Bidirectional multi-piston hybrid magneto-rheological shock absorber

A magnetorheological shock absorber and hybrid technology, applied in the field of magnetorheological, can solve the problems of restricting the application range of the magnetorheological shock absorber, small adjustable range of damping force, affecting the performance of the shock absorber, etc. Magnetic shielding performance, improve damping force, improve the effect of working displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

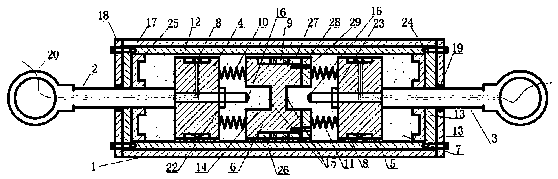

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] like figure 1 As shown, the two-way multi-piston hybrid magnetorheological shock absorber includes working cylinder 1, piston rod I2, piston rod II3, electromagnetic piston I4, electromagnetic piston II5, floating piston 6, magnetorheological fluid 7, coil 8. Permanent magnet ring 9, spring I10, spring II11;

[0028] The electromagnetic piston I4, the floating piston 6, and the electromagnetic piston II5 are sequentially arranged in the working cylinder 1 according to the direction from left to right, and the working cylinder 1 is filled with magnetorheological fluid 7;

[0029] The electromagnetic piston I4 is fixedly connected with the piston rod I2, and the front end of the piston rod I2 extends out of the working cylinder 1 from the left end of the working cylinder 1; the electromagnetic piston II5 is fixedly connected with the piston rod II3, and the The front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com