Silicon wafer interlayer configuration mechanism

A technology of interlayer and silicon wafer, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of cumbersome boxing, high dependence on personnel, and increased boxing costs, so as to prevent insufficient supply of materials and ensure real-time monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

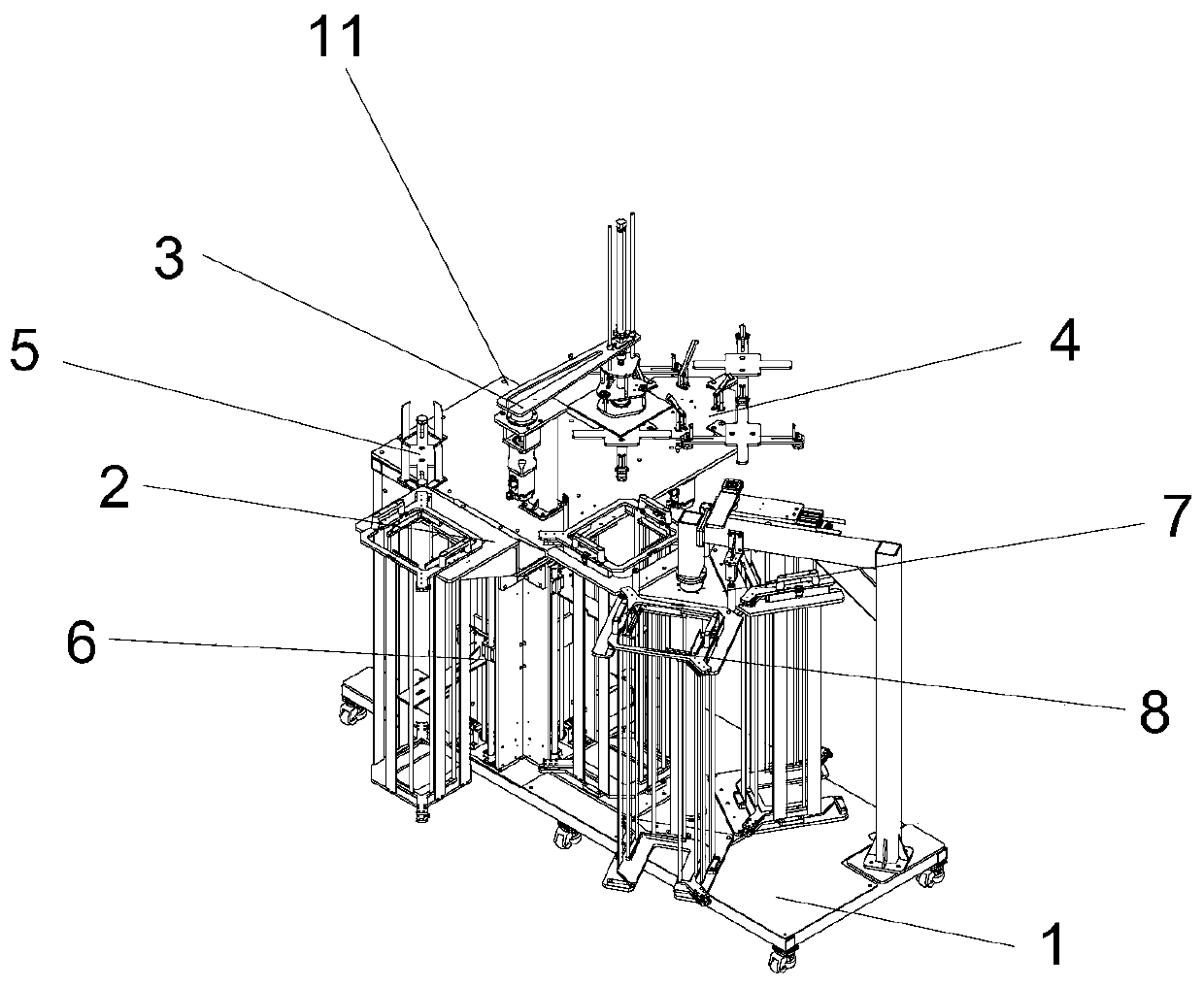

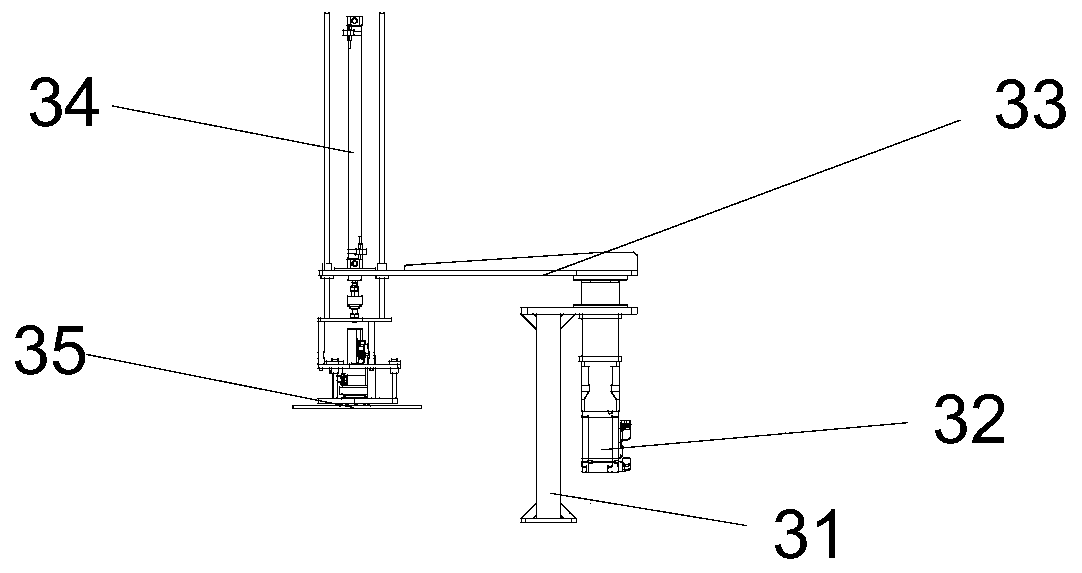

[0033] In the process of packaging silicon wafers, a certain number of silicon wafers need to be separated, so different types of interlayers are required. The materials for the interlayer include corrugated board, sulfuric acid paper, and pearl cotton. Silicon wafers can only be in contact with sulfuric acid paper. , so three different interlayers are required, including corrugated board, pearl cotton, sulfuric acid paper from top to bottom, sulfuric acid paper, pearl cotton, sulfuric acid paper, sulfuric acid paper, pearl cotton, corrugated board, manual configuration is time-consuming and laborious, so the design is as follows figure 1 The silicon wafer interlayer configuration mechanism shown includes a frame 1, an auxiliary material lifting device 2, a material preparation rotary manipulator 3, an interlayer material preparation turntable 4, a sulfuric acid paper batching table 5, a lifter 6, a pearl cotton feeding rotary platform 7, and auxiliary materials Lifting device ...

Embodiment 2

[0041] As shown in Embodiment 1, a silicon chip interlayer configuration mechanism differs only in that two guide pillars 66 are fixed inside the outer frame 61, and the guide pillars 66 are respectively fixed on both sides of the synchronous belt 64, and the lifting plate 65 Linear bearings 67 are respectively installed on both sides of the two sides, and the linear bearings 67 are slidably installed on the guide post 66 . By setting the guide post 66 and the linear bearing 67, it is ensured that the lifting plate 65 remains stable during the lifting process.

Embodiment 3

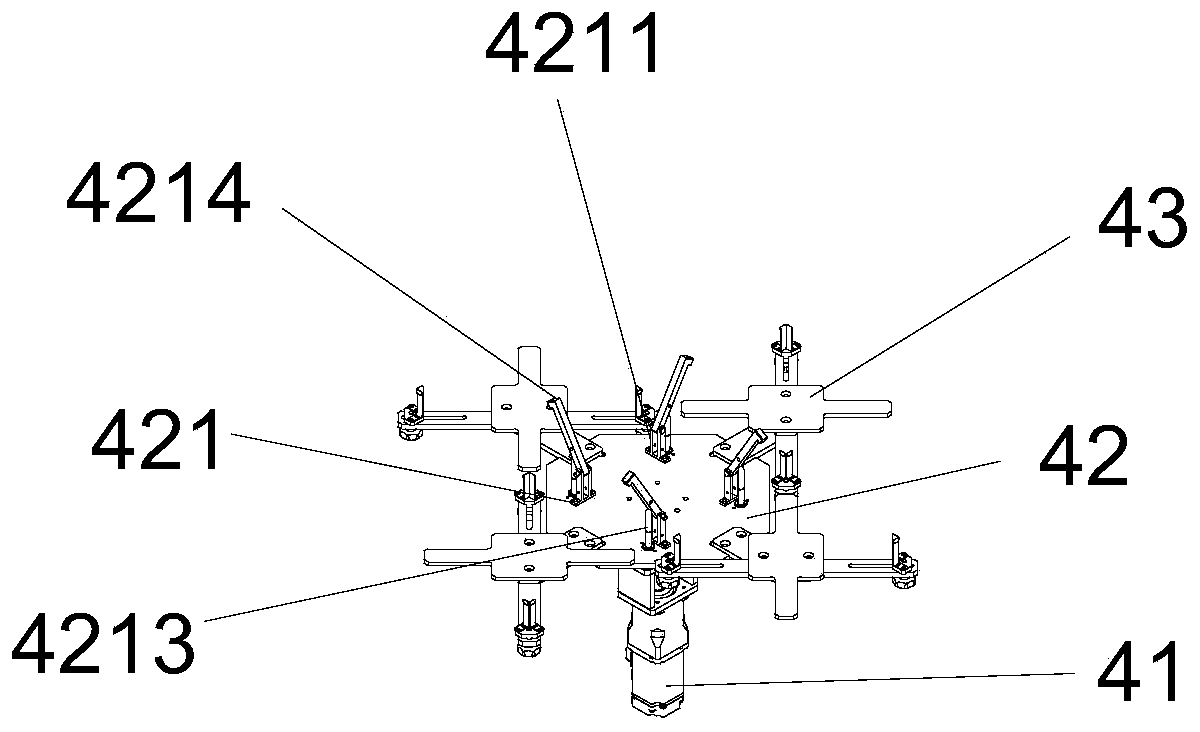

[0043] A kind of silicon wafer interlayer configuration mechanism as shown in embodiment 1, its difference is only, also be provided with a pressing mechanism 421 on one side of each adjusting frame 43, and pressing mechanism 421 is installed on the rotary table 42, presses The tightening mechanism 421 is used to compress the arranged interlayer to ensure that after the interlayer is arranged, the interlayer will not float away during the rotation of the turntable.

[0044] The pressing mechanism 421 is made up of a jacking frame 4211, a jacking cylinder 4212, a jacking guide post 4213, and a pressing plate 4214. One end of the jacking frame 4211 is fixed on the table top of the rotary table 42, and one end of the pressing plate 4214 is rotatably mounted on the top of the jacking frame 4211. At the other end, one end of the lifting guide post 4213 passes through the turntable 42 and is fixed on the pressure plate 4214 , and the other end of the lifting guide post 4213 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com