Two-gear coaxial electric drive system

An electric drive system, coaxial technology, used in control devices, transportation and packaging, vehicle components, etc., can solve problems such as inability to directly match high-speed motors, inability to achieve maximum speed, and reduce vehicle economy, and achieve excellent driving comfort. performance, good start-up and acceleration, reduced size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

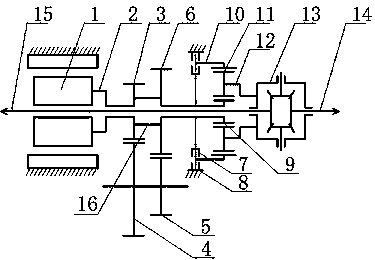

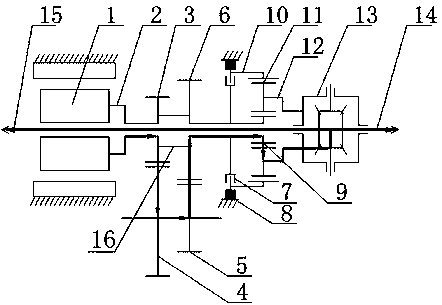

[0026] The present invention provides a two-speed coaxial electric drive system through improvement, including a motor output shaft 2 arranged on the right side of the drive motor 1, the right side of the motor output shaft 2 is inserted into the middle of the motor output gear 3, and the motor output gear 3 The front end meshes with the large gear 4 of the double gear, the large gear 4 of the double gear is coaxial with the pinion 5 of the double gear at the right end, the back of the pinion 5 of the double gear meshes with the gear on the intermediate shaft 6, and the outer diameter of the intermediate shaft 6 The right end of the surface is connected to the clutch 7 through a spline, and the right end of the clutch 7 is provided with a sun gear 9, and the inner middle part of the sun gear 9 is arranged on the intermediate shaft 6 through a spline, and the outer diameter surface of the sun gear 9 meshes with the planetary gear 11, and the planetary gear 11 The outer diameter ...

Embodiment 2

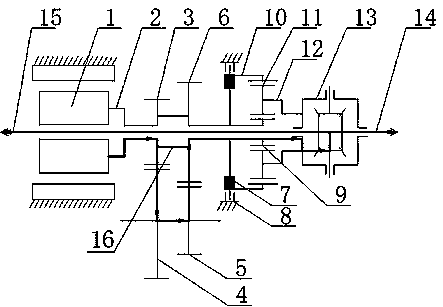

[0029] The present invention provides a two-speed coaxial electric drive system through improvement, such as image 3As shown, when the vehicle speed reaches the set high-speed working condition (the set shifting speed is 80km / h), the system will be combined to the second gear working condition, and the drive motor 1 starts to drive the motor output gear through the motor output shaft 2 on the right 3 to rotate, then the motor output gear 3 can make the double gear large gear 4 rotate, then the double gear large gear 4 can make the coaxial double gear pinion 5 move, and then the double gear pinion 5 passes through The gear on the intermediate shaft 6 makes the intermediate shaft 6 rotate, and then the intermediate shaft 6 passes through the auxiliary stabilization mechanism 16. After the driving gear 165 inside the mechanism 16 drives the driven gear 166 to achieve deceleration and stability, the power from the drive motor 1 passes through the intermediate The shaft is transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com