A kind of negative pressure sealing packaging method

A packaging method and sealing packaging technology, which can be used in transportation and packaging, special packaging objects, packaging under vacuum/special atmosphere, etc. Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for negative pressure sealing packaging, comprising the steps of:

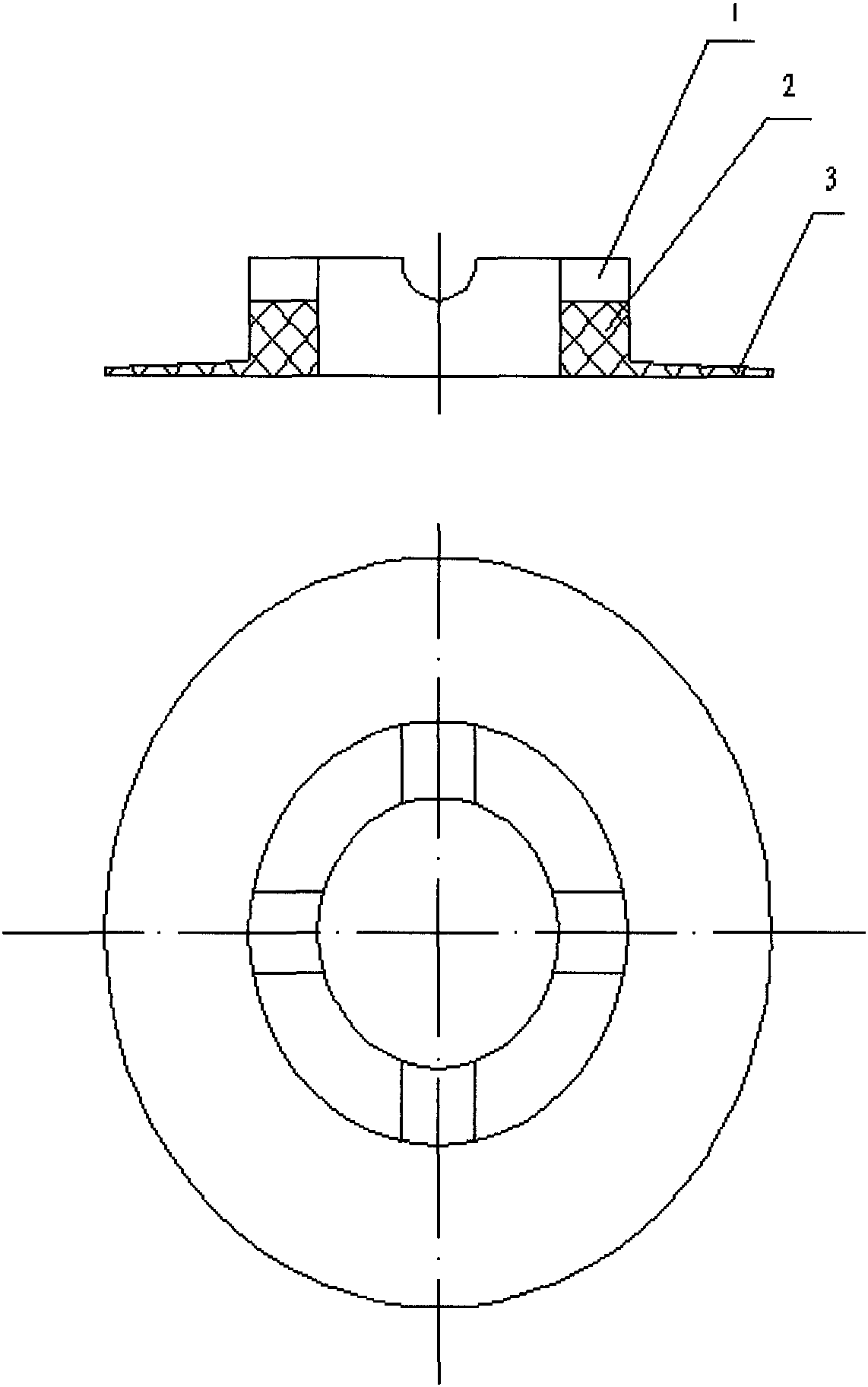

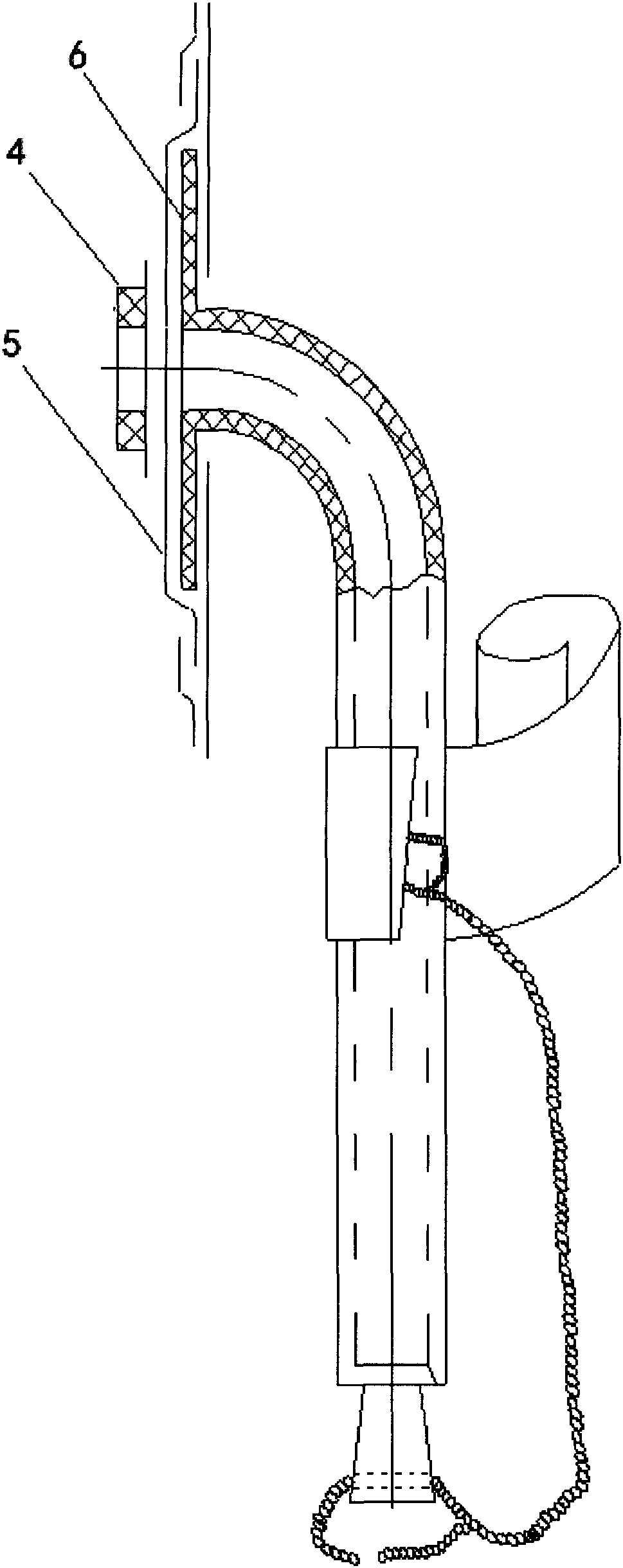

[0018] 1. Attach the outer edge of the air cushion to the interface 6 where the inner surface 5 of the sealed package is connected to the air extraction device, and conduct an air tightness test on the sealed package; the air cushion 4 is made of rubber as a raw material and manufactured through mold processing , consists of an outer edge 3 and a main body 2, the outer edge 3 is an annular sheet, the inner ring is connected to a hollow cylinder with a certain thickness, that is, the main body 2, and four pairs of opposite U-shaped grooves 1 are evenly distributed on the top of the main body. Such as figure 1 shown

[0019] 2. When pumping negative pressure, the pumping device is directly connected to the interface of the sealed package, and an air flow channel is established between the interface and the packaged object through the cushion, and the four grooves allow the surrounding gas to cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com