Combined assembly type high-voltage live-line work comprehensive shielding device and using method thereof

A high-voltage electrification and shielding device technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficult to fix wires of different specifications, easy gaps in shielding covers, inconvenient use and carrying, etc., so as to facilitate positioning and installation and improve heat dissipation Effects, effects that are easy to use and carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings of the specification, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

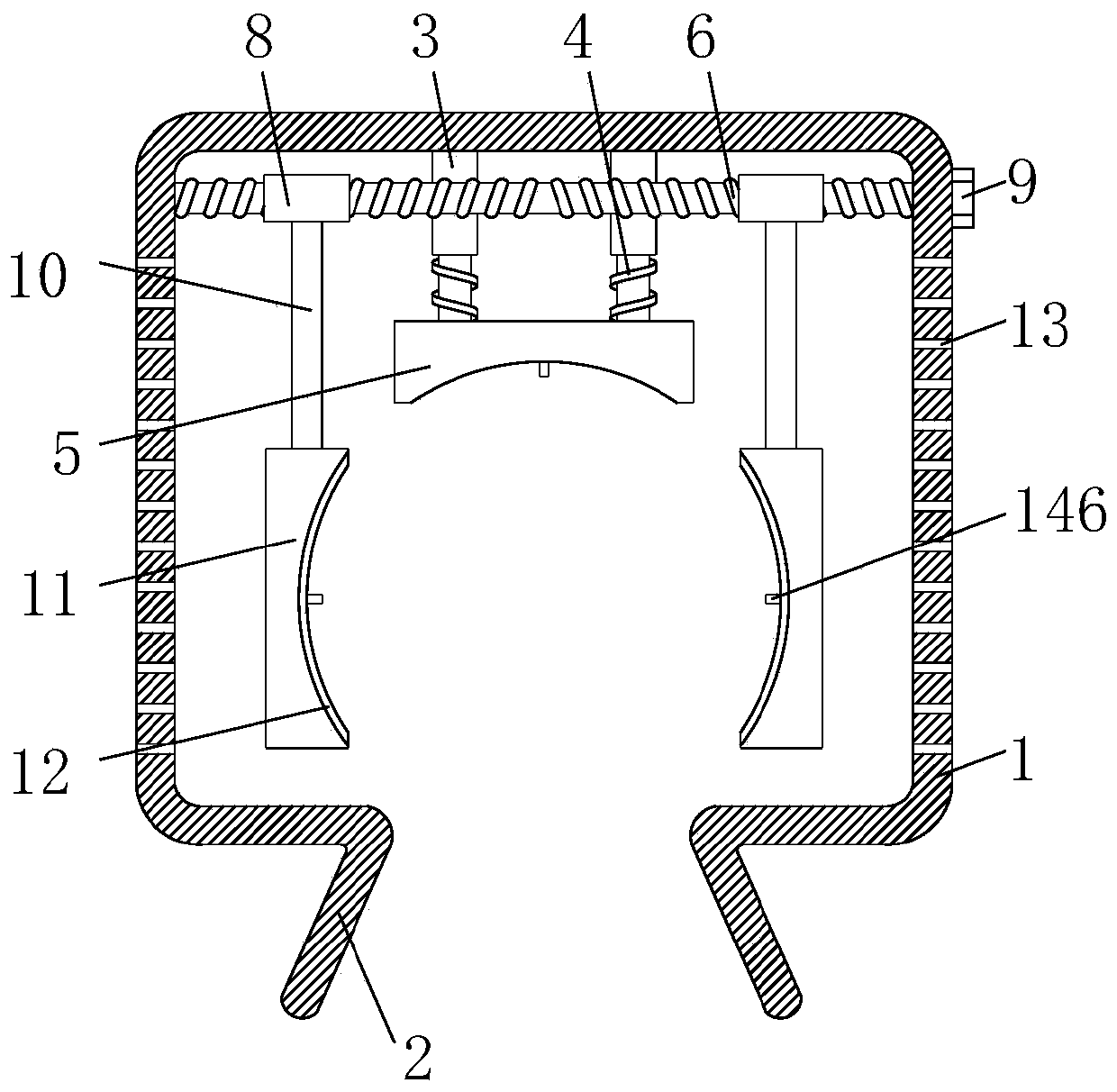

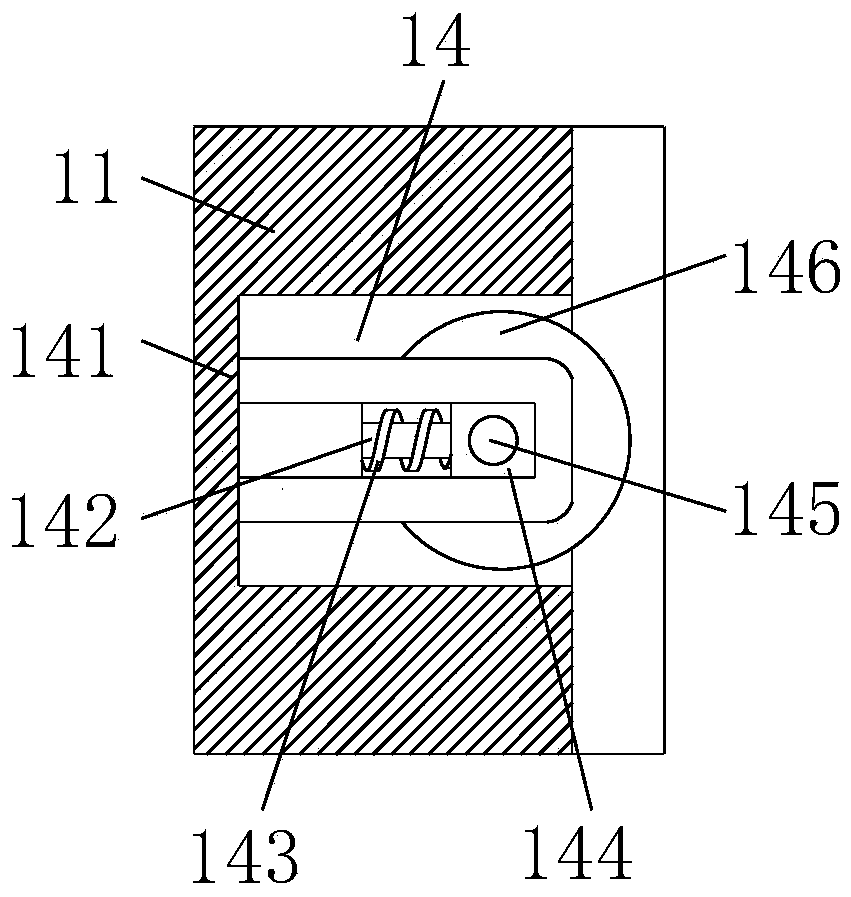

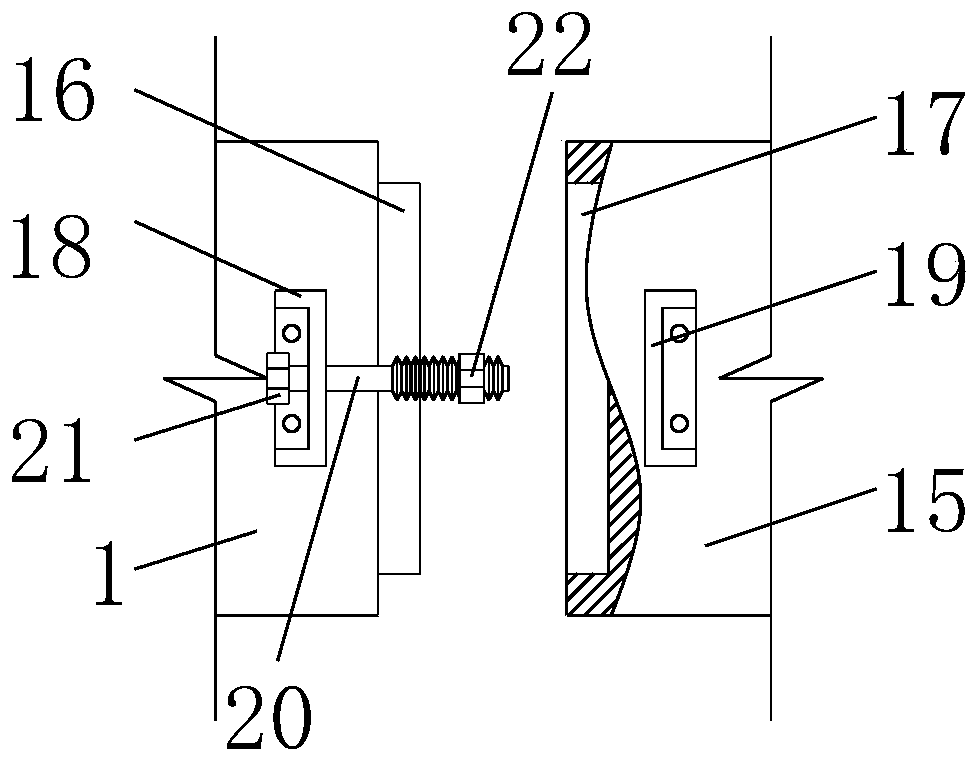

[0025] see Figure 1-Figure 4 , A combined and assembled high-voltage live working full-scale shielding device, comprising a first shielding cover 1 and a second shielding cover 15. The first shielding cover 1 and the second shielding cover 15 have the same structure, and both have a frame structure with an open bottom; The adjacent sides of the first shielding cover 1 and the second shielding cover 15 are provided with a positioning block 16 and a positioning slot 17 respectively. The positioning block 16 and the positioning slot 17 are inserted into each other; the first shielding cover 1 and the second shielding cover 1 A left fixing seat 18 and a right fixing seat 19 are respectively fixed on the top of the shielding cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com