Variable-volume phase-change heat storage water tank

A phase change heat storage and volume technology, which is used in heat storage equipment, heat storage heaters, fluid heaters, etc. and site requirements to facilitate, prolong heating time, reduce the effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

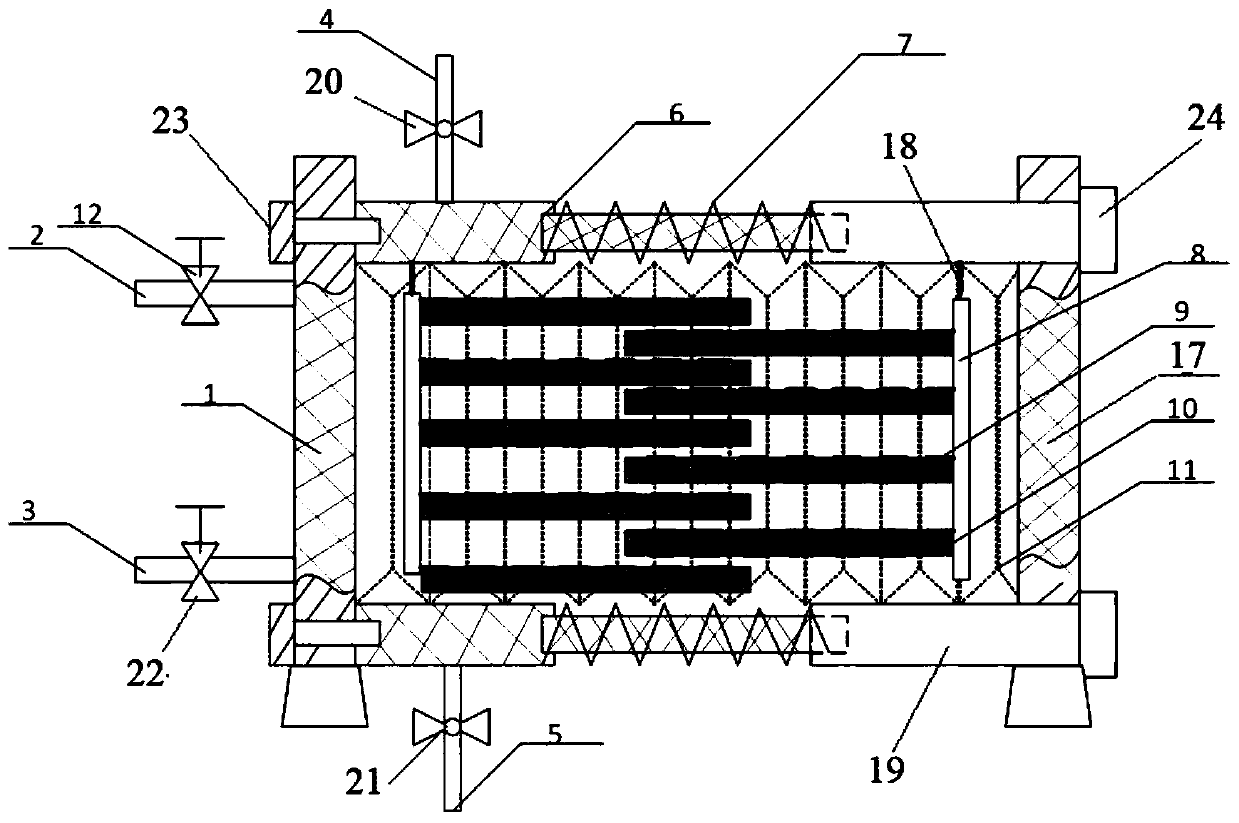

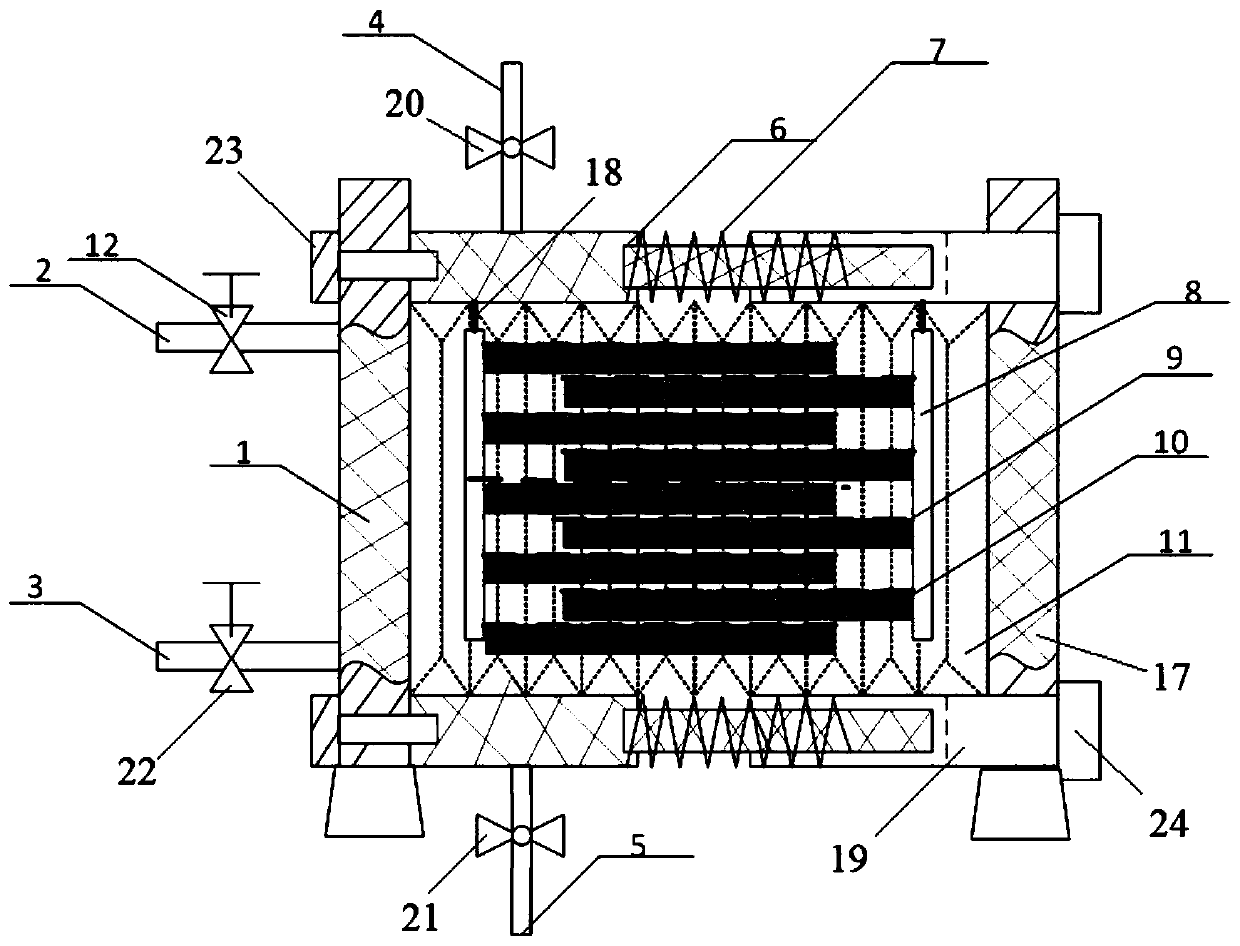

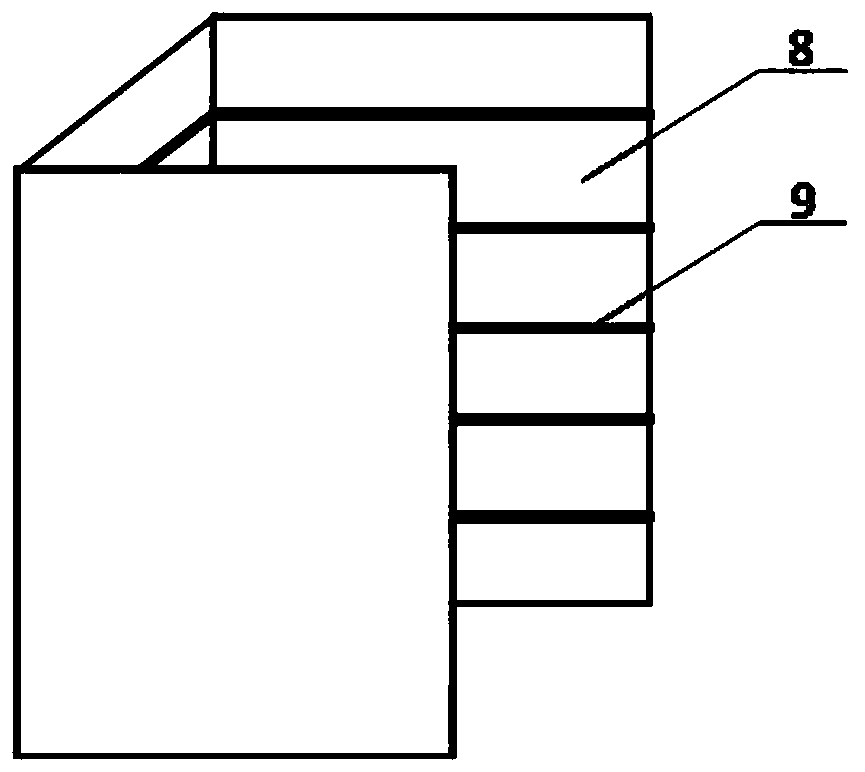

[0031] Such as Figures 1 to 5 As shown, the variable volume phase-change hot water storage tank of the present invention includes a telescopic cavity, and the telescopic cavity is surrounded by the first vertical plate 1, the second vertical plate 17, the top telescopic plate 6 and the bottom telescopic plate 19 rectangular cavity. Both the first vertical board 1 and the second vertical board 17 are provided with a base at the bottom, and the first vertical board 1 can move horizontally relative to the second vertical board 17, approaching or moving away.

[0032] Both the top telescopic board 6 and the bottom telescopic board 19 are composed of a first connecting board, a sliding bar and a second connecting board that are nested together and can slide with each other. One side of the first connecting board is connected to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com