Novel counterweight device of high-speed wire packing machine

A technology of counterweight device and high-speed wire, which is applied in the direction of bundling materials and parts of bundling machinery, etc. It can solve the problems of reducing the grooving rate of packing wire, difficult maintenance of counterweight wheels, and shortening maintenance time, etc., to shorten maintenance time , Long maintenance time and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

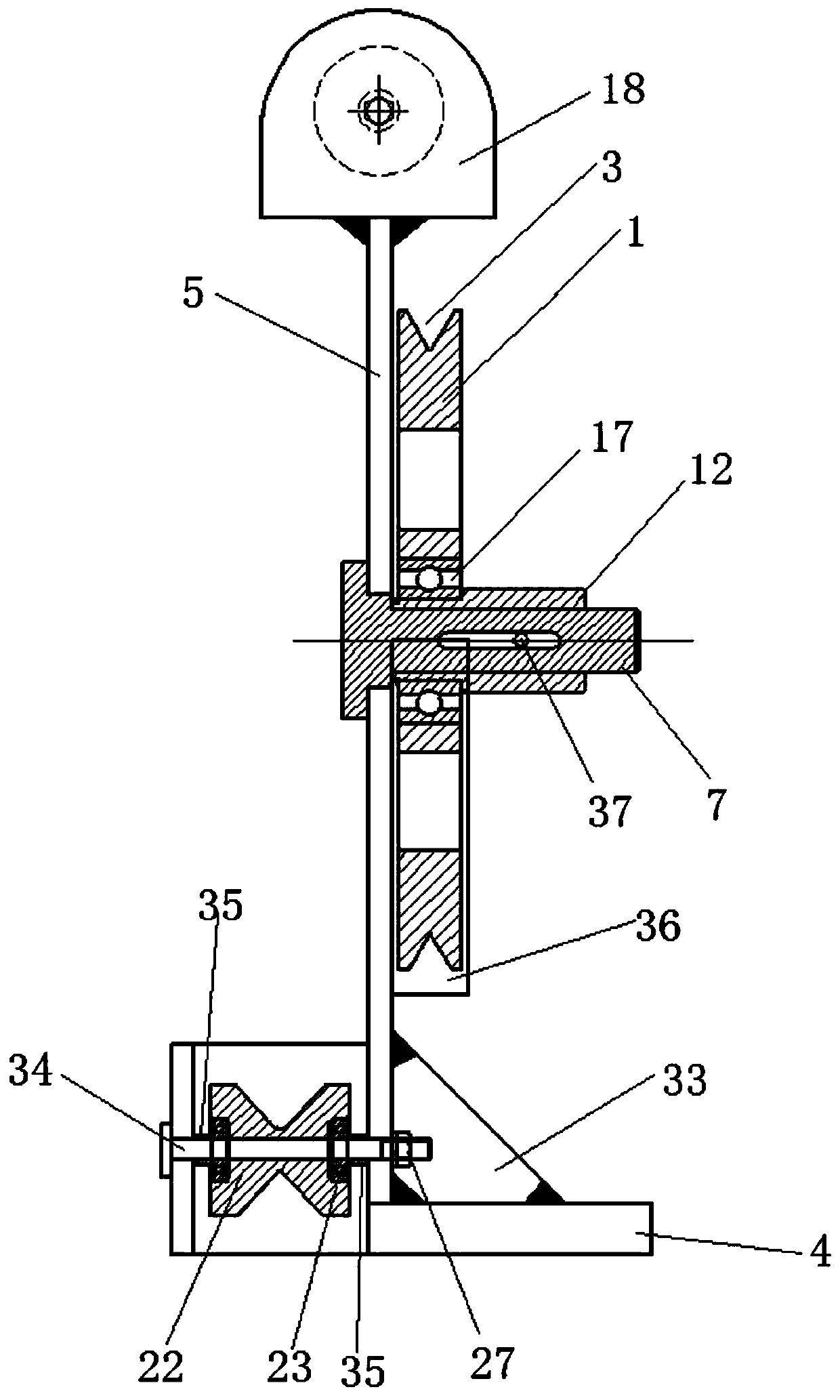

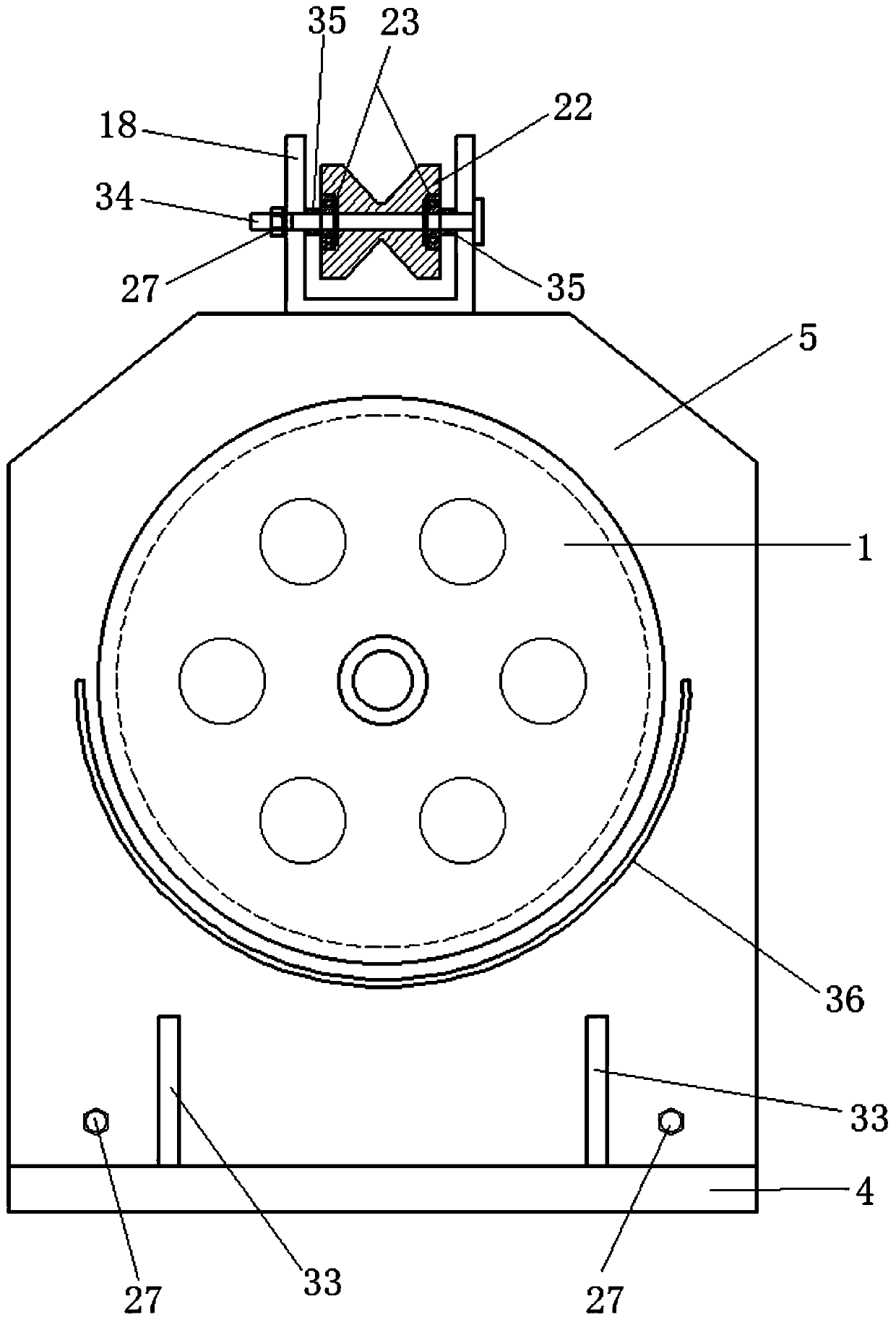

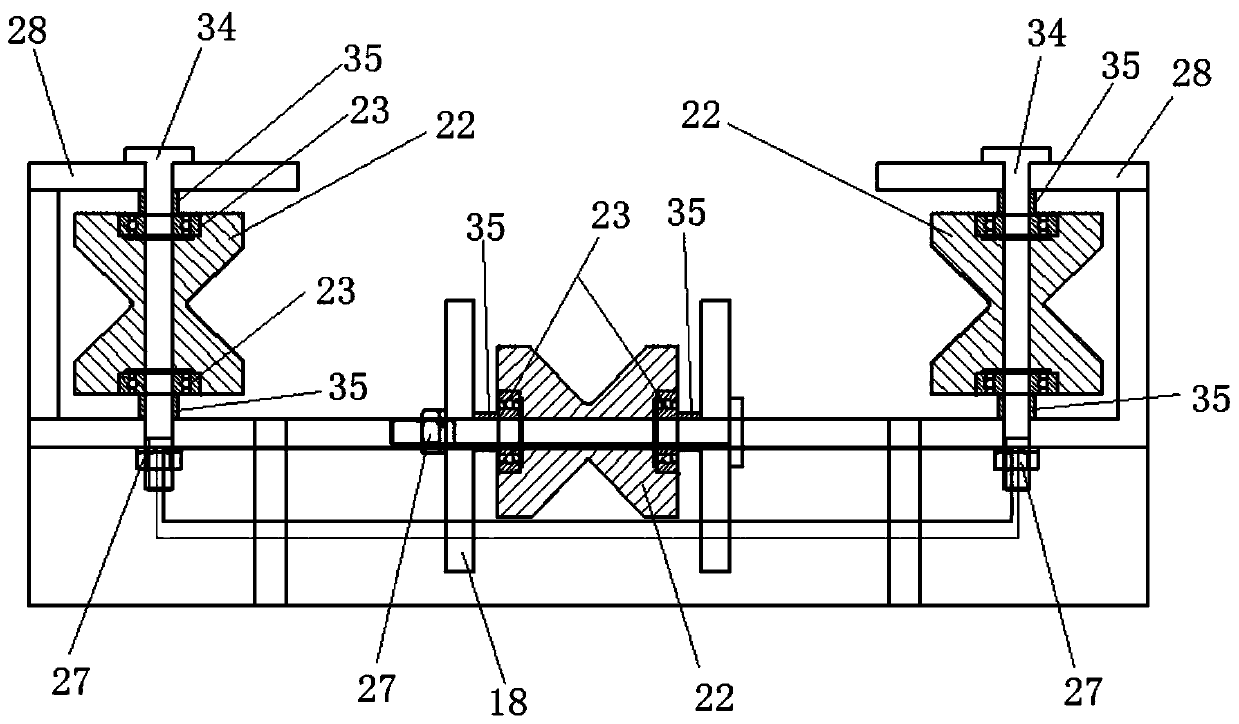

[0059] The embodiment of the present invention provides a high-speed wire packing machine counterweight device, please refer to Figure 1-17 , the counterweight device includes:

[0060] A counterweight wheel 1, the center of the counterweight wheel 1 is provided with a first mounting hole 2, and the side of the counterweight wheel 1 is provided with a first groove 3;

[0061] Further, the weight wheel 1 is integrally formed.

[0062] Further, the cross section of the first groove 2 is triangular.

[0063] Specifically, the weight wheel 1 is integrally formed, the weight wheel 1 is circular, and the center of the weight wheel 1 is provided with a first mounting hole 2, and the first mounting hole 2 It is a circular through hole passing through the axis direction of the weight wheel 1 . The first mounting hole 2 is used to install the first bearing 17, and the diameter of the first mounting hole 2 matches the outer diameter of the first bearing 17. The first groove 3 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com