Composite electrode material, preparation method thereof and all-solid-state lithium battery

A technology of composite electrodes and electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrochemical performance of all-solid-state lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The invention provides a kind of preparation method of composite electrode material, comprises the following steps:

[0072] A) mixing raw materials and electrode materials for synthesizing the sulfide electrolyte in a solvent, and reacting to obtain a reaction mixture, the chemical formula of the sulfide electrolyte is one or more of formulas (I) to (III);

[0073] aLi 2 S·(100-a-c)X b S n cY(I);

[0074] 03+ ,P 3+ ,P 5+ 、Si 4+ or Ge 4+ , Y is LiI, LiBr, Li 3 PO 4 , Li 4 SiO 4 ,P 2 o 5 、GeS 2 or P 2 S 3 ;

[0075] Li 10+a′ X' 1+a′ P 2-a′ S 12 (II);

[0076] X' is selected from one or more of the elements of the third, fourth or fifth main group;

[0077] 0≤a'≤1;

[0078] Li 4-a″ X″ 1-b′ Y' b′ S 4 (III);

[0079] X" is selected from one of Si and Ge, and Y' is selected from one of P, Al, Zn and Ga;

[0080] -1≤a″≤2, 0≤b′≤1;

[0081] B) the reaction mixture obtained in step A) is subjected to vacuum distillation to obtain a solid product;

...

Embodiment 1

[0099] In a glove box filled with argon atmosphere, first weigh 0.5g of cobalt sulfide according to the coating mass ratio of 15:85, and then weigh it according to Li 2 S and P 2 S 5 The molar ratio of substances is 7:3 and weigh 0.0287g of Li in turn 2 S and 0.0595g of P 2 S 5 . Add 20 mL of acetonitrile solvent. The raw material and the solvent are sealed in a quartz reaction bottle for reaction. Place the sealed reaction bottle on a magnetic heating stirrer and stir at 50° C. for 24 h at a stirring rate of 400 r / min.

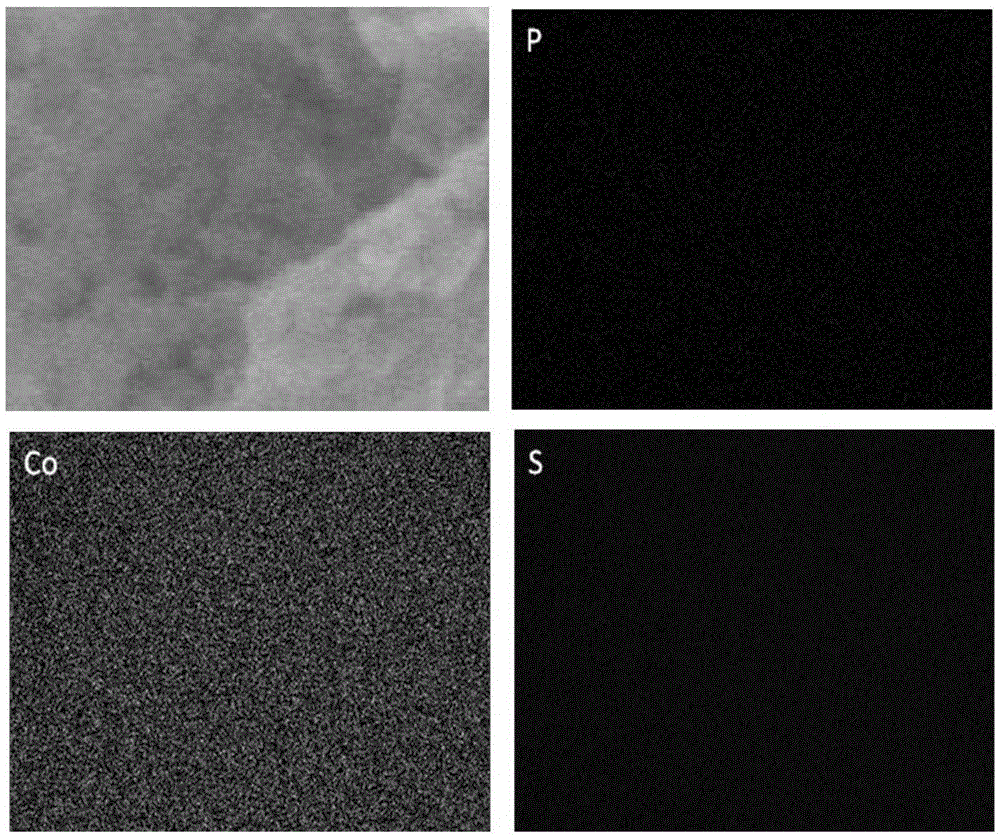

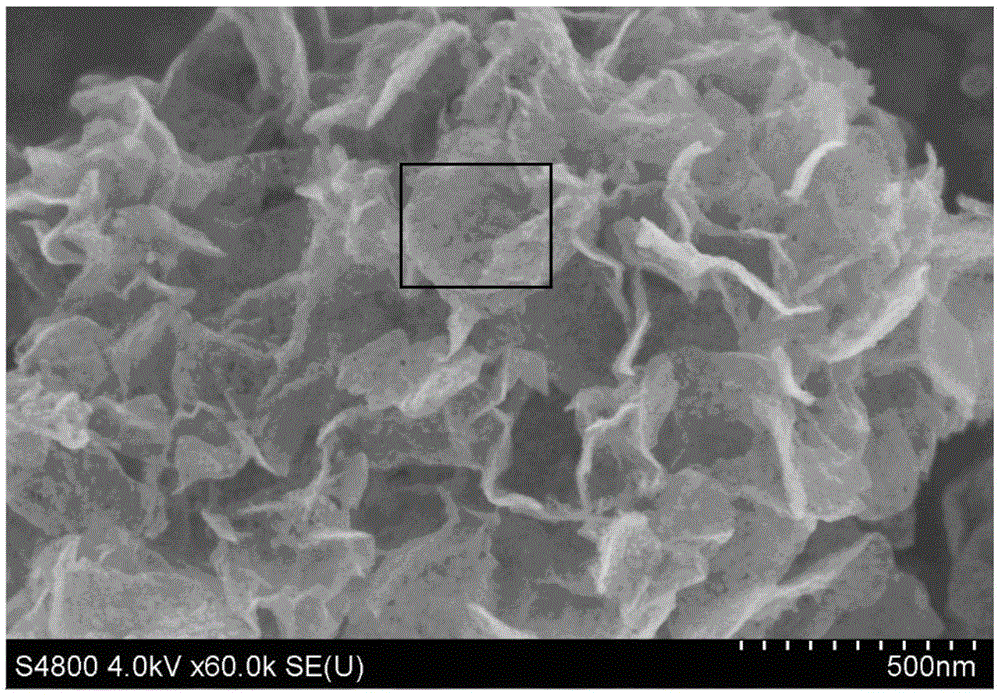

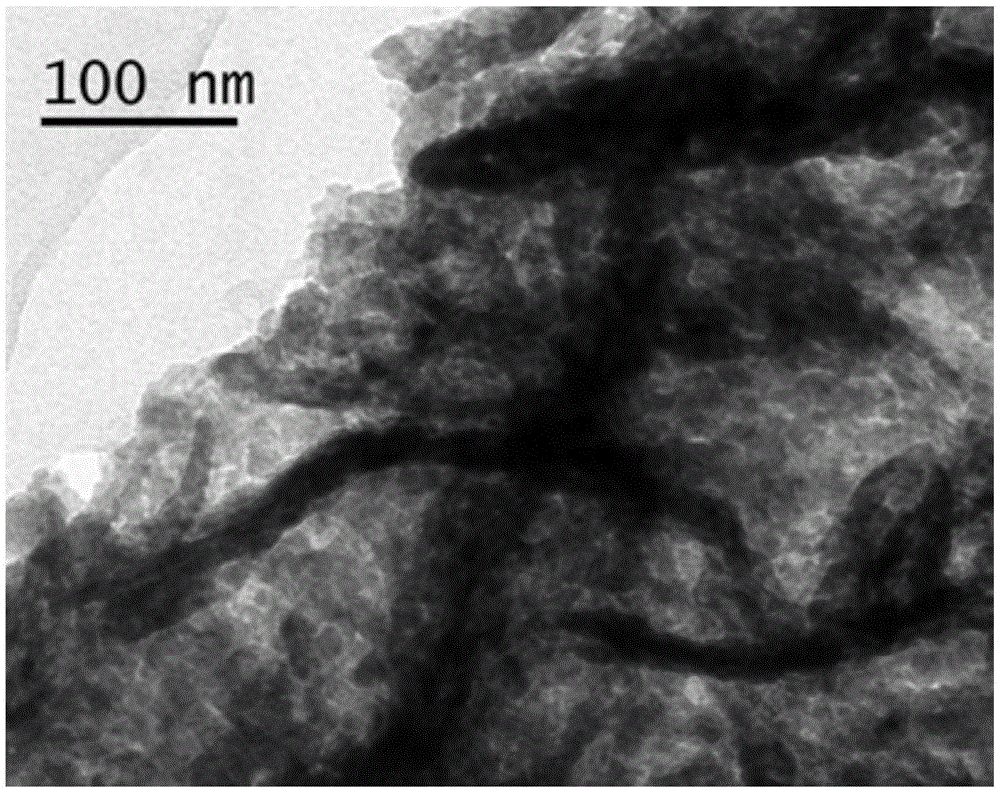

[0100] After the reaction, the solvent was distilled off under reduced pressure at 60° C. using a vacuum pump, and then dried in an oven at 80° C. for 12 hours. The dried composite electrode material was ground into powder with a mortar and transferred to Al 2 o 3 Finally, the crucible was placed in a muffle furnace and sintered in an argon atmosphere. The heating rate was 5°C / min, the sintering temperature was 260°C, and the sintering time was 1h. A...

Embodiment 2

[0105] In a glove box filled with argon atmosphere, first weigh 0.5g LiCoO according to the coating mass ratio of 15:85 2 , and then according to Li 2 S and P 2 S 5 The molar ratio of substances is 7:3 and weigh 0.0287g of Li in turn 2 S and 0.0595g of P 2 S 5 . Add 20 mL of acetonitrile solvent. The raw material and the solvent are sealed in a quartz reaction bottle for reaction. Place the sealed reaction bottle on a magnetic heating stirrer and stir at 50° C. for 24 h at a stirring rate of 400 r / min.

[0106] After the reaction, the solvent was distilled off under reduced pressure at 60° C. using a vacuum pump, and then dried in an oven at 80° C. for 12 hours. The dried composite electrode material was ground into powder with a mortar and transferred to Al 2 o 3 Finally, the crucible was placed in a muffle furnace for sintering under a nitrogen atmosphere, wherein the heating rate was 5°C / min, the sintering temperature was 260°C, and the sintering time was 1h. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com