An automatic film sticking mechanism

A film sticking mechanism and template technology, which is applied to household components, home appliances, other home appliances, etc., can solve the problems of easy positioning errors of workers, difficult to guarantee the quality of the film, and high labor intensity of workers, so as to reduce the cost of the film and ensure the quality of the film. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

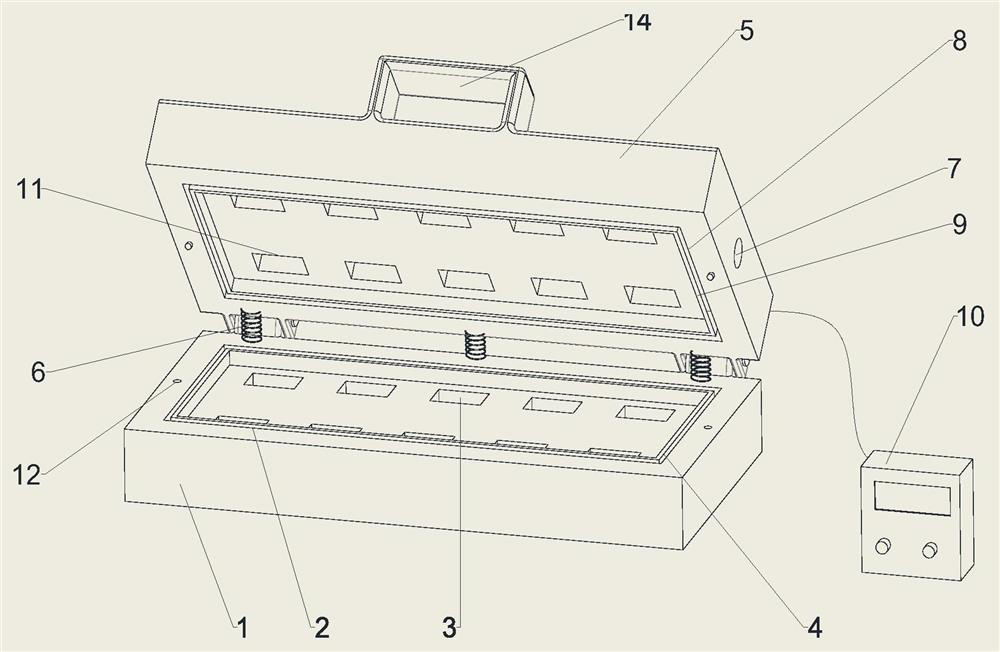

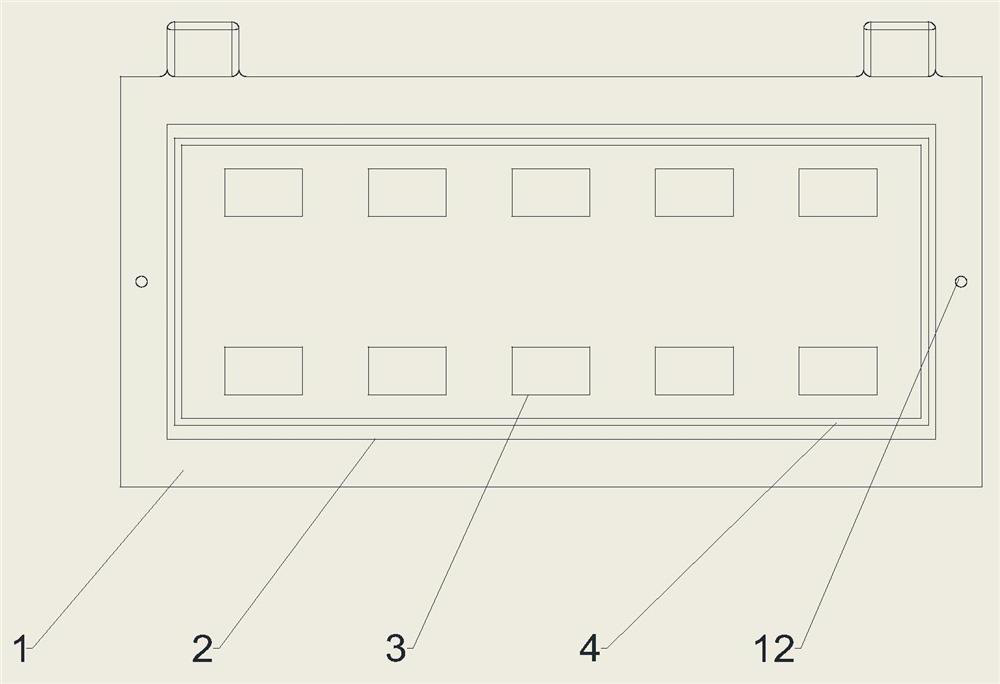

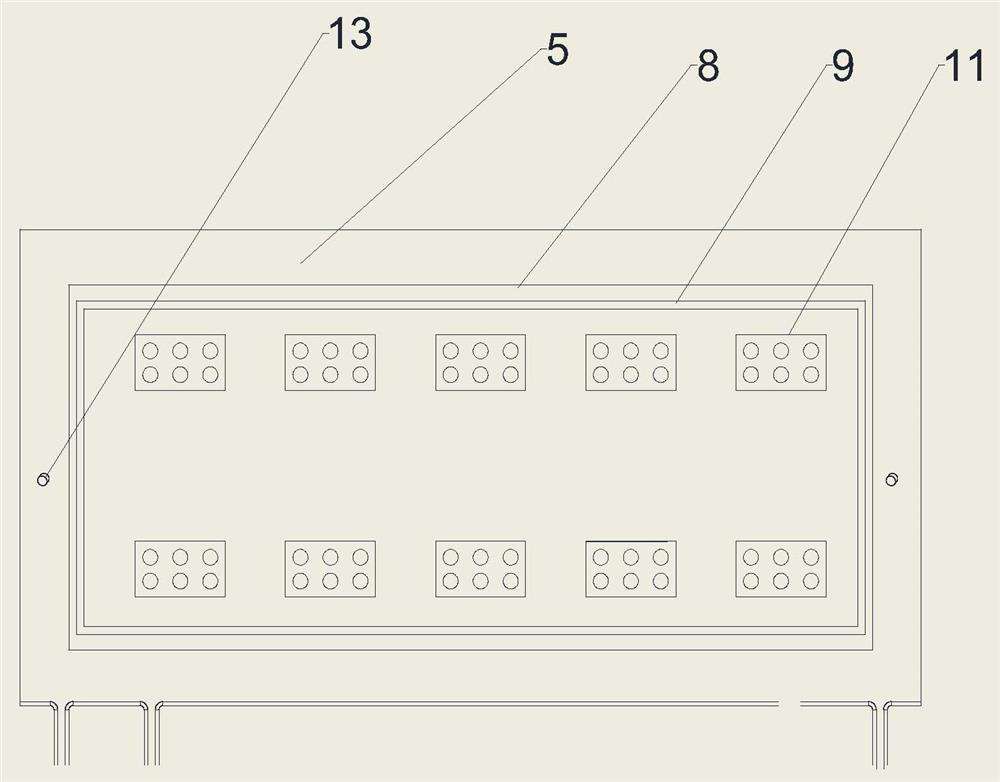

[0020] Such as figure 1 , figure 2 and image 3 As shown, an automatic film sticking mechanism includes a lower template 1, a placement part 2 is embedded on the lower template 1, and a plurality of detachable placement slots 3 and permanent magnets 4 surrounding the placement slots 3 are provided on the placement part 2. In the embodiment, since a product is placed in each placement groove 3, multiple products can be pasted at the same time, thereby greatly improving work efficiency; and because the placement part 2 is screwed to the placement groove 3, it can According to the different products that need to be pasted with film, the placement groove 3 is matched and replaced, thereby expanding the scope of application of the mechanism. The side wall of the lower formwork 1 is also hinged with a matching upper formwork 5, and a number of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com