Stator of outer rotor type wheel hub motor

A technology of in-wheel motor and outer rotor, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of limited motor installation space, unfavorable installation layout, and high winding ends, and achieves compact structure, easy mass production, slot The effect of increasing the full rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

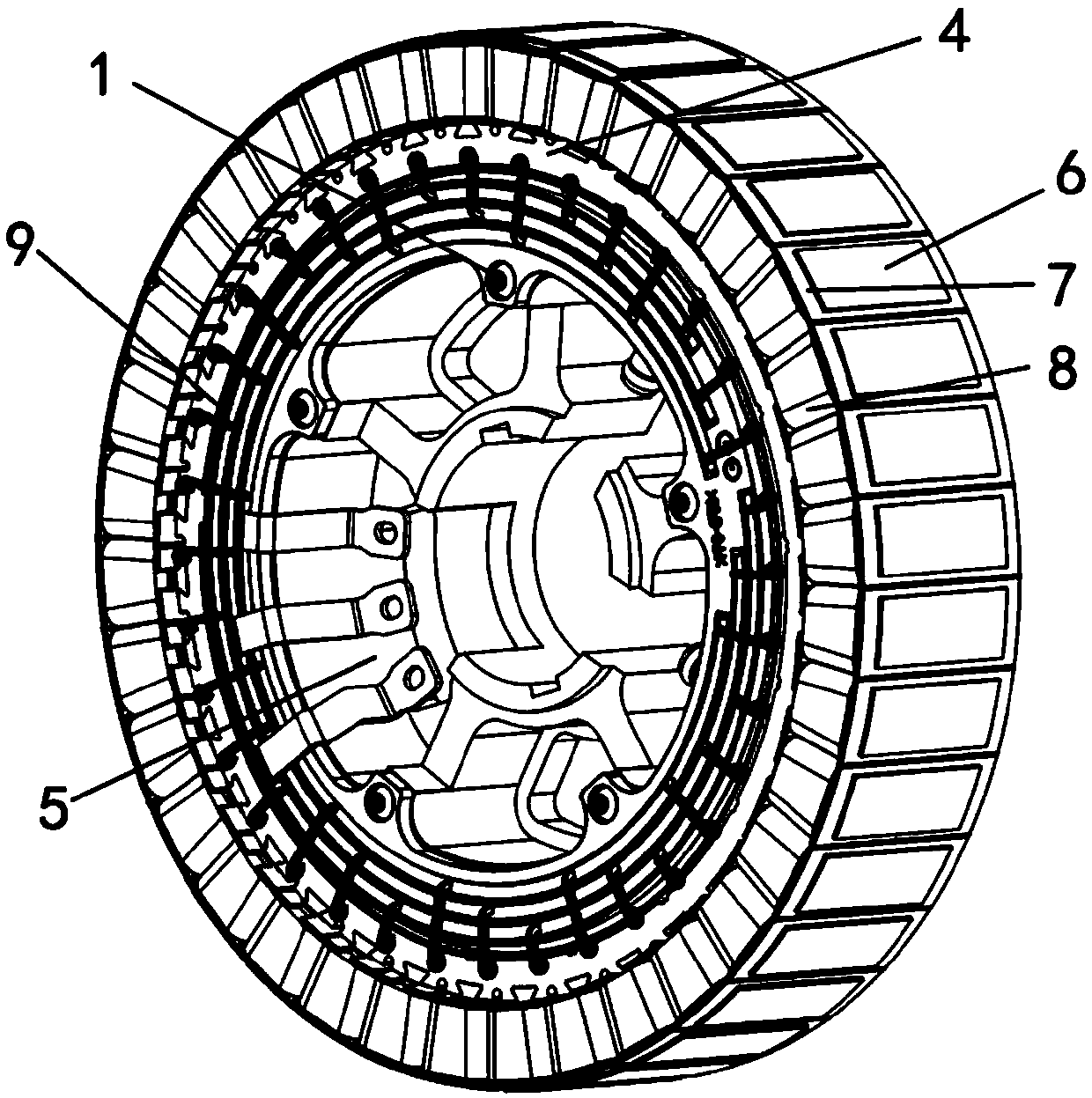

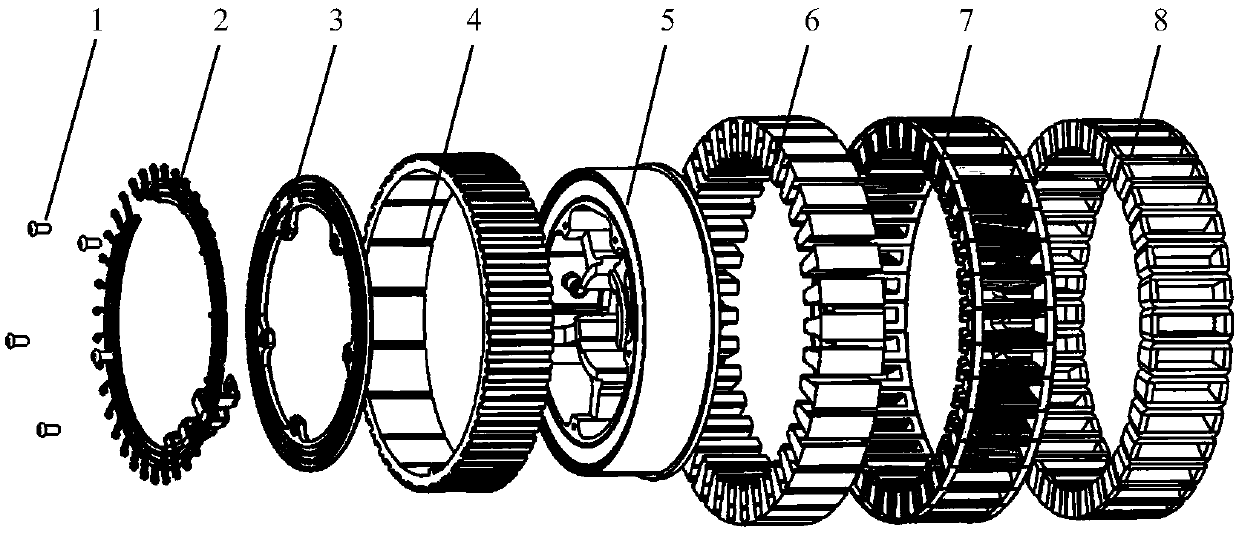

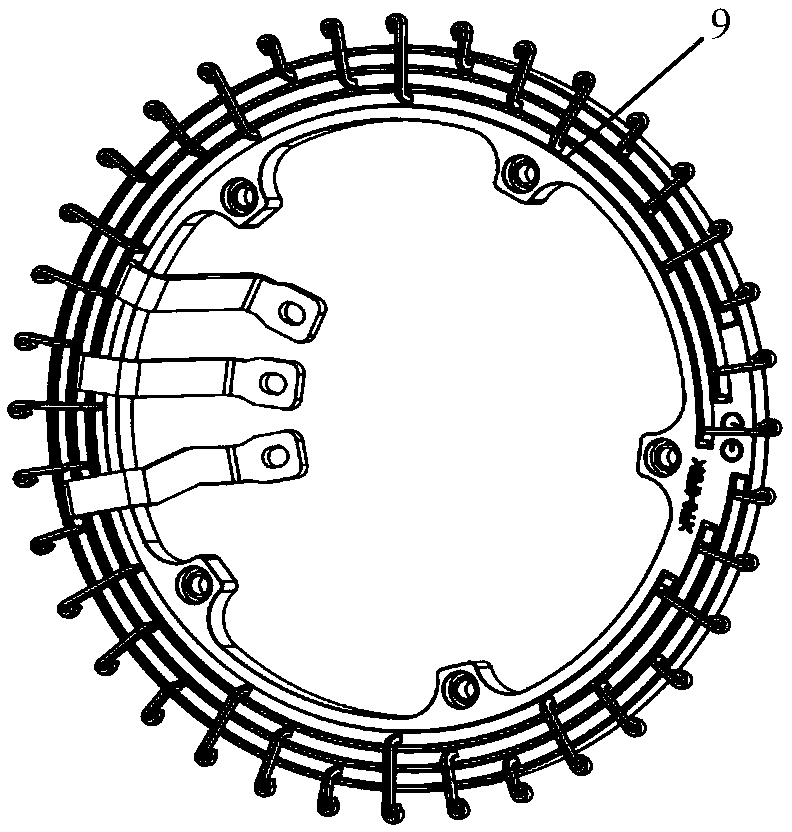

[0030] Such as figure 1 and figure 2 As shown, this embodiment provides a stator of an outer rotor type in-wheel motor, including a stator core, a stator support (5), an insulating frame (7), a stator coil (8) and a bus bar (9), and the stator core includes a stator The iron core yoke (4) and a plurality of stator iron core teeth (6), the stator iron core yoke (4) are fixed on the stator support (5) through interference. The stator core teeth (6) are evenly installed on the outer ring of the stator core yoke (4), each stator core tooth (6) is surrounded by an insulating frame (7), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com