A carton packaging line

A packaging line and carton technology, applied in the field of carton packaging line, can solve the problems of glue waste, uneven glue coating, instability of carton forming, etc., and achieve the effect of avoiding waste and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

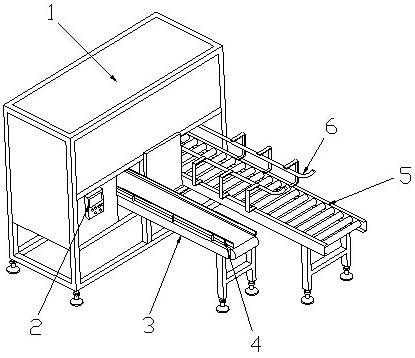

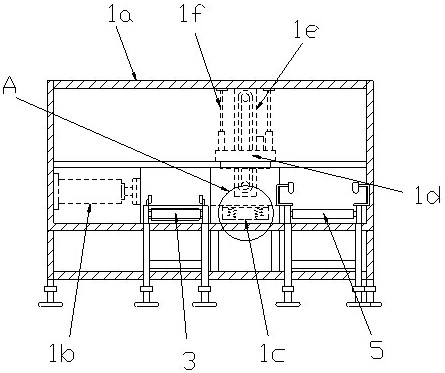

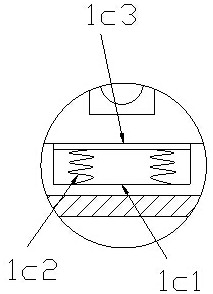

[0027]SeeFigure 1 - Figure 4 The present invention provides a carton packaging pipeline, which includes a host 1, a voltage controller 2, a feed conveying device 3, a tab 4, a discharge delivery device 5, a strip rod 6, and the front end of the host 1 A controller 2 is mounted on the surface, and the front end of the main unit 1 is arranged side by side from left to right, and the feed delivery device 3 and the discharge delivery device 5 are provided. The feed delivery device 3 and the discharge delivery device 5 Mechanically connected to the host 1, the tip end of the feed conveying device 3 is provided with a web 4, and the feed conveying device 3 and the tab 4 are welded by electric soldering, the top end of the discharge delivery device 5. A strip rod 6 is provided, the discharge delivery device 5 and the support lever 6 are fixedly connected, the main unit 1 by the body 1a, the push device 1b, the carton molding mechanism 1C, the extrusion mechanism 1D, the drive device 1E, th...

Embodiment 2

[0034]SeeFigure 5 - Figure 6The present invention provides a cartridge package pipeline, the spraper mechanism 1D5 by the storage box 1D51, the telescopic rod 1D52, the strut 1d53, the drainage tank 1D54, the whole flat head 1D55, the squeezing piece 1D56, the third spring 1D57, fixed plate The 1D58 is formed, and the retractable rod 1d52 is provided on one end of the storage box 1D 51, and the storage case 1d51 and the telescopic rod 1D 52 are fixed, and the retractable rod 1d52 is provided with a fixing plate 1D58, the telescopic The rod 1d52 and the fixing plate 1D58 mechanically connected, the third spring 1D 57 is attached to the surface of the stretch rod 1D 52, and the housing cassette 1D51 is provided with a strut 1d53, the storage box 1D51 and the strut 1D53 end one end. In the integrated structure, the strut 1d53 is provided with a finished head 1D55, and the entire flat head 1D55 is provided on both sides of the left and right sides, the entire flat head 1D55 and the wipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com