A non-woven fabric branching and cutting device for diaper production

A cutting device and technology of non-woven fabrics, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems such as difficult to adjust its width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

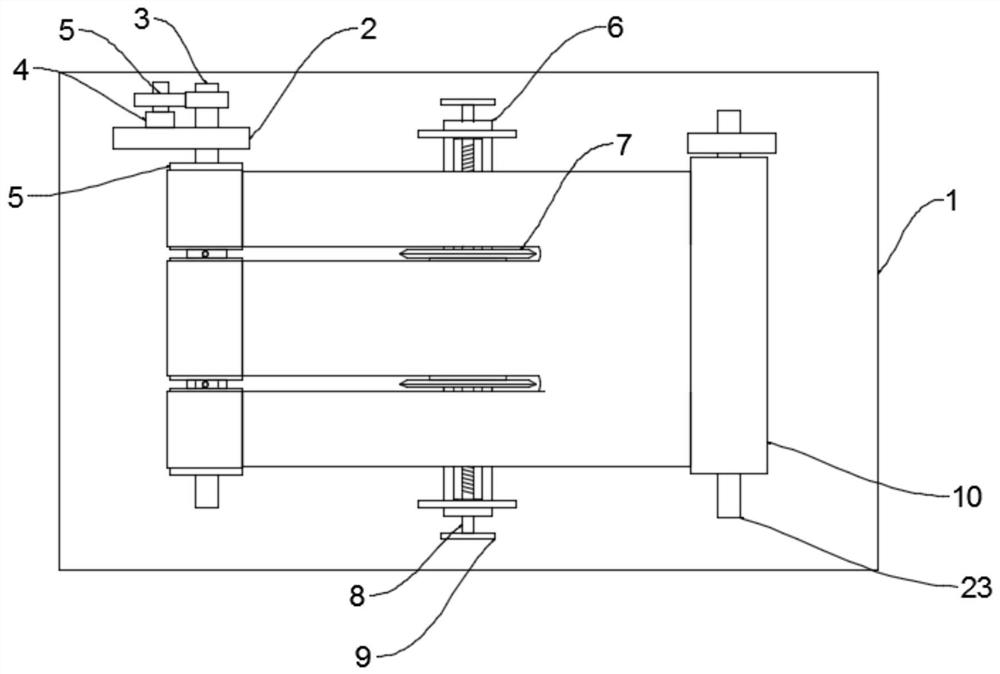

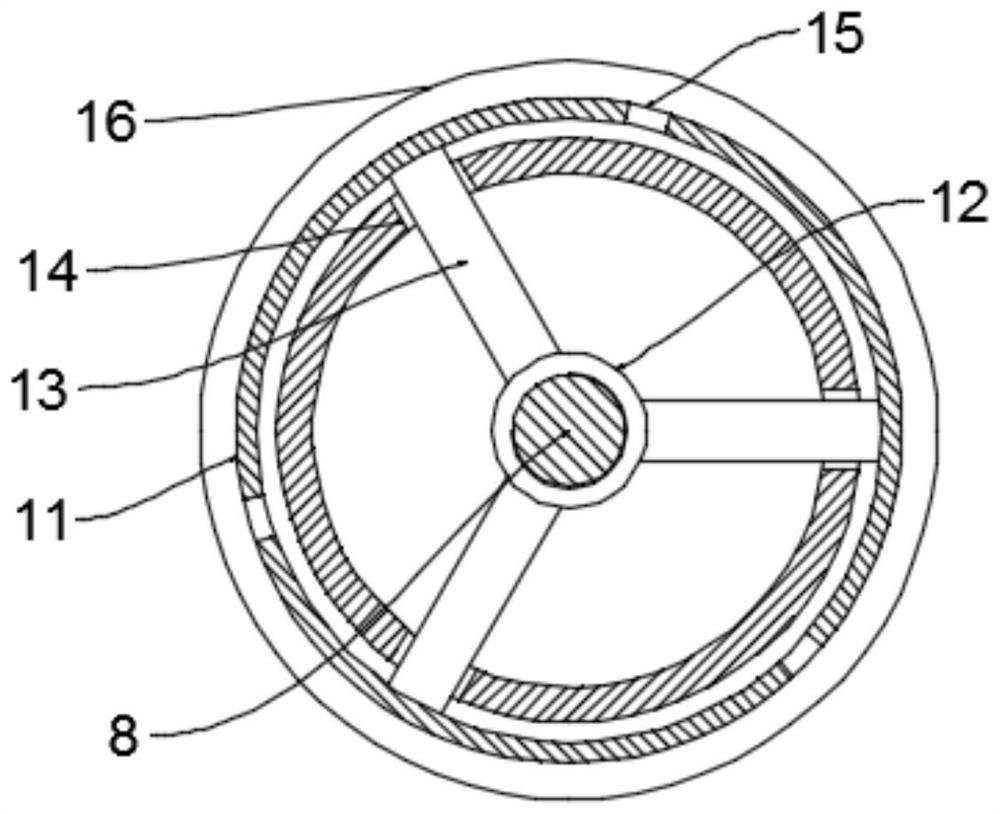

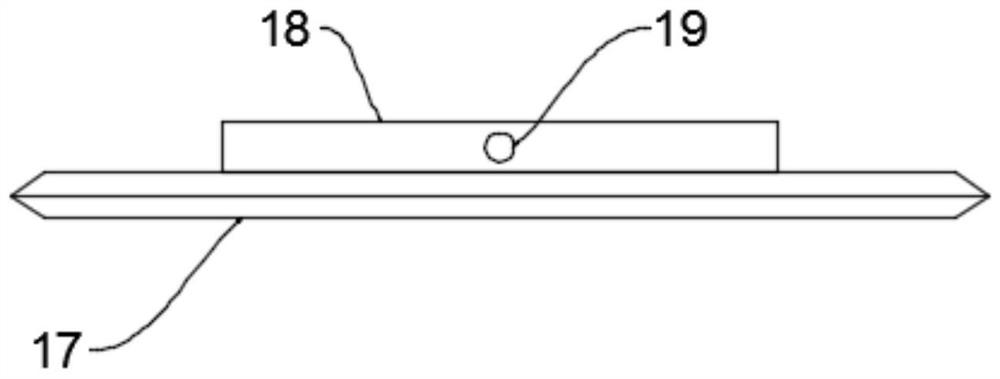

[0022] see Figure 1~3 , in an embodiment of the present invention, a non-woven fabric branching and cutting device for diaper production, including a platen 1, three mounting frames 2 are arranged on the platen 1, and three mounting frames 2 are respectively provided with mounting Rod shaft 23, regulating pipe body 6 and rewinding rod shaft 3, the rewinding rod shaft 3 is installed on the mounting frame body 2 in the middle, and the rewinding rod shaft 3 and the mounting rod shaft 23 are all installed on the mounting frames on both sides On the body 2, an unwinding roller 10 for unwinding non-woven fabrics is installed on the installation rod shaft 23, and three winding rollers 5 and three winding rollers 5 are installed on the winding rod shaft 3. Linear and equidistant distribution, the mounting frame body 2 is provided with a power unit that can drive the winding rod shaft 3 to rotate, and the power unit package is a winding motor 4 arranged on the mounting frame body 2, a...

Embodiment 2

[0026] see Figure 4 The difference between this embodiment of the present invention and Embodiment 1 is that: the winding roller 5 is detachably mounted on the winding rod shaft 3, specifically, one end of the winding roller 5 is provided with an end groove 20 and the width of the end groove 20 is greater than the diameter of the winding rod shaft 3, and the other end of the winding roller 5 is fixed with a connecting protrusion 21 whose section can be plugged into the inside of the end groove 20, and the connecting protrusion 21 is provided with a fixing screw hole 22, The length of the connecting protrusion 21 is greater than the depth of the end groove 20, and then the connecting protrusion 21 is inserted into the inner side of the end groove 20 on the other winding drum 5 and the fixing screw hole 22 is exposed on the outside, and then fixed by screws, This is convenient for uniform fixing and can ensure that the distance between the joints of the winding rollers 5 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com