Industrial robot carrying device, system, method and machine-readable medium

A technology of industrial robots and handling systems, applied in the field of industrial production, can solve the problems of low efficiency of industrial robots and manual completion, and achieve the effects of balanced force, handling guarantee, and rationality guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

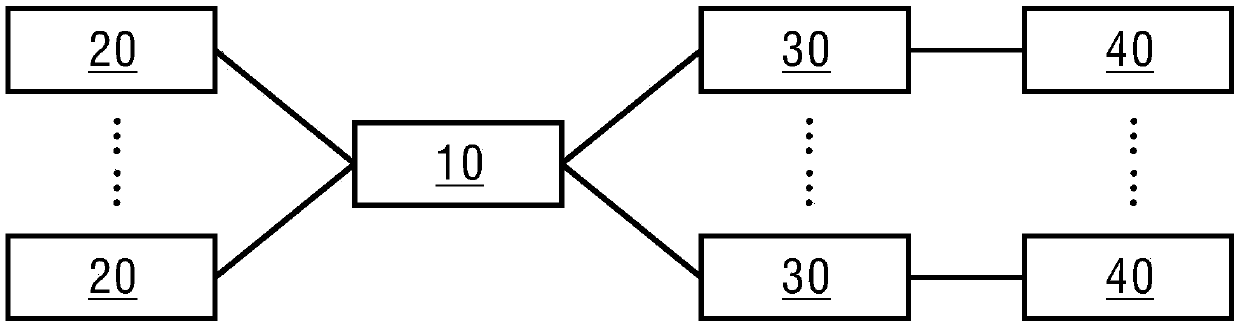

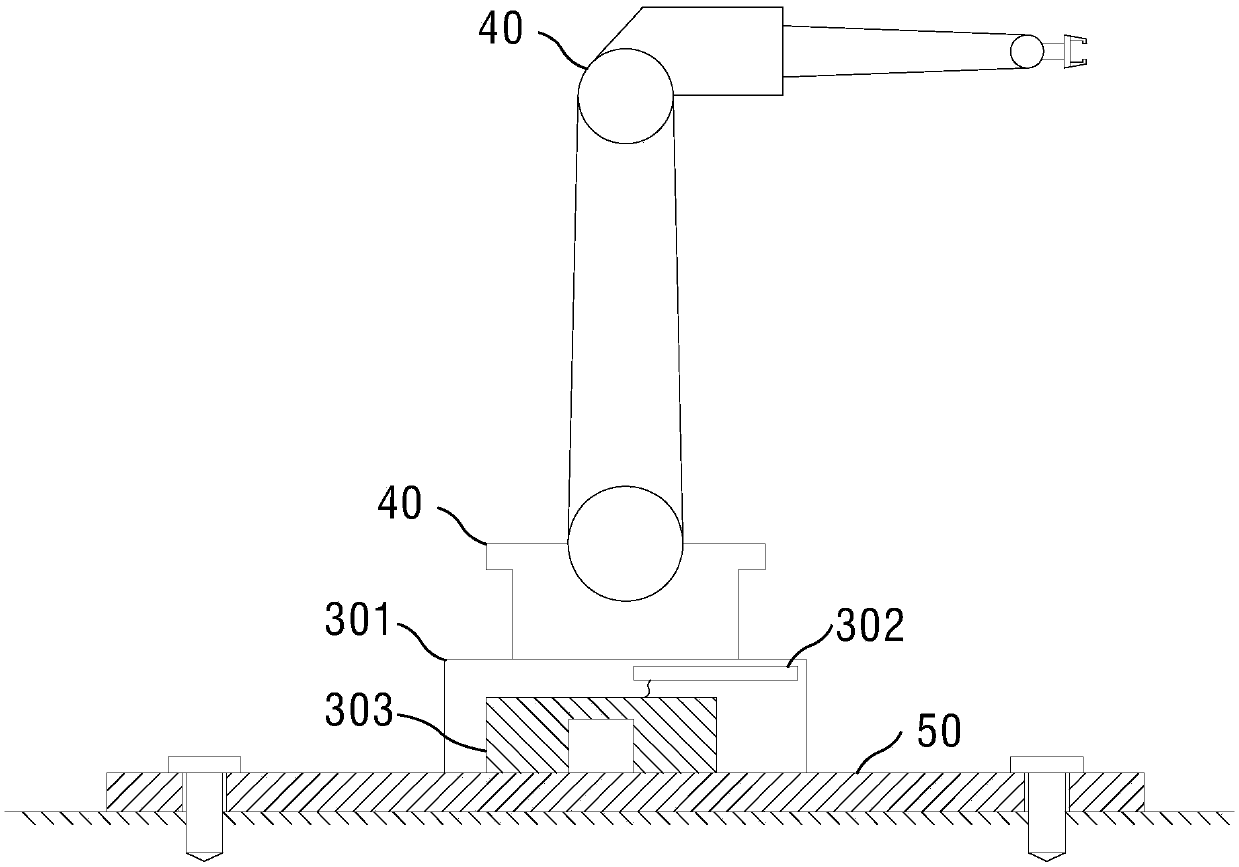

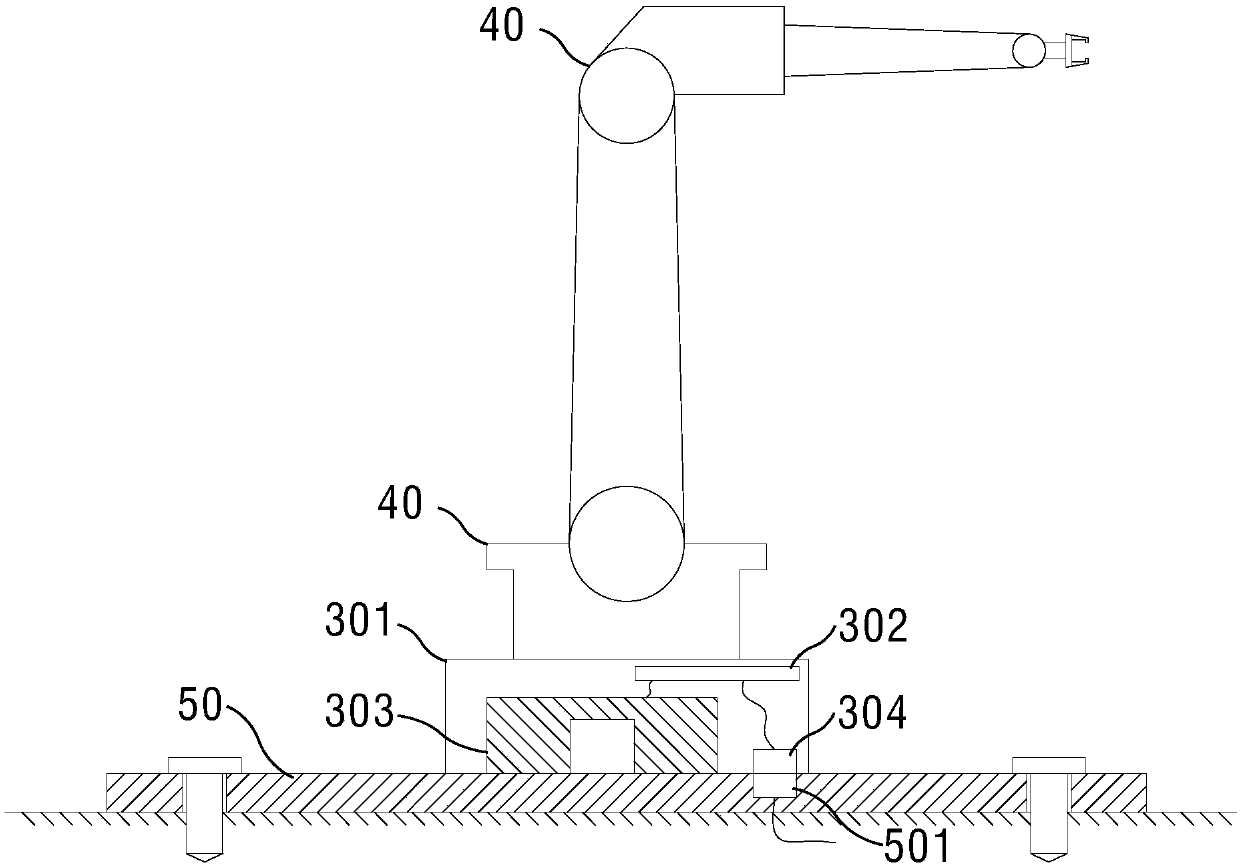

[0111] As mentioned above, the industrial robots currently deployed in factories are usually fixed on the ground by bolts. When the industrial robots need to be transported, the bolts that fix the industrial robots need to be removed first, and then the industrial robots should be transported to the ground by a crane or forklift. The target position, and then fix the industrial robot with bolts. Since the disassembly and assembly of bolts and the handling of industrial robots by cranes or forklifts need to be completed manually on site, and it takes a long time for workers to disassemble and assemble bolts and transport industrial robots on site, resulting in low efficiency of industrial robot handling.

[0112] In the embodiment of the present invention, the industrial robot is installed on the electromagnetic base, and the electromagnetic base can absorb the metal plate fixed on the ground to realize the fixing of the industrial robot. When an industrial robot needs to be tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com