Intelligent inspection robot for detecting running micro-leakage of power plant equipment and detection method thereof

A technology for equipment operation and intelligent inspection. It is applied to instruments, manipulators, measuring devices, etc. It can solve the problems of single information collection equipment, multiple fault detection of equipment that cannot be inspected, and one-sidedness, and achieve the effect of clear and accurate collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

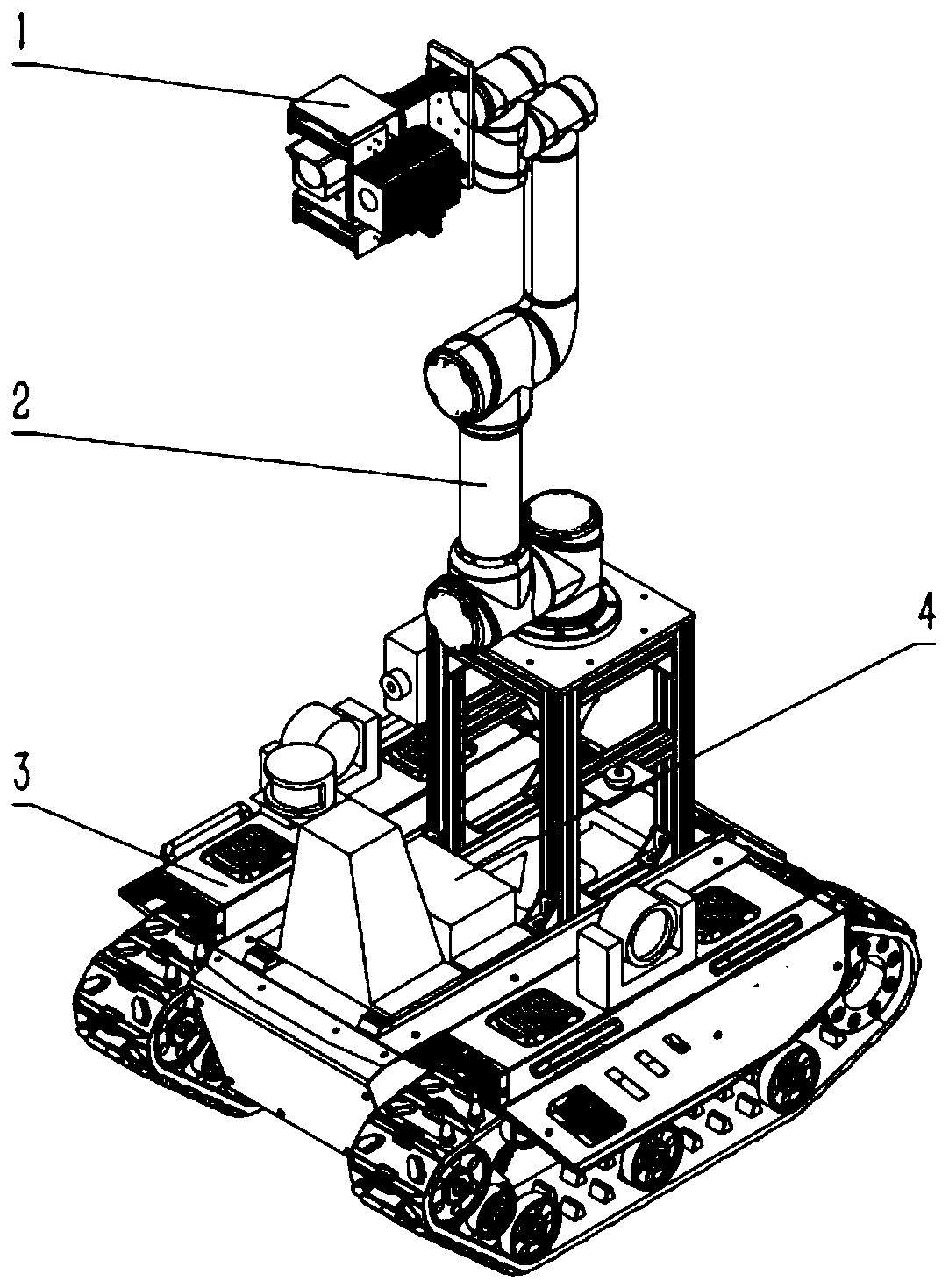

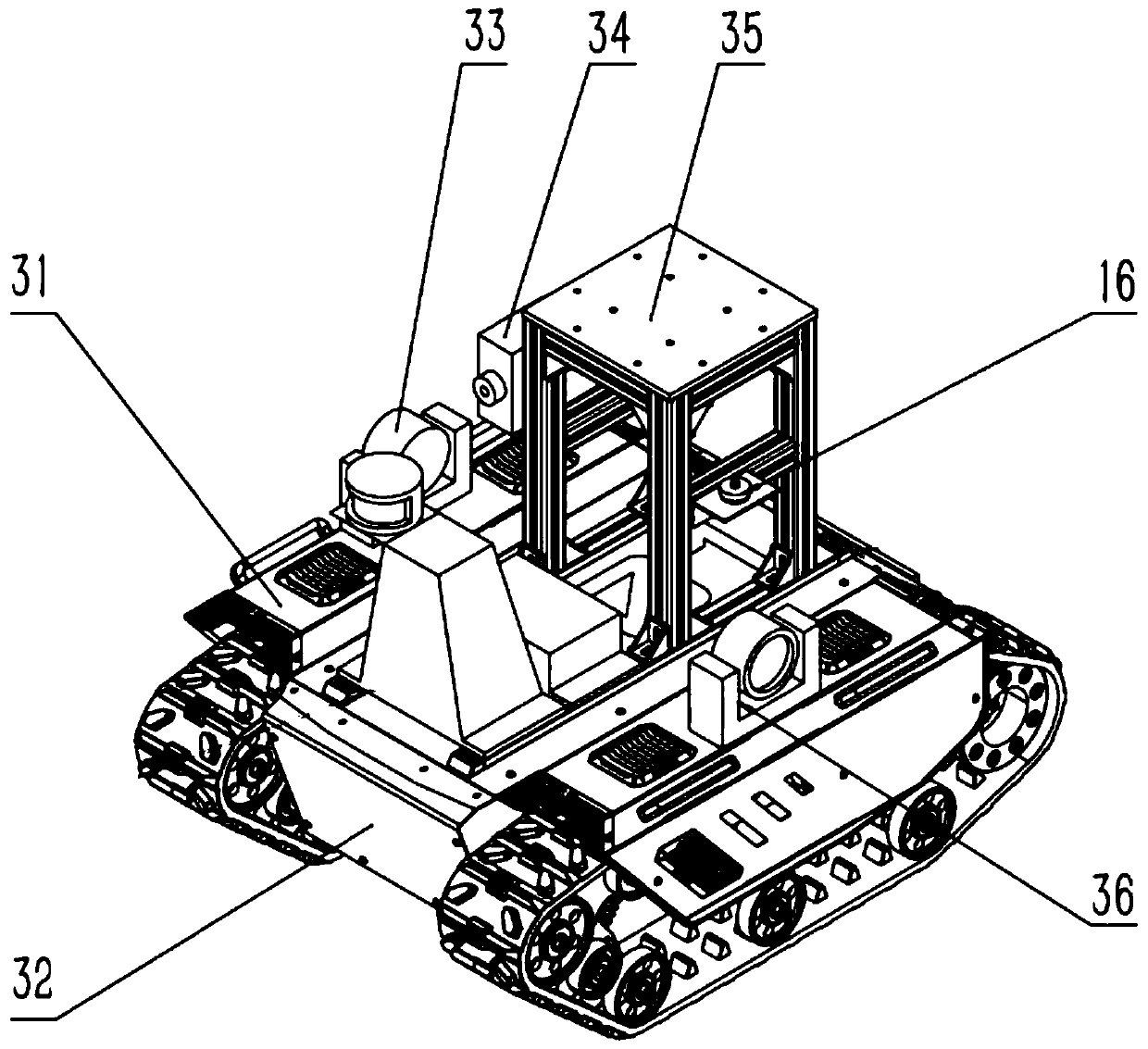

[0045] This embodiment provides an intelligent inspection robot for detection of micro-leakage in operation of power plant equipment, such as figure 1 , including autonomous inspection platform 3, robotic arm 2, on-site perception module 1 and industrial control module 4, where:

[0046] The autonomous inspection platform 3 is integrated with a robotic arm 2, an on-site sensing module 1 and an industrial control module 4. The on-site sensing module 1 is fixedly installed on the tool end of the robotic arm 2, and the working position of the on-site sensing module 1 is adjusted through the robotic arm 2. The industrial control module 4 Receive instructions from the remote control center, control the autonomous inspection platform 3 to move to each area to be detected, and wait for the on-site feature information collected by the on-site perception module 1 to be fed back to the remote control center through the industrial control module 4 .

[0047] The autonomous inspection pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap