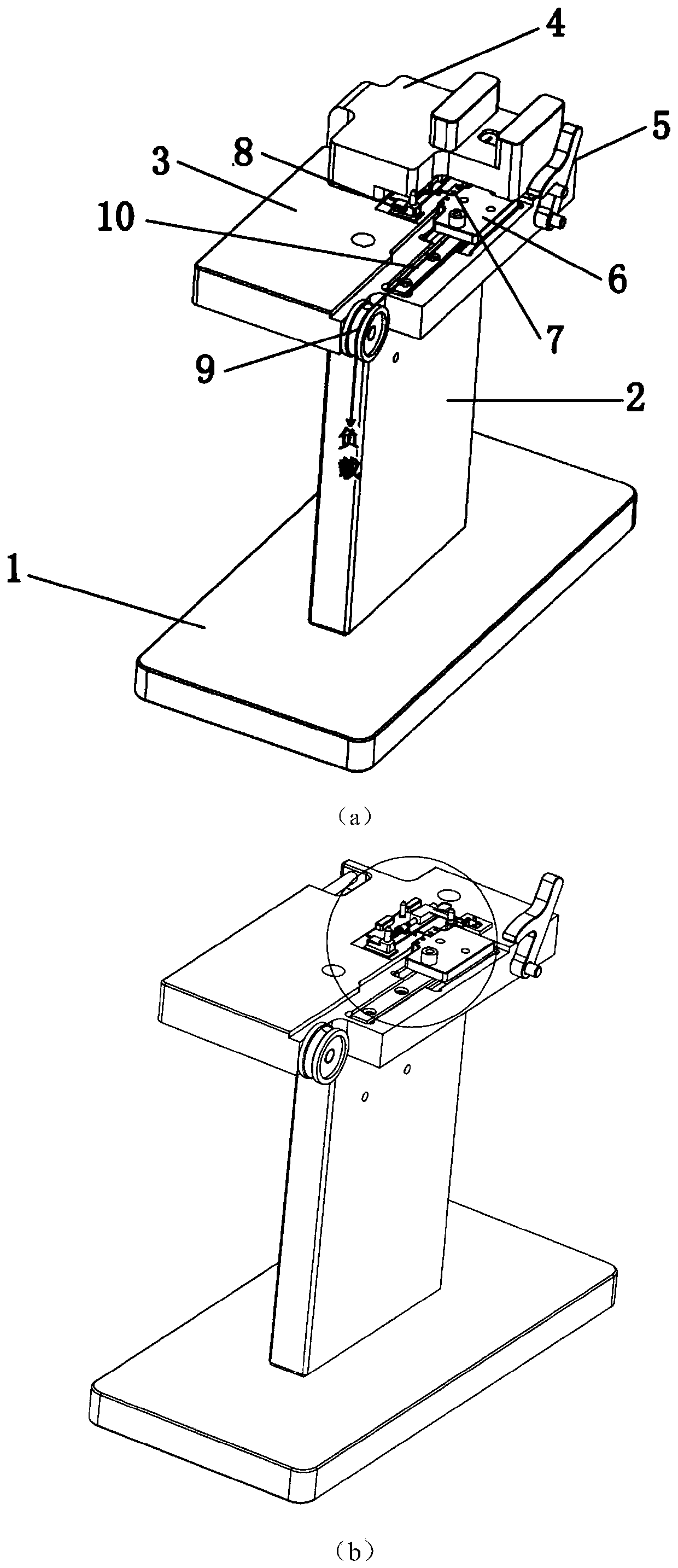

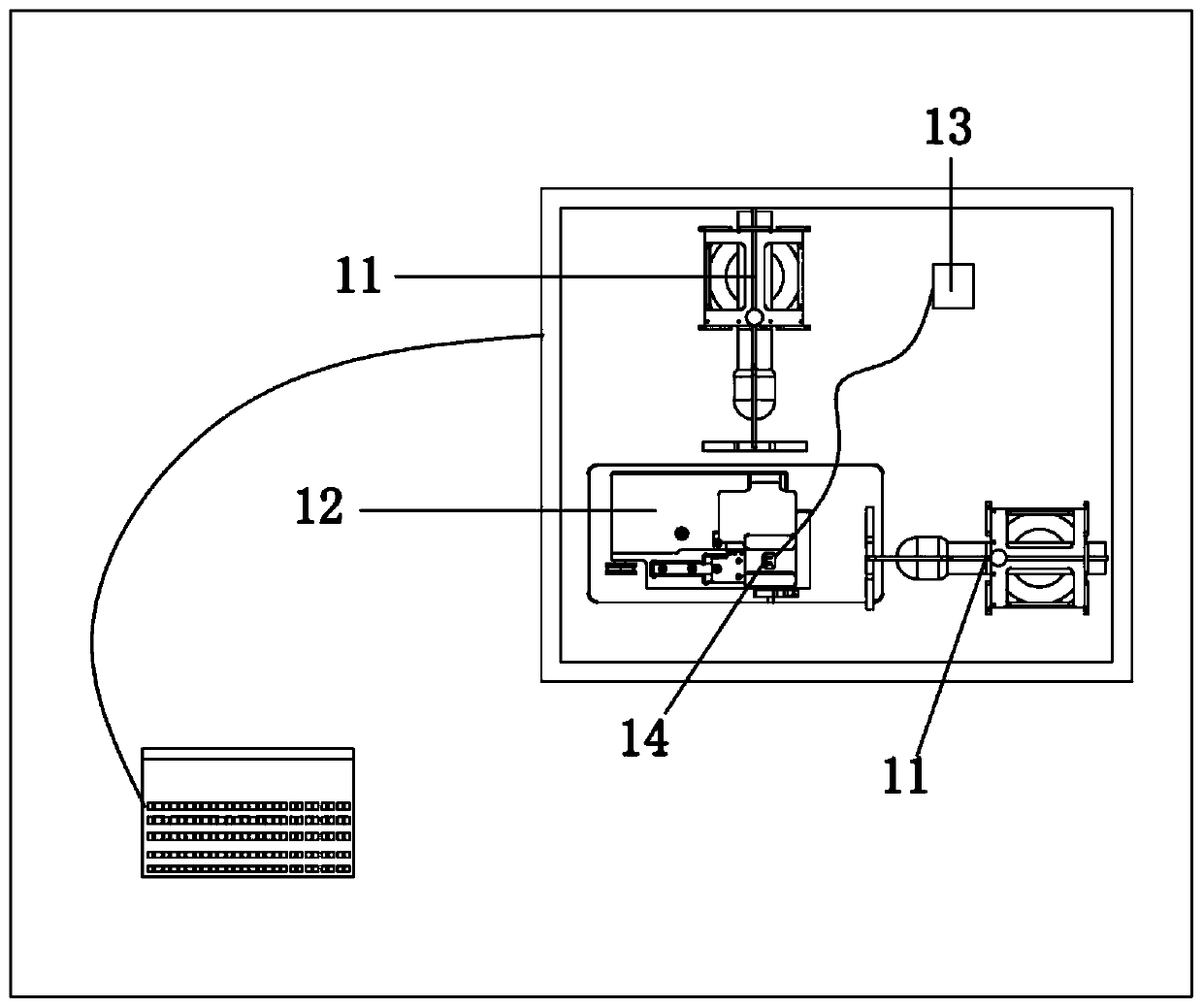

[0079] Embodiment 1 Defect diagnosis device for stepping screw motor based on audio analysis

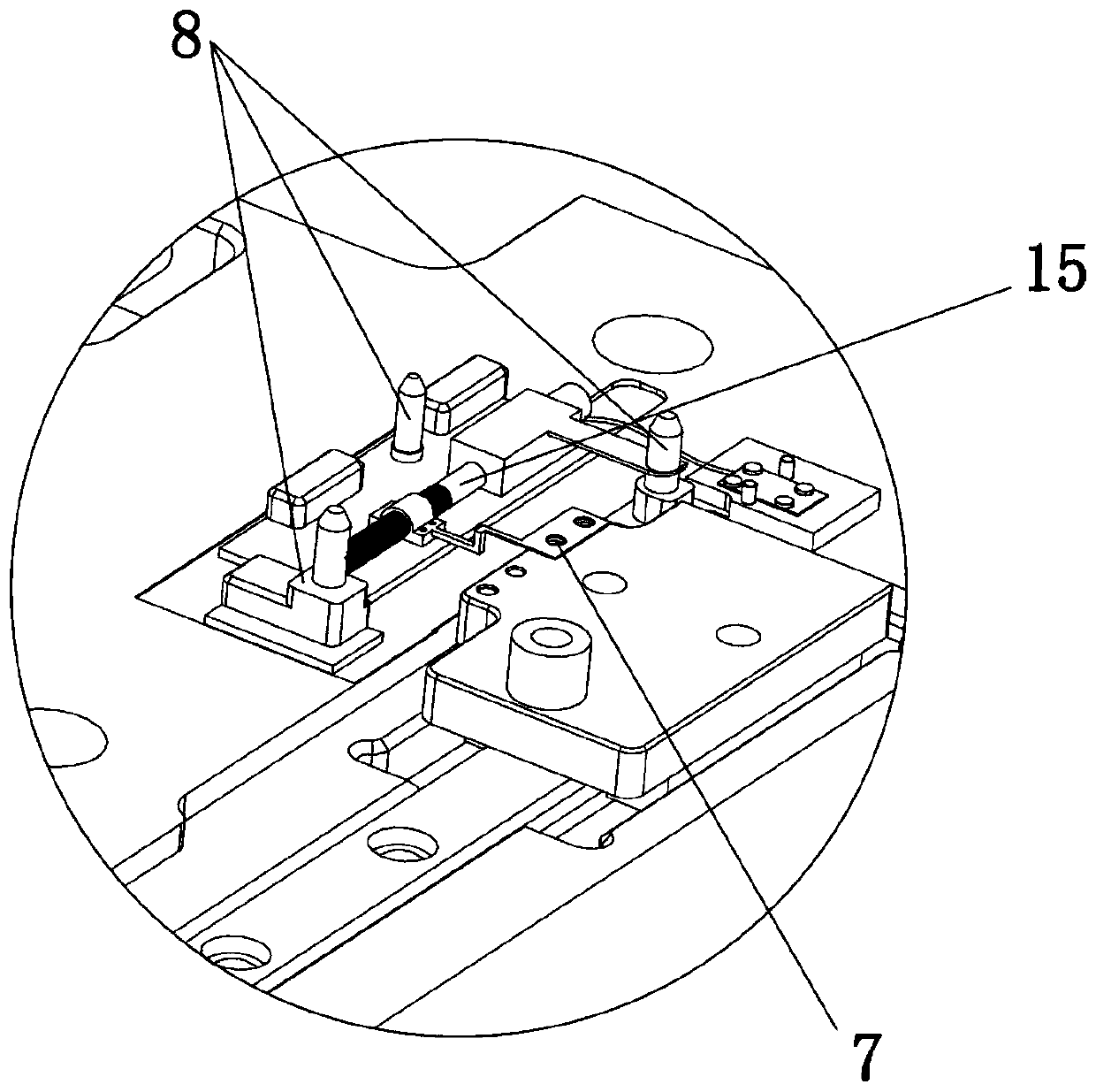

[0080] The stepping screw motor defect diagnosis device based on audio analysis provided by this embodiment, such as Figure 1-5 As shown, it includes a test fixture 12 for installing the stepping screw motor 15 to be tested, a drive board 13 for driving the stepping screw motor 15 to run, and an audio collection mechanism 11 located beside the stepping screw motor 15 , a load pulling mechanism for assisting the operation of the stepping screw motor 15 and load testing, a soundproof box 23 for isolating external noise, and a computer 22 for analyzing audio signals. The soundproof box 23 and the computer 22 are all installed on the anti-vibration workbench 21, and the computer 22 is positioned at the outside of the soundproof box 23.

[0081] Such as Figure 1-2 As shown, the test fixture 12 includes a stage, and a pressing mechanism for pressing and fixing the stepping screw motor ...

Embodiment 2

[0088] Embodiment 2 Defect identification of stepping screw motor based on audio analysis

[0089] In this embodiment, the defects of the stepping screw motor are classified in combination with the decibel value and the noise. The setting standard for the defect of the stepping screw motor 15 is: the decibel value exceeds the threshold and the accompanying noise is a noise part; the decibel value If the decibel value does not exceed the threshold and is accompanied by noise, it is a piece of abnormal sound; if the decibel value does not exceed the threshold and there is no noise, it is a good product.

[0090] In this embodiment, the decibel threshold and the noise judgment standard are firstly determined through an orthogonal experiment.

[0091] 1. Orthogonal test

[0092] Select a number of step screw motor 15 standard workpieces (including normal workpieces without defects) with various types of defects (noise, excessive sound, abnormal sound and good product (ie no defec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com