Three-dimensional ordered porous sulfur-carrying material for positive pole piece of lithium-sulfur battery as well as preparation method and application of three-dimensional ordered porous sulfur-carrying material

A three-dimensional ordered, lithium-sulfur battery technology, applied in the field of electrochemical energy storage, can solve the problems of slow electrochemical reaction kinetics, low sulfur utilization rate, inability to lithium-sulfur batteries, etc., achieves low preparation cost, improved adsorption, The effect of large-scale commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

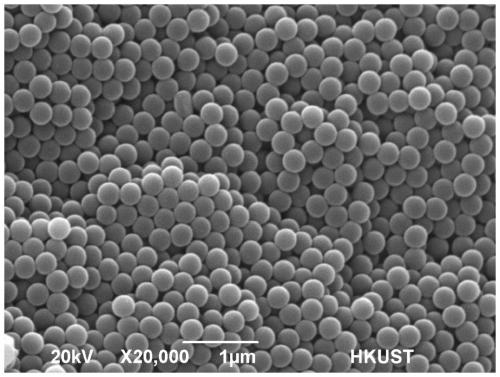

[0049] In this example, the specific preparation process of the three-dimensional ordered porous sulfur-carrying material is as follows:

[0050] (1) Preparation of polystyrene nanoparticles:

[0051] Take 70mL styrene solution, wash it once with 25mL 10wt.% sodium hydroxide solution to remove the stabilizer in the styrene solution, then wash the styrene solution three times with deionized water and collect it for later use.

[0052] Take 65 mL of the above-mentioned cleaned styrene solution and add it into 500 mL of deionized water to obtain a mixed solution. Add 2.5 g of polyvinylpyrrolidone to the mixed solution, stir and dissolve it thoroughly, and then continuously blow nitrogen into the above solution for 30 minutes at room temperature to remove oxygen in the liquid. After that, the temperature of the above solution was raised to 75° C. under airtight and nitrogen or argon protection. After the temperature was stabilized, 50 mL of a solution containing 1 g of potassium...

Embodiment 2

[0064] In this example, the preparation process of the lithium-sulfur battery positive pole piece is as follows:

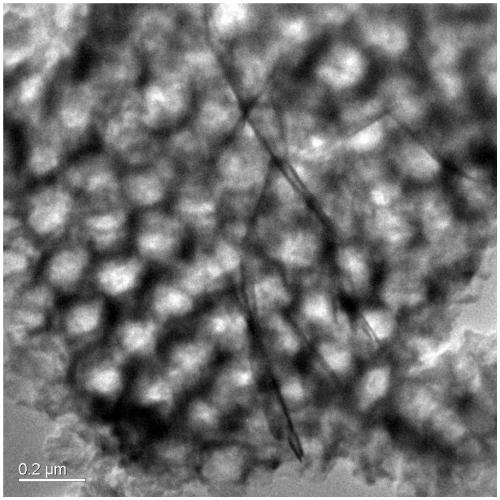

[0065] (1) The preparation method of carbon-sulfur complex, comprises the steps:

[0066] Take 0.1 g of the prepared three-dimensional ordered porous sulfur-carrying material and grind it fully with 0.3 g of sublimed sulfur in a mortar to obtain a uniform powder. The mixed solid powder was placed in an airtight container protected by argon, the temperature was raised to 155° C., and kept at this temperature for 12 hours. The resulting mixed powder is taken out as a carbon-sulfur compound.

[0067] (2) The preparation method of lithium-sulfur battery positive electrode slurry comprises the following steps:

[0068] Take 800mg of the carbon-sulfur complex obtained in (1) and place it in a glass bottle, add 100mg of conductive agent and 100mg of adhesive, add 3mL of N-methylpyrrolidone, stir thoroughly for 5 hours and sonicate to obtain a uniform suspension that is...

Embodiment 3

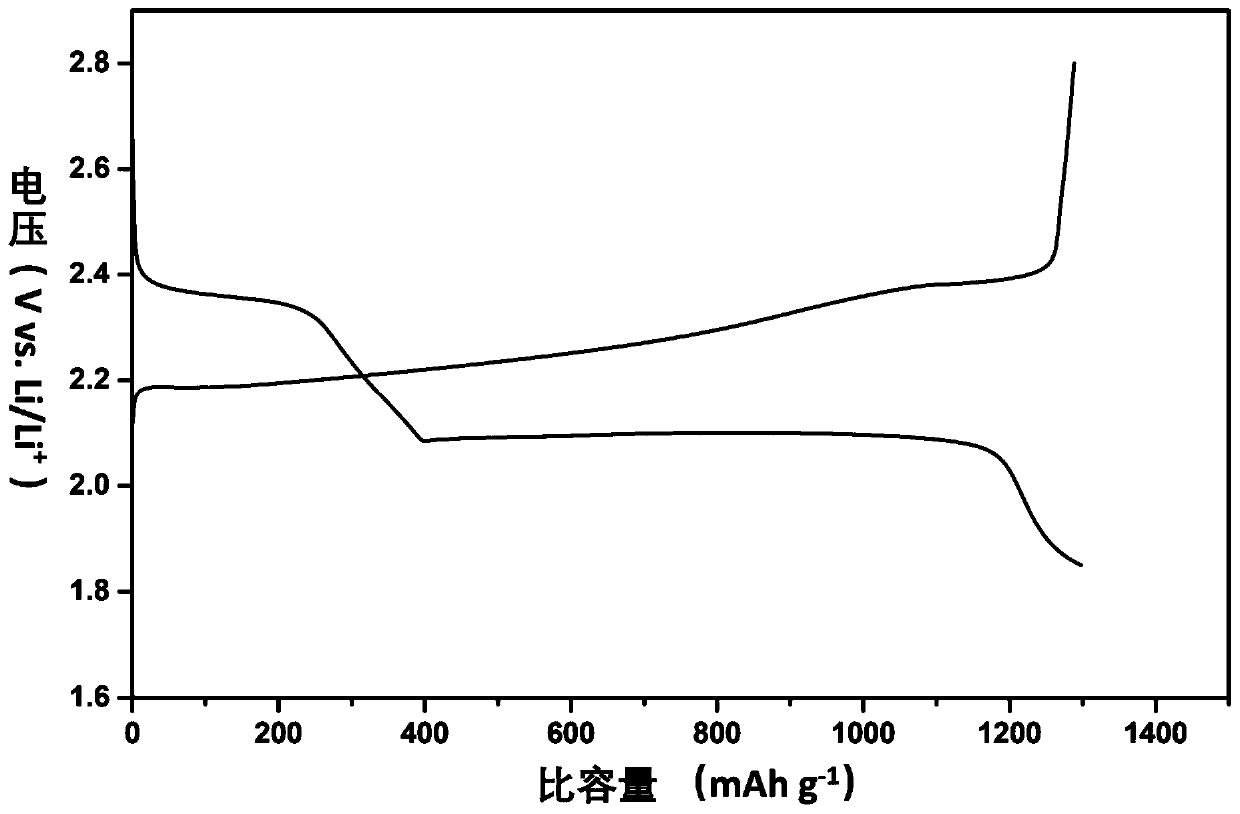

[0074] In this embodiment, the electrochemical test of the carbon-sulfur composite obtained after directly mixing the sublimated sulfur with the conductive agent as the positive electrode sheet includes the following steps:

[0075] (1) Preparation of carbon-sulfur complex

[0076] Take 100mg of Ketjen Black and 350mg of sublimated sulfur in a mortar, grind them thoroughly and add them into an airtight container protected by argon. The container was heated to 155°C and kept at this temperature for 12 hours to obtain a carbon-sulfur complex of Ketjen black and sublimated sulfur.

[0077] (2) Preparation of cathode slurry for lithium-sulfur battery

[0078] Take 800mg of the carbon-sulfur complex obtained in (1) in a glass bottle, add 100mg of conductive agent and 100mg of adhesive, add 3mL of N-methylpyrrolidone, stir thoroughly for 5 hours and sonicate to obtain a uniform suspension that is lithium Sulfur battery cathode slurry. Wherein, the conductive agent can be Ketjen b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Small hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com