Test piece and test contactor comprising same

A technology of test piece and contact surface, which is applied in the direction of semiconductor/solid-state device testing/measurement, contact parts, connection, etc., can solve the problem of contact failure between test piece and product pin, achieve simple structure, low cost, and improve pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

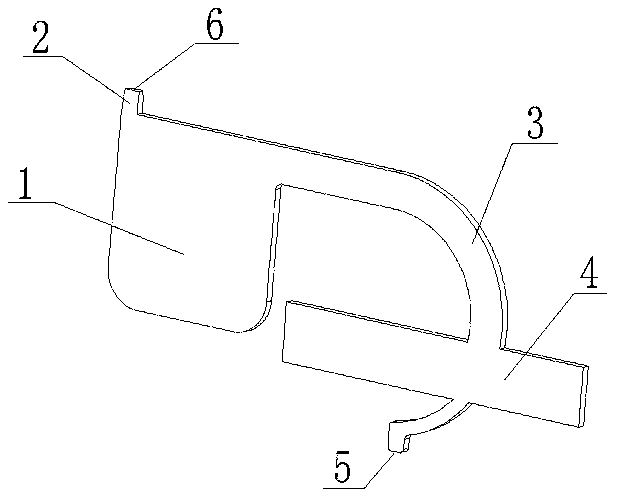

[0018] A test piece, the test piece includes a guide body 1, a test piece head 2, an arc-shaped elastic region 3, a mounting bracket 4 and a test board contact surface 5, the guide body 1 and the test piece head 2 arranged above the guide body 1 ; The guide body is provided with an arc-shaped elastic area 3, the arc-shaped elastic area 3 is provided with a mounting bracket 4, and the mounting bracket is provided with a test board contact surface 5.

[0019] The test piece of the present invention is used to contact with the product pin and press down to make the arc elastic zone of the test piece produce deformation for testing. The test contact surface on the test chip head is in contact with the pins, thus greatly reducing the problem of contact failure between the test chip and the product pins, thereby improving the accuracy of product test results and improving the pass rate of products.

Embodiment 2

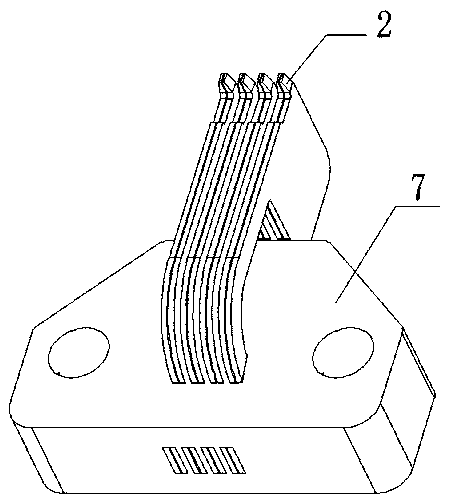

[0021] Such as figure 2 As shown, the test contactor of the present invention includes a test contact piece substrate 7 on which at least one test piece as described in Embodiment 1 is provided. The mounting bracket 4 of the test piece is fixed on the test contact piece substrate 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com