Design method of high-lift centrifugal pump for conveying liquid easy to vaporize

A technology of vaporizing liquid and design method, which is applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of poor anti-cavitation performance, difficult rotor maintenance, and many impeller stages, etc., and achieves low cost, rotating Small inertia and the effect of expanding low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

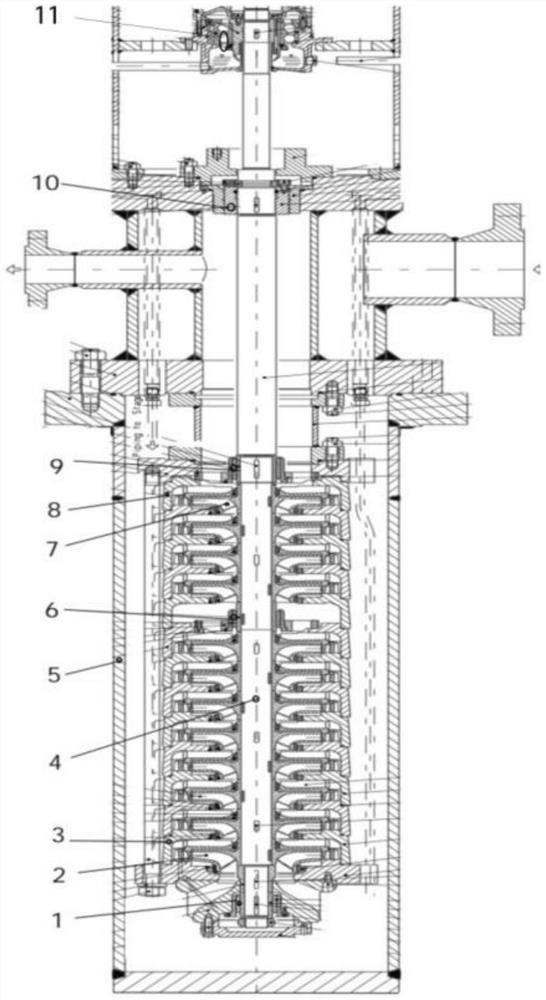

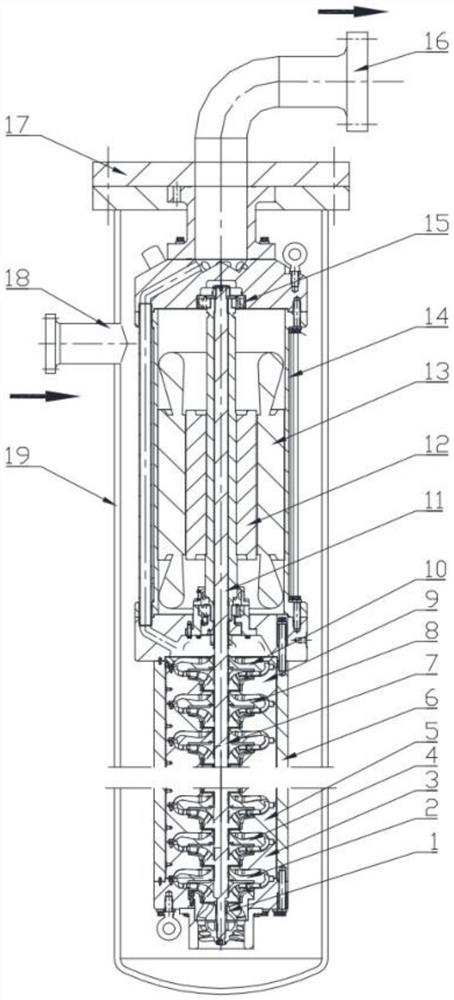

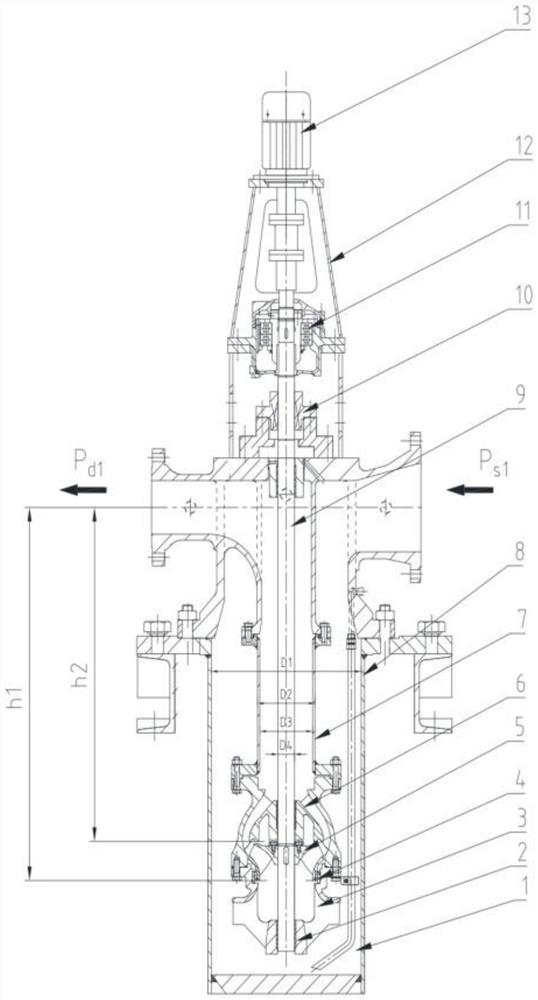

[0057] The following is an engineering example in the article "Engineering Example of Vertical Barrel Pump for Extremely Vaporizable Medium" searched on Baidu website and the attached manual. image 3 , to describe the design method of the present invention in detail, so as to facilitate the public to fully understand and realize the design method of the present invention.

[0058] An ethylene project of a Sinopec company, ethylene liquid delivery pump. Physical properties of liquid ethylene: temperature -35°C, specific gravity 0.449, vapor pressure 1.69MPa.A, viscosity 0.077cP. Pump parameters: flow rate 100m 3 / h, head 977m, speed 2980RPM, pressure at the center line of the pump inlet connection 1.694MPa.A, where the pressure of ethylene is only 0.004MPa higher than the vaporization pressure, ethylene is close to the vaporization state and there is a risk of cavitation, the first stage impeller must be Drop below the ground. Pump model TTMC80-230(B)×13, impeller 13 stages...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com