Auxiliary device for feeding limiting of stamping die

A technology of an auxiliary device and a stamping die, which is applied in the field of stamping dies, can solve the problems of poor safety of manual auxiliary fixing of stamping, and achieve the effect of simple structure and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

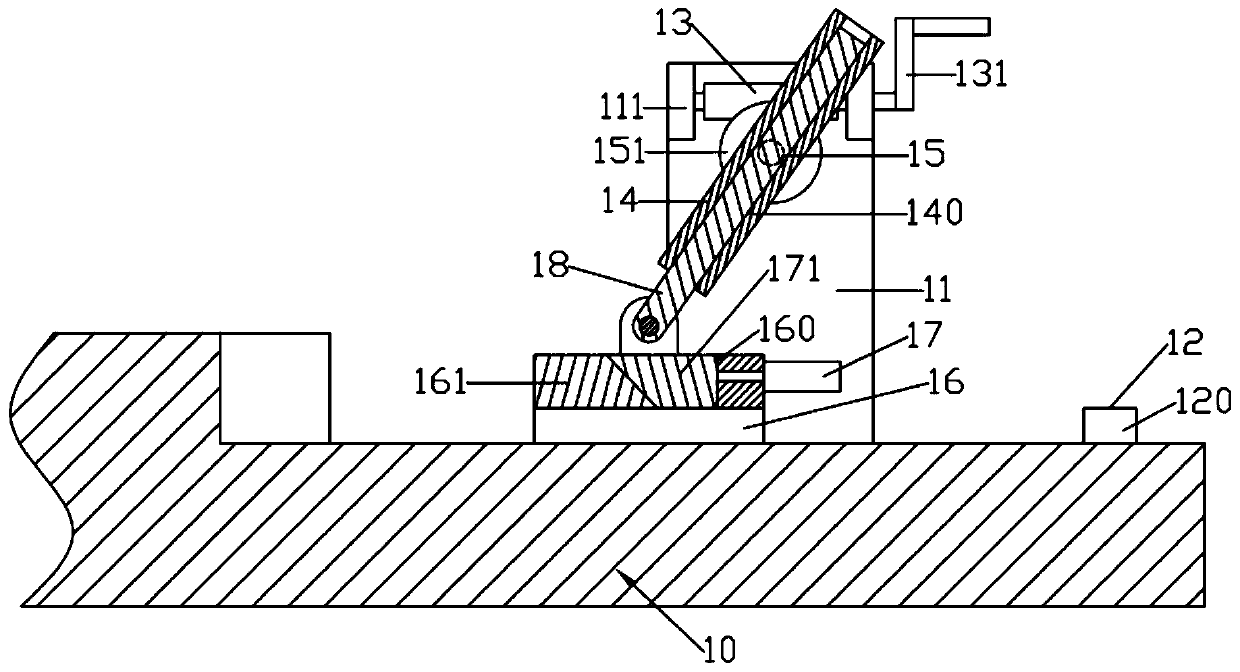

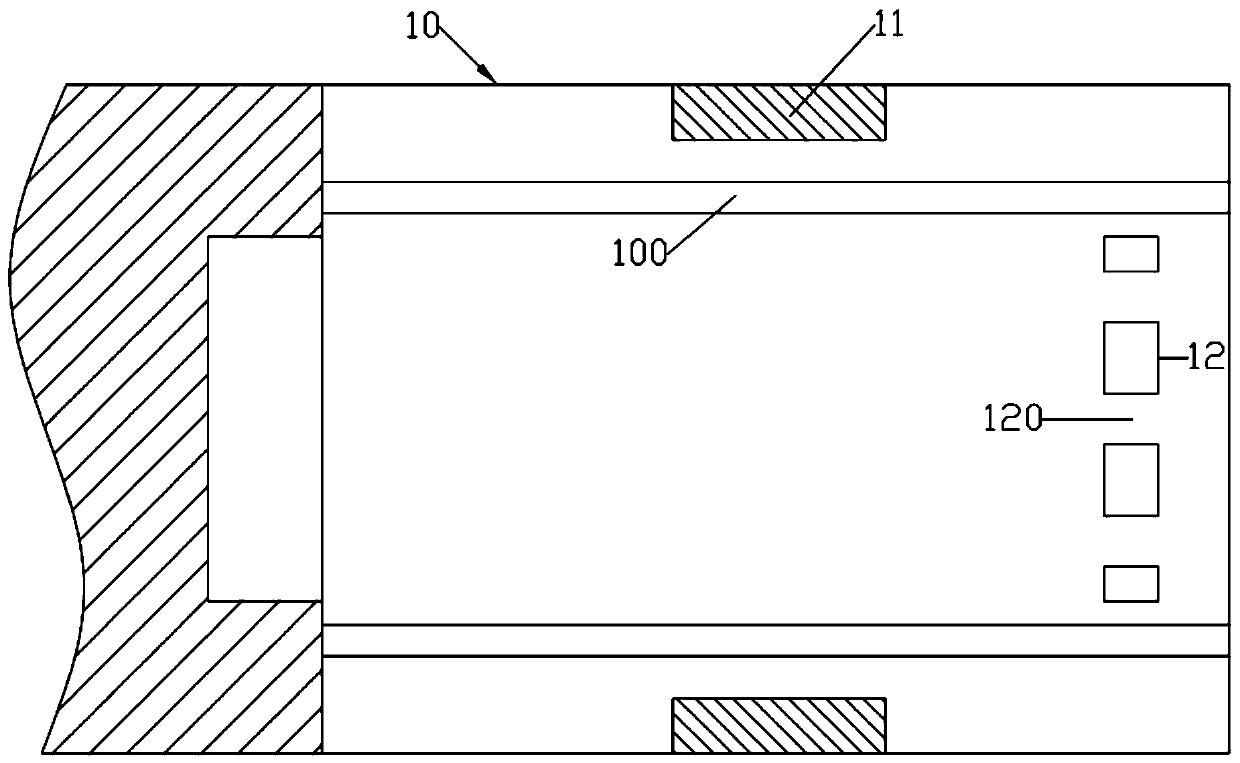

[0015] Such as figure 1 , figure 2 As shown, a stamping die feeding limit auxiliary device includes a support plate 10; the support plate 10 slides left and right and is provided with a "凵" shaped feed abutment plate 16 with the opening facing downward; the upper end surface of the support plate 10 The right end is molded with a cuboid-shaped limiting barrier 12 arranged in the front and rear direction; the limiting barrier 12 is formed with some avoidance grooves 120 that run through the left and right and the avoidance groove 120 divides the limiting barrier 12 into several parts; The height of the bar 12 is equal to the gap between the lower end surface of the horizontal part of the feed abutment plate 16 and the upper end surface of the support plate 10; The end face close to the straight part is flush; the left end face of the horizontal part of the feed abutment plate 16 is formed with several lifting grooves 160; The front and rear side walls of the front and rear si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com