Electrostatic dust collection device based on non-uniform electric field

A technology of electrostatic dust collection and uniform electric field, applied in the field of dust removal, can solve the problems of secondary pollution of the environment, serious secondary pollution, high energy consumption of the device, and achieve the effects of avoiding secondary pollution, improving efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

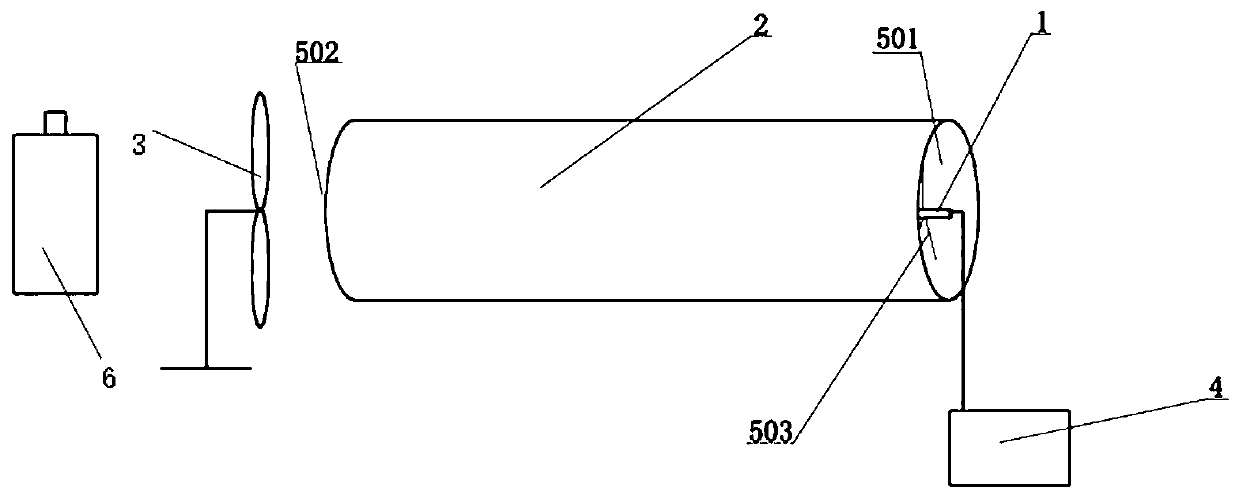

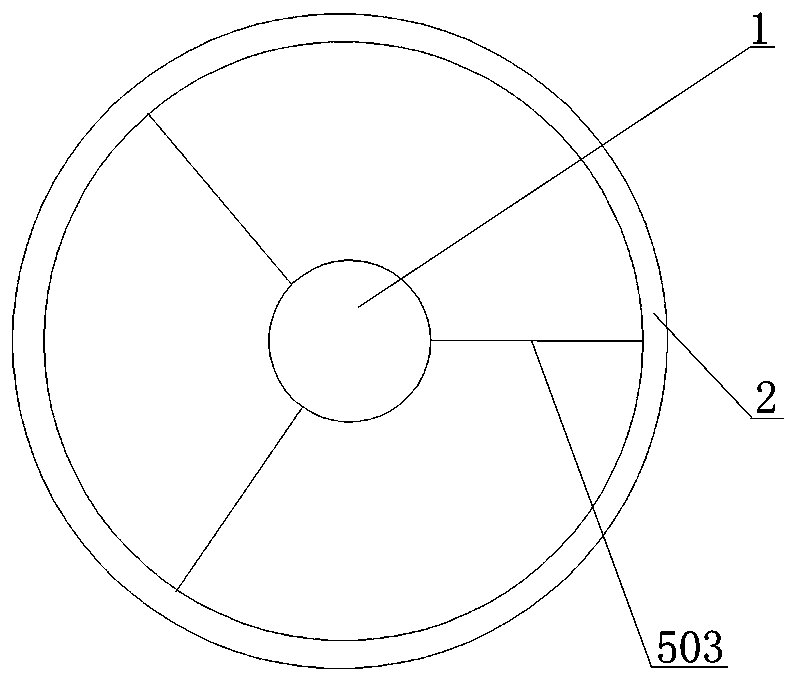

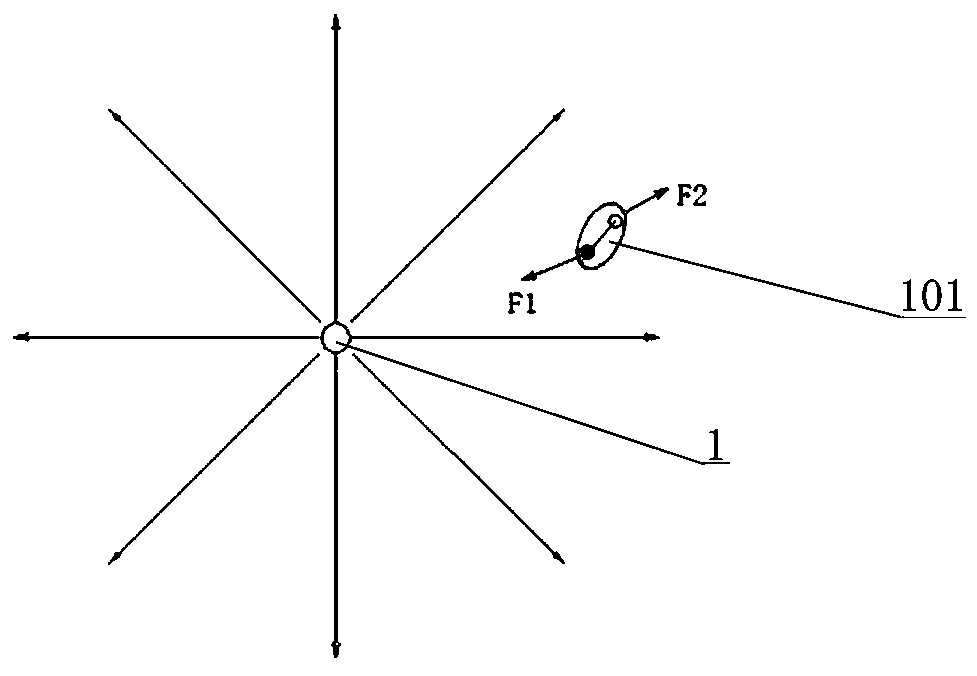

[0030] combine Figure 1 to Figure 4 , An electrostatic dust collecting device based on a non-uniform electric field, including a dust collecting electrode 1, a shielding pipe 2 and a fan 3, the shielding pipe 2 is coaxially sleeved on the outside of the dust collecting electrode 1 through the electrode support assembly, and the dust collecting electrode 1 is connected After the high-voltage power supply 4 and the dust-collecting electrode 1 are connected to the high-voltage power supply 4, a non-uniform and strong electric field radiating outward is formed. The dust-collecting electrode 1 and the shielding tube 2 are connected and fixed by the electrode support assembly. At the same time, the shielding tube 2 is grounded to ensure The non-uniform electric field generated by the dust collecting electrode 1 is not disturbed by the outside world.

[0031] An electrode dust collection channel through which dust-laden gas passes is formed between the shielding tube 2 and the dust ...

Embodiment 2

[0045] combine Figure 5 The difference between this embodiment and the first embodiment is that: in this embodiment, the dust collecting electrode 1, the shielding tube 2 and the electrode support assembly form the electrostatic dust collecting unit in the electrostatic dust collecting device, and the electrostatic dust collecting units are arranged in parallel, The axes of the electrostatic precipitator units of each group are parallel to each other, and the shielding tubes 2 in each electrostatic precipitator unit are connected through conductors 7 .

[0046] The device can be implemented in a large-scale use environment and improve the overall dust collection efficiency. The adjacent shielding tubes 2 in each electrostatic dust collection unit are connected by conductors 7, so that each shielding tube 2 forms an equipotential body. , The electric fields in each group of electrostatic dust collection units do not interfere with each other due to the effect of electrostatic ...

Embodiment 3

[0048] combine Image 6 , the difference between this embodiment and the first embodiment is that the shielding tubes are multiple cylinders arranged in concentric circles, and the outermost shielding tubes are grounded.

[0049] Further, the shielding tubes are arranged radially outward in order from the dust collecting electrodes 1. The adjacent shielding tubes 2 are connected by a shielding tube support assembly, and a shielding tube dust collection channel is formed between the adjacent shielding tubes. The two ends of the dust collecting channel are open, and the two ends of the opening of the electrode dust collecting channel respectively form the air outlet and the air inlet in this embodiment.

[0050] Further, the shielding pipe support assembly is arranged at both ends of the dust collecting channel of the shielding pipe, namely the air outlet and the air inlet end.

[0051] Further, the shielding tube support rods 8 are all three, and the three shielding tube suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com