Proportional valve for controlling a gaseous medium

A gaseous medium and proportional valve technology, applied in the field of proportional valves, can solve the problems of proportional valve wear, increased switching force load of the electromagnet, and wear of the valve seat, and achieve the effects of simple structure assembly, guaranteed sealing, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

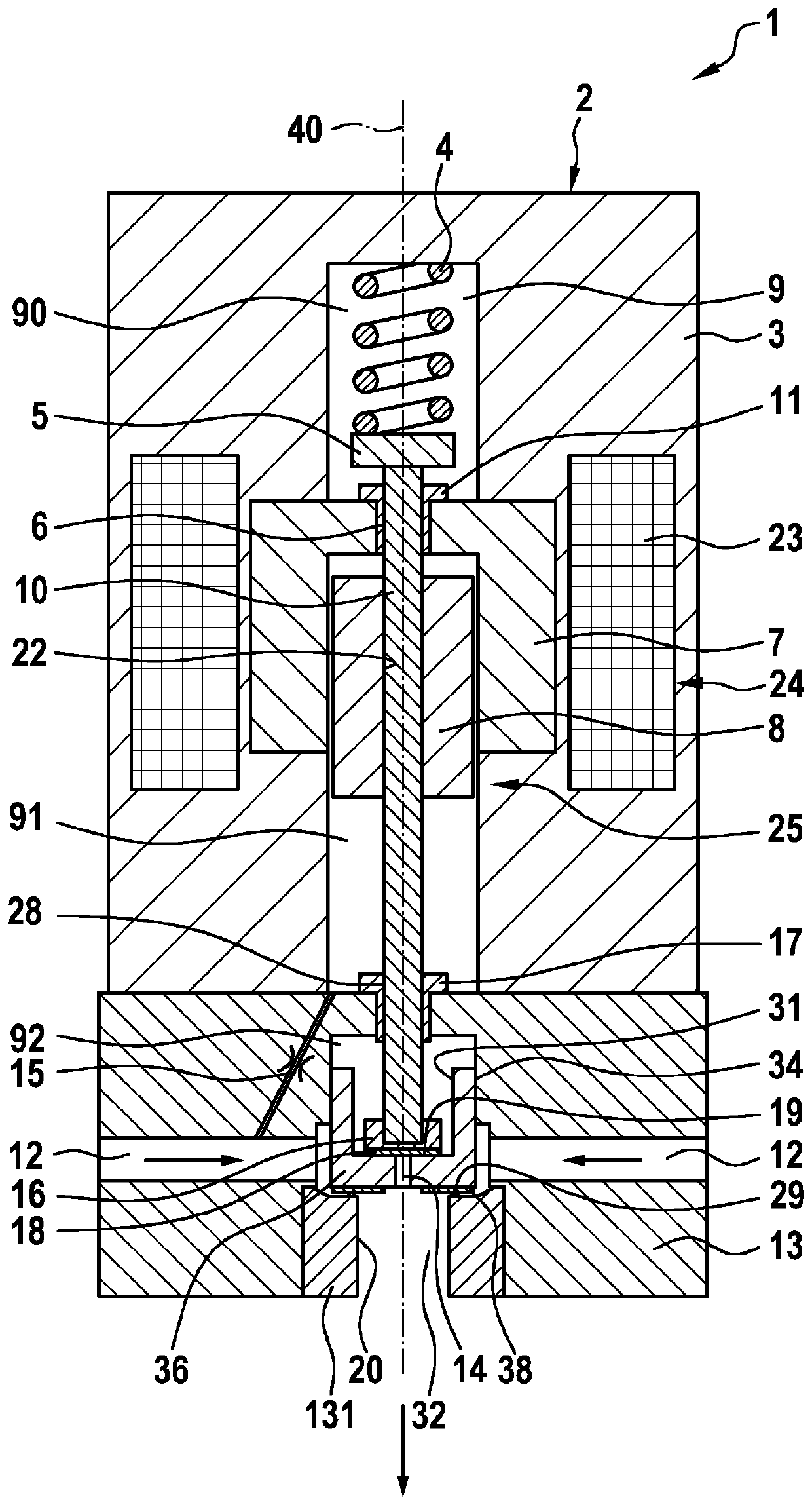

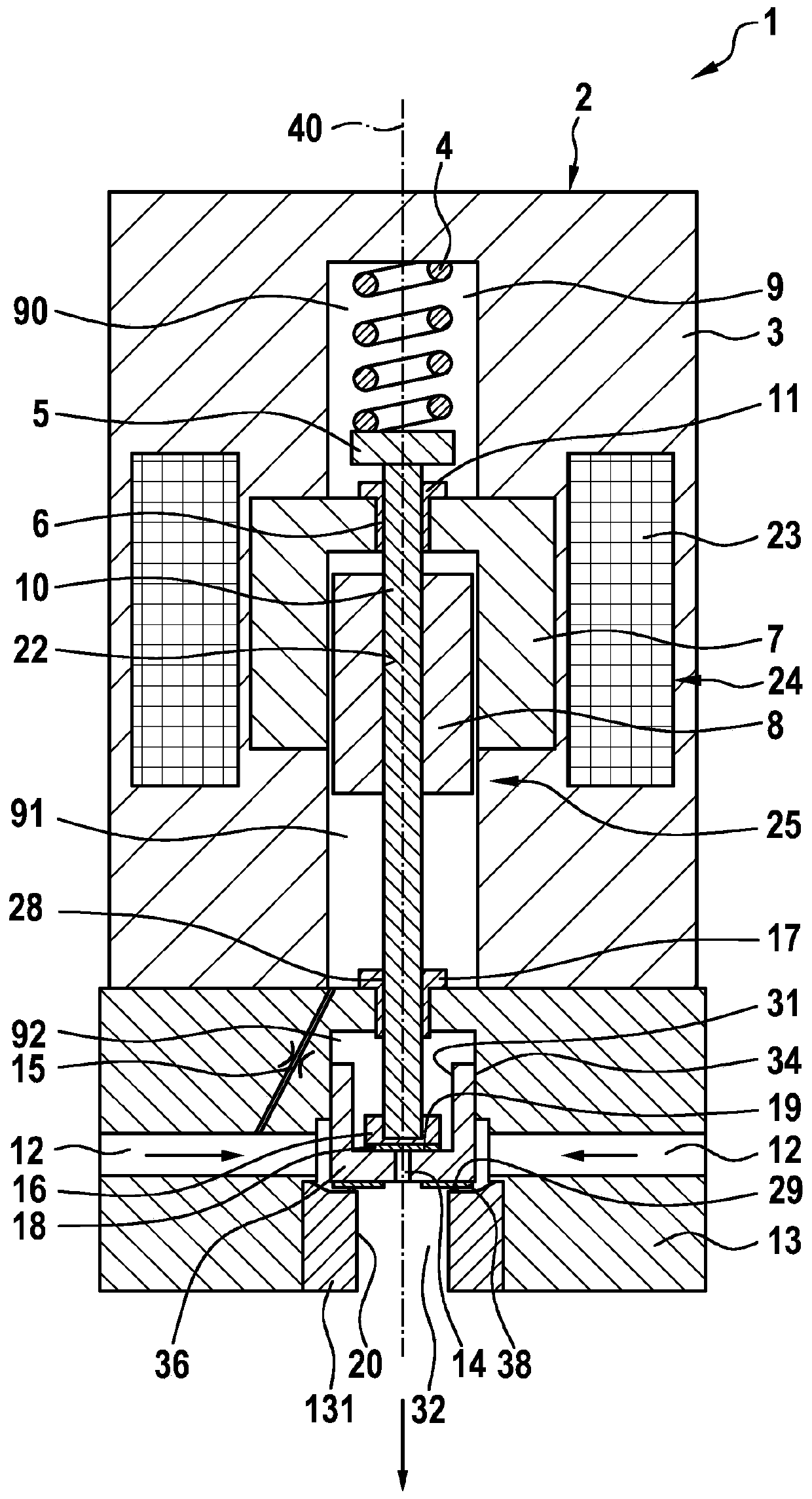

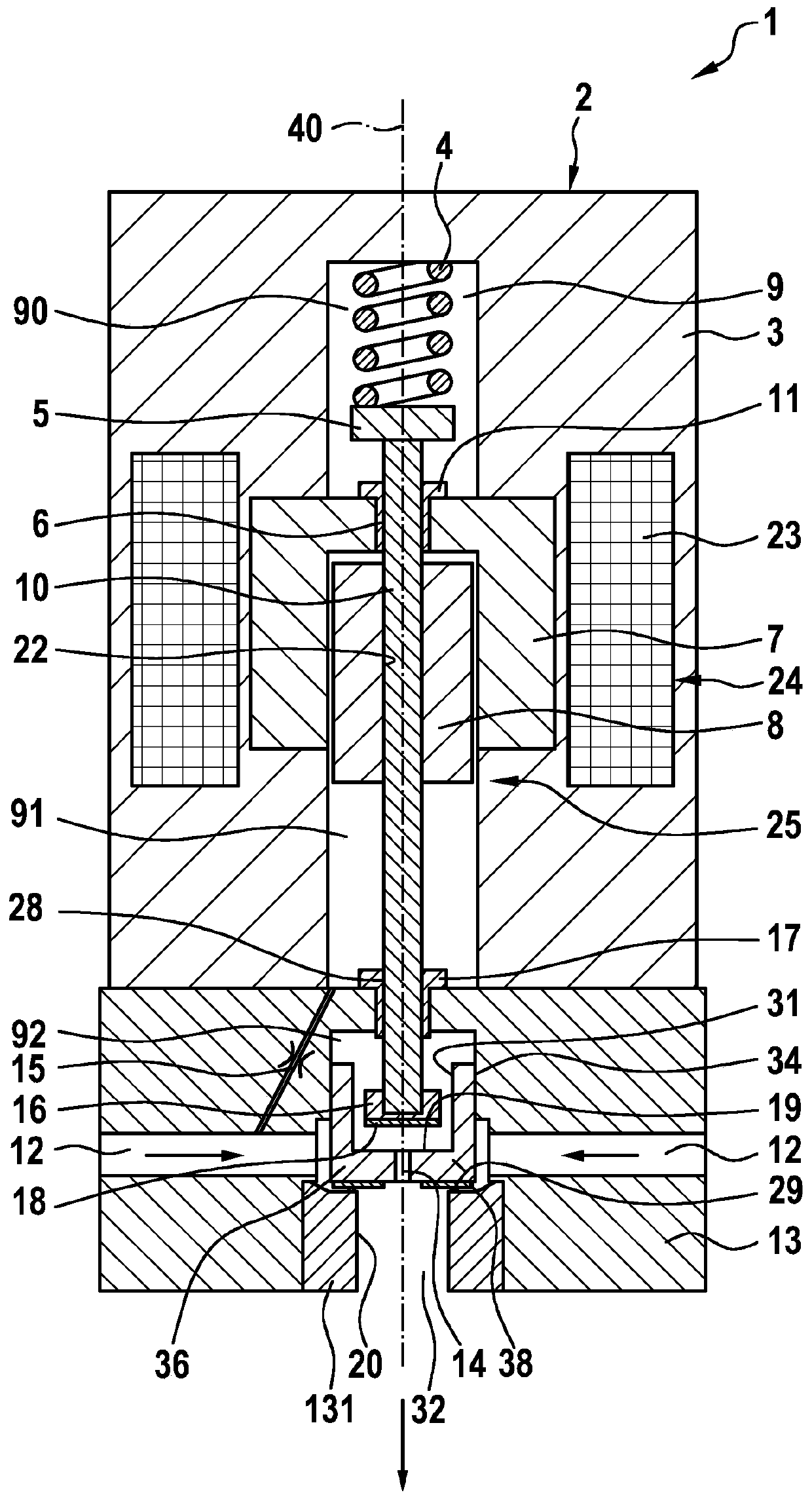

[0026] figure 1 A first exemplary embodiment of the proportional valve 1 according to the invention is shown in longitudinal section. The proportional valve 1 has a valve housing 2 , wherein the valve housing 2 comprises a holding body 3 and a nozzle body 13 , which are gas-tightly connected to each other. A nozzle 131 is received in the nozzle body 13 . An electromagnet 24 is arranged in the proportional valve 1 , wherein the electromagnet 24 includes a solenoid coil 23 and a magnetic core 7 . Furthermore, an inner chamber 9 is formed in the valve housing 2 , in which an electromagnetic armature arrangement 25 is arranged to be movable.

[0027] The magnet armature arrangement 25 comprises the magnet armature 8 and a cylindrical connecting element 10 , wherein the connecting element 10 is received in a recess 22 of the magnet armature 8 and is thus fixedly connected to the magnet armature 8 , for example by a welding seam or by pressing. . Electromagnetic armature 8 is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com