Liquid foundation and preparation method thereof

A liquid foundation and emollient technology, applied in the field of liquid foundation and its preparation, can solve problems such as color migration, achieve good absorption, maintain reproducibility, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

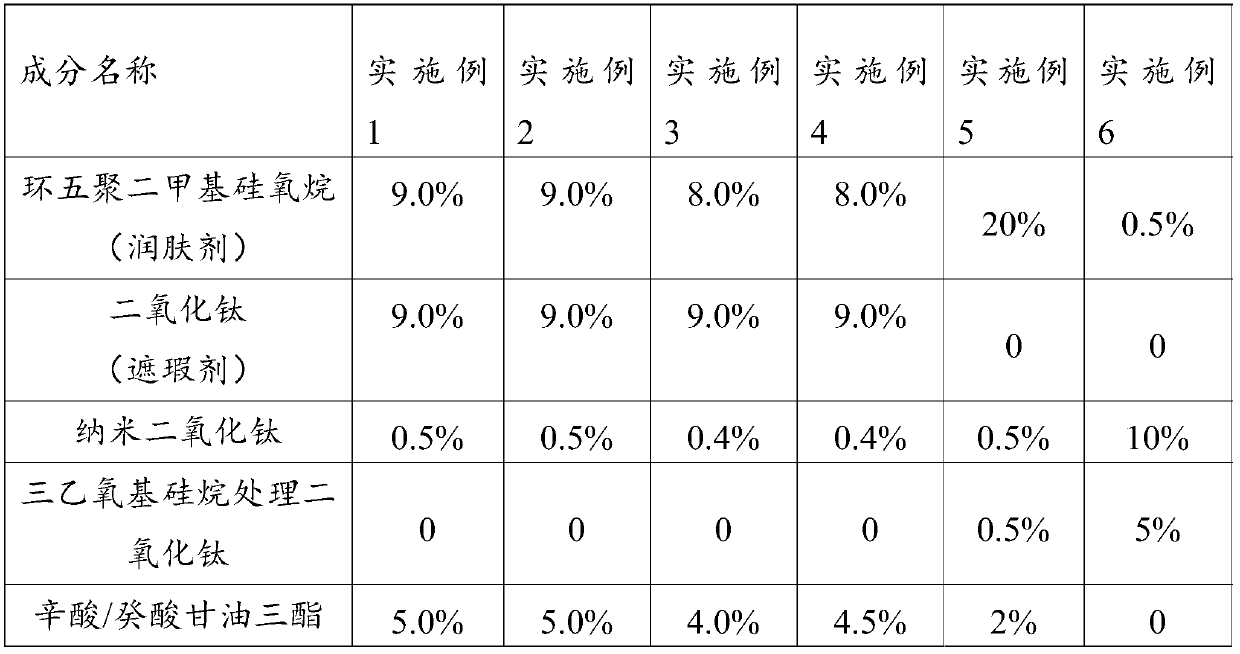

[0047]The preparation method of the liquid foundation described in above-mentioned embodiment 1, comprises the steps:

[0048] (1) Take each component according to the proportion; mix and stir the emollient, concealer, colorant and suspending agent to dissolve evenly, then add the concealer, and then use a colloid mill to grind the pigment for 3 times until the pigment is completely dispersed evenly, and put in the oil In the phase pot, add film-forming agent, emulsifier, emollient and suspending agent, heat to 80°C, keep stirring for 10 minutes to obtain the oil phase;

[0049] (2) Mix the solvent, humectant, emollient, suspending agent and preservative evenly, heat to 80°C, homogeneously disperse, keep warm and stir for 10 minutes, and obtain the water phase;

[0050] (3) Under the conditions of a stirring rate of 800rpm / min and a temperature of 80°C, drip the water phase described in step (2) into the oil phase described in step (1) at a rate of 2g / min, and then Homogenize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com