Composite diaphragm for lithium-sulfur battery and preparation and application thereof

A composite diaphragm, lithium-sulfur battery technology, applied in battery pack parts, circuits, electrical components, etc., to improve cycle performance, reduce ion transmission resistance, and inhibit the shuttle effect.

Inactive Publication Date: 2020-04-07

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Purpose of the invention: the main purpose of the invention is to solve the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

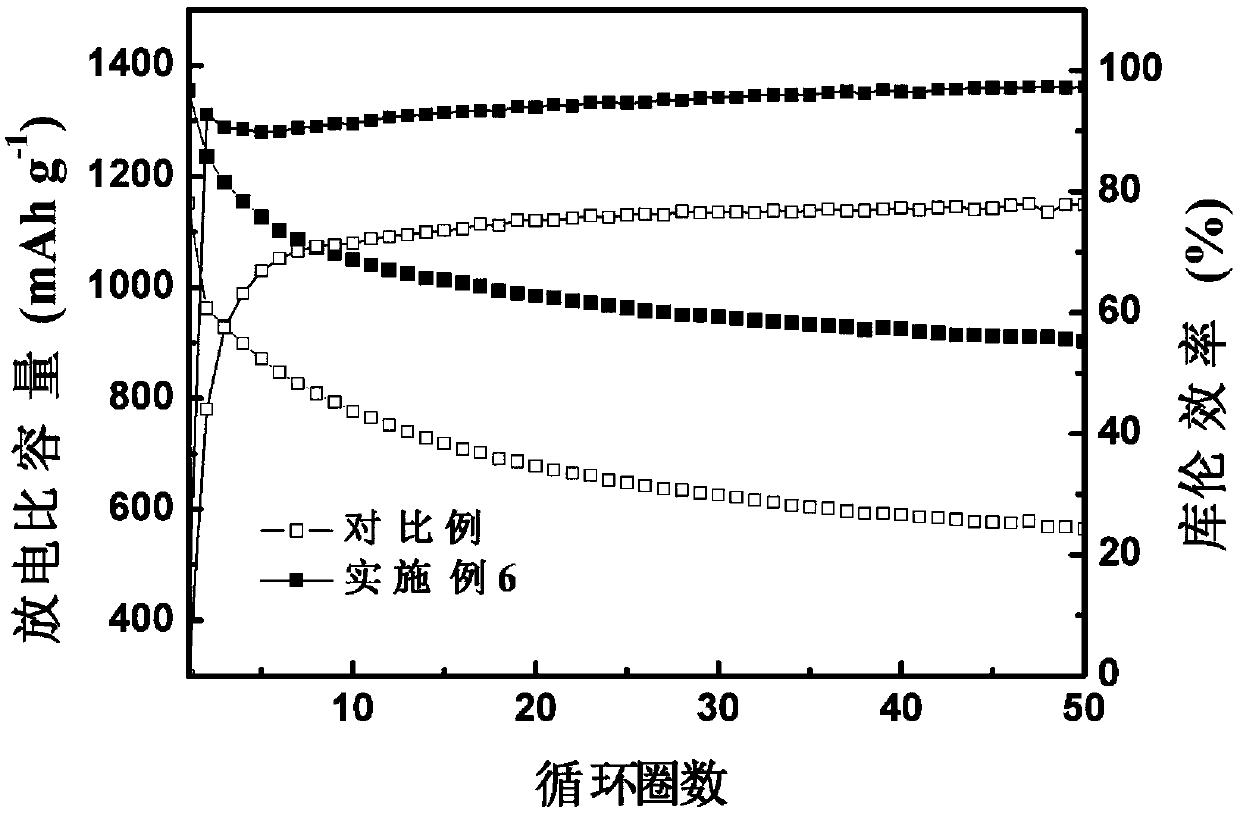

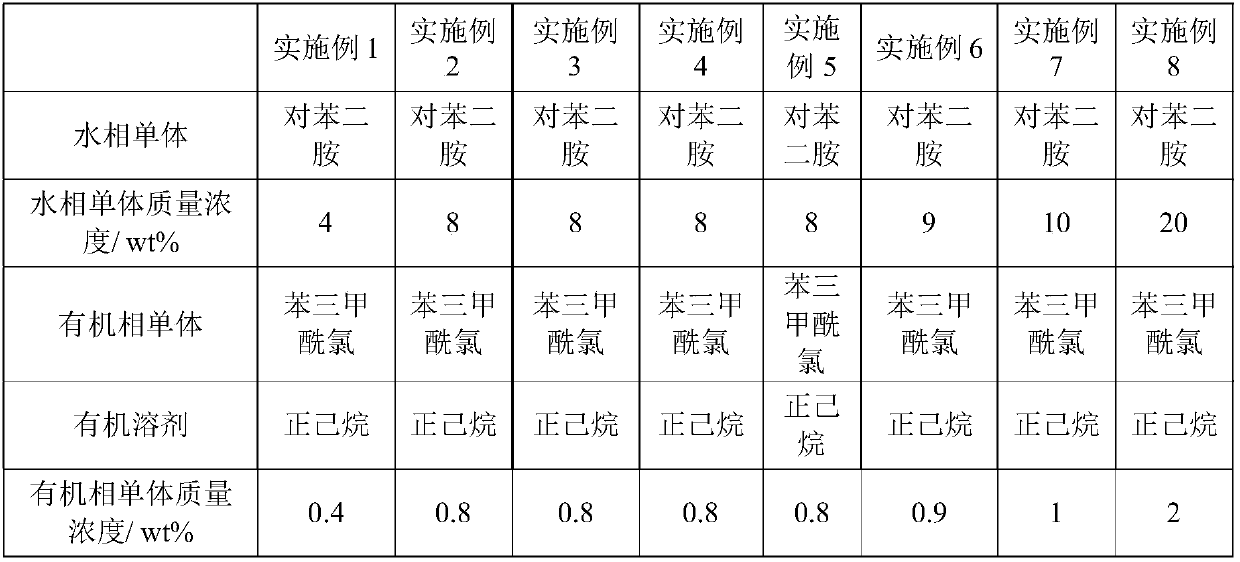

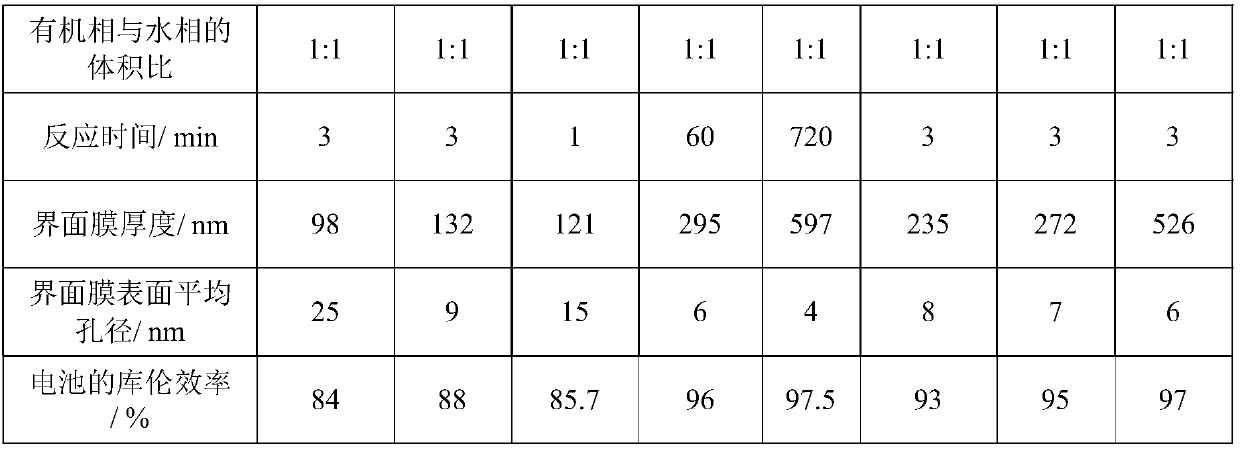

The invention discloses a composite diaphragm with an ultrathin coating and a preparation method and application thereof. A layer of interface film is generated through polymerization reaction of twomonomers on an oil-water interface, and then the interface film is transferred to a porous polyolefin diaphragm to form the composite diaphragm. The thickness and the surface aperture of the interfacefilm can be effectively controlled, and the formed composite diaphragm can effectively inhibit the shuttle flying effect of polysulfide and has higher mechanical strength; in addition, the method issimple in preparation process, low in time consumption, low in cost and beneficial to further popularization and application.

Description

technical field [0001] The invention relates to the field of lithium-sulfur batteries, in particular to a composite diaphragm and its preparation method and application. Background technique [0002] In order to solve the energy crisis and the environmental pollution caused by the combustion of fossil fuels, electric vehicles have received more and more attention. At present, lithium-ion batteries with lithium iron phosphate and ternary materials as positive electrodes are widely used in electric vehicles. Due to the limitation of material properties, lithium-ion batteries have a theoretical specific capacity of 300mAh / g, which cannot meet the needs of long-range electric vehicles. The theoretical specific capacity of lithium-sulfur batteries is five times that of commercial lithium-ion batteries (theoretical specific capacity is 1672mAh / g, specific energy is 2600Wh / kg). It is considered to be one of the most potential high-energy batteries. [0003] However, the real comm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M2/14H01M2/16

CPCH01M50/403H01M50/411H01M50/449Y02E60/10

Inventor 李先锋李丹张华民

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com