Underwater hose safe disengaging device

A disengagement device and safe technology, applied in the direction of hose connection device, fluid pressure actuating device, fluid pressure actuating system safety, etc., can solve the problems of high risk, difficult operation, damage of water surface support system, etc., to achieve stable and reliable The effect of snapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

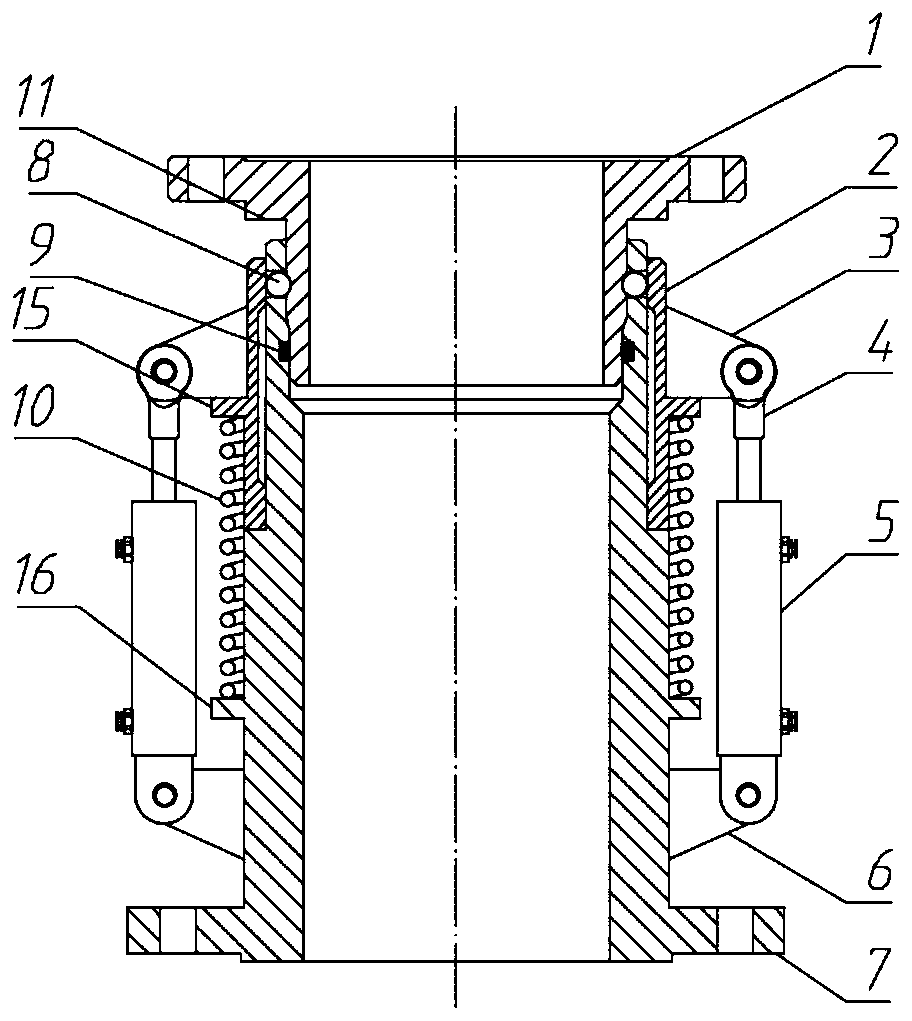

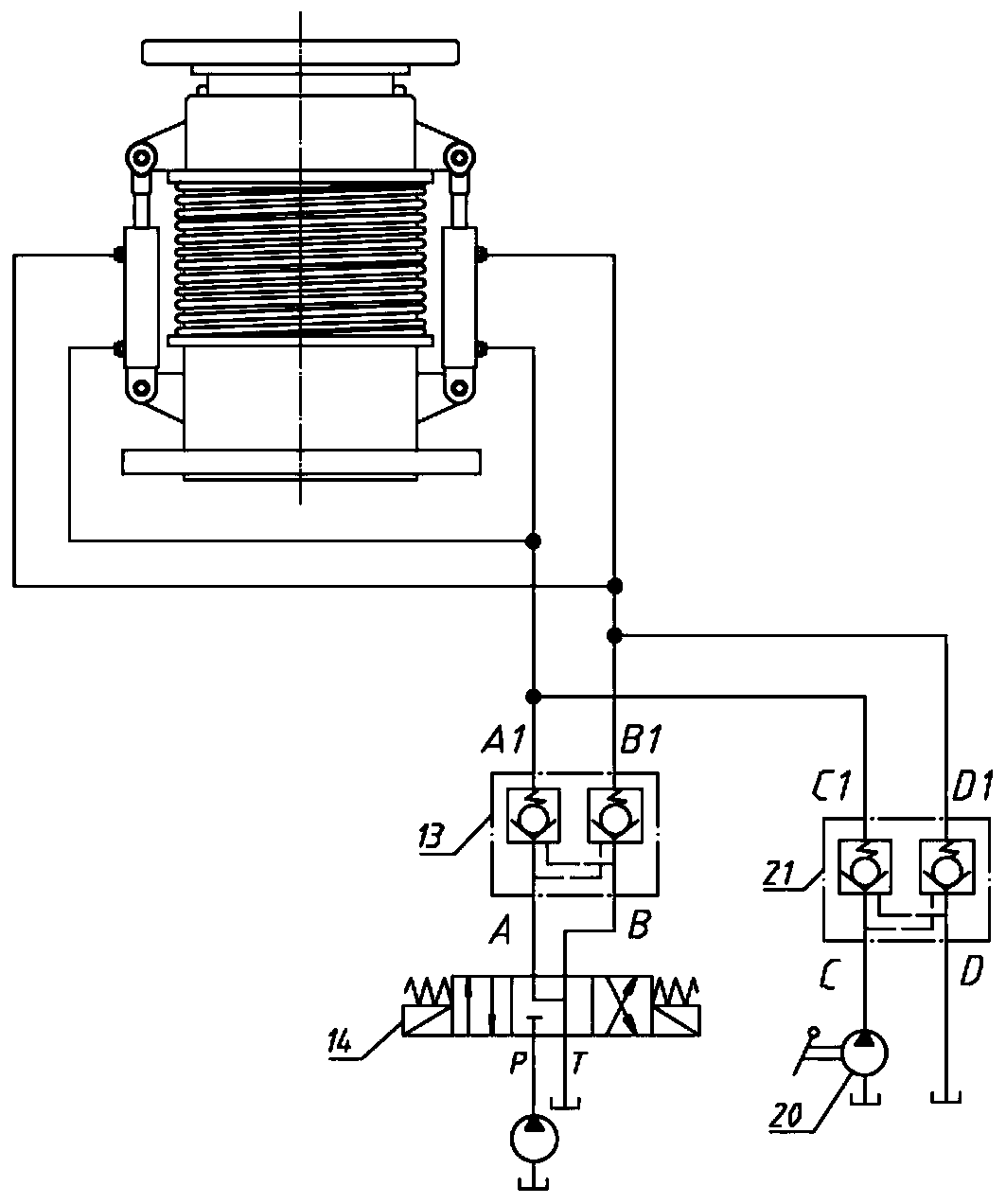

[0030] Such as Figure 1 to Figure 2 As shown, an underwater hose safety disconnection device includes a male joint 1, a slip ring 2, a first support 3, an earring 4, an oil cylinder 5, a second support 6, a female joint 7, a steel ball 8, and a seal 9. Compression elastic member 10 and linear drive device 12;

[0031] The male joint 1 and the female joint 7 are hollow cylinders;

[0032] One end of the male connector 1 is a flange structure, which is connected to the flange of the hose;

[0033] A stepped surface 11 is provided on the outer wall of the male joint 1 close to the flange mounting surface;

[0034] The other end of the male connector 1 is sleeved in the central hole of the female connector 7;

[0035] The other end of the female joint 7 is a flange structure, which is connected with the flange interface of the working equipment;

[0036] The material in the hose enters the operating equipment through the central holes of the male joint 1 and the female joint ...

Embodiment 2

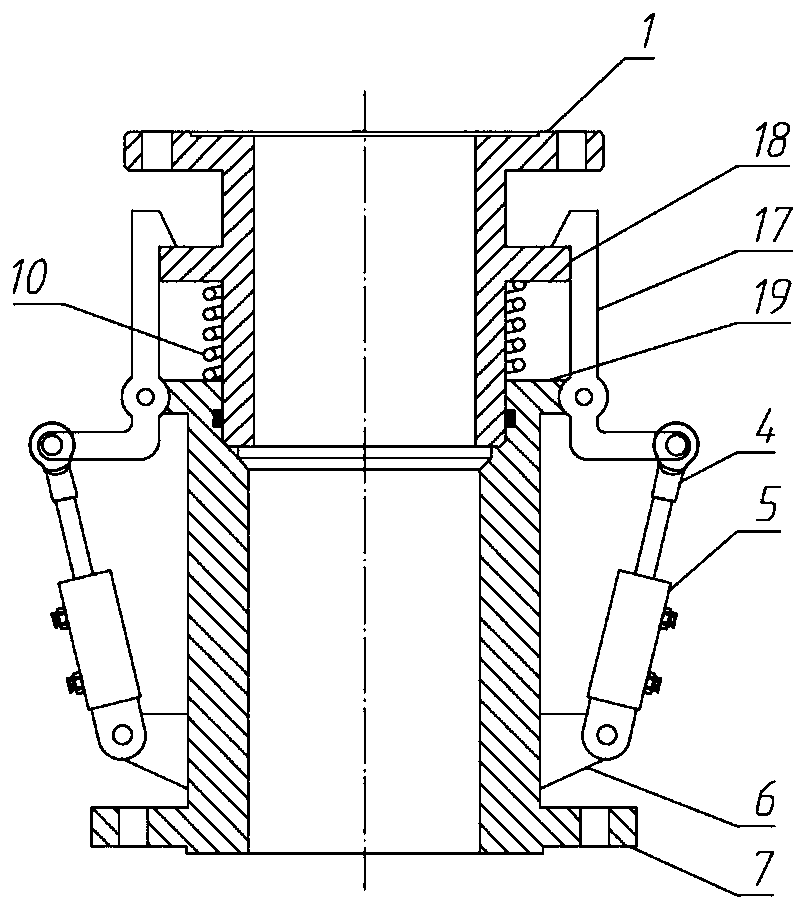

[0064] Such as Figure 3 to Figure 4 As shown, in this embodiment, claws are used to securely clamp the male joint 1 and the female joint 7 .

[0065] Specifically, an underwater hose safety detachment device, including a male joint 1, a female joint 7, a sealing member 9, a compression elastic member 10, a swing arm 17 and a linear drive device 12;

[0066] The outer wall of the male joint 1 is provided with a third step 18;

[0067] The end of the female joint 7 opposite to the flange is provided with a fourth step 19;

[0068] Several swing arms 17 are arranged circumferentially along the outer wall of the female joint 7;

[0069] The swing arm 17 is an L-shaped flat plate, and its middle position is hinged with the fourth step 19;

[0070] The upper end of the swing arm 17 is provided with a claw, and the claw hooks the upper surface of the third step 18;

[0071] The lower end of the swing arm 17 is bent outward at 90 degrees, and its end is hinged to the movement ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com