Passenger car passenger armrest bracket mounting structure and mounting method thereof

A technology of armrest bracket and installation structure, which is applied to vehicle components, transportation and packaging, and special positions of vehicles, etc. It can solve problems such as difficult molding, complex structure of three-claw passenger armrest bracket, and failure of passenger armrests, so as to reduce passenger armrests. Failure problems, easy control of production quality, and simple shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

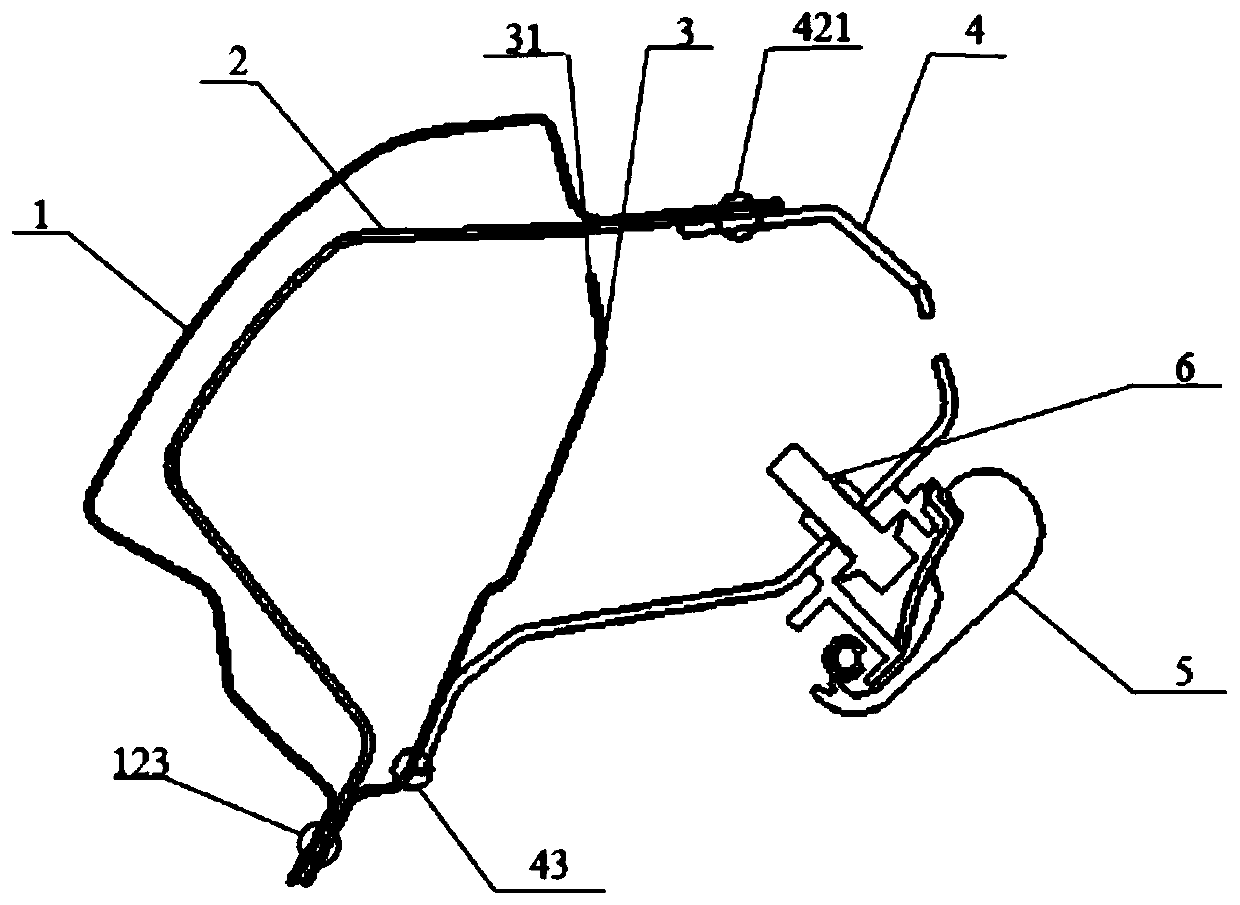

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

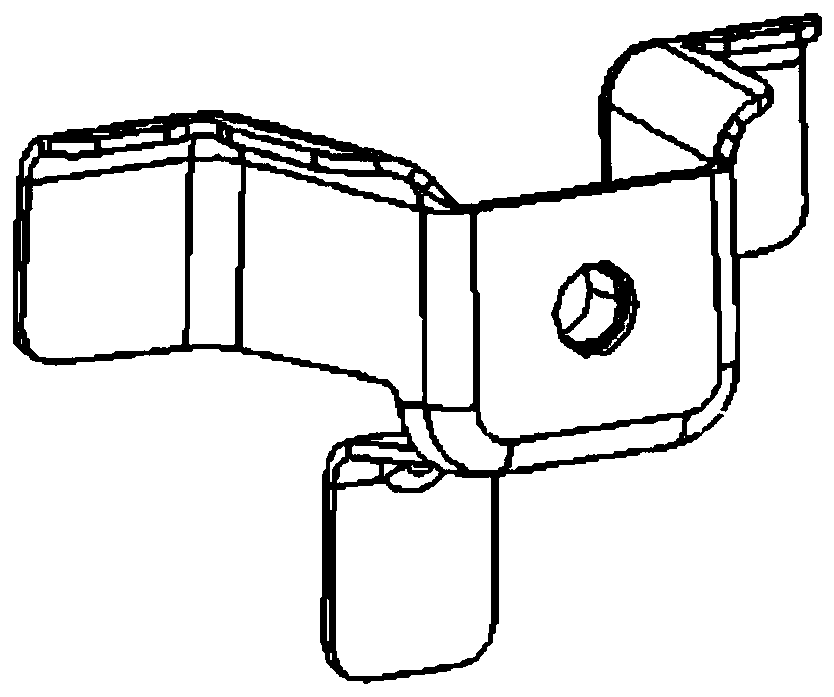

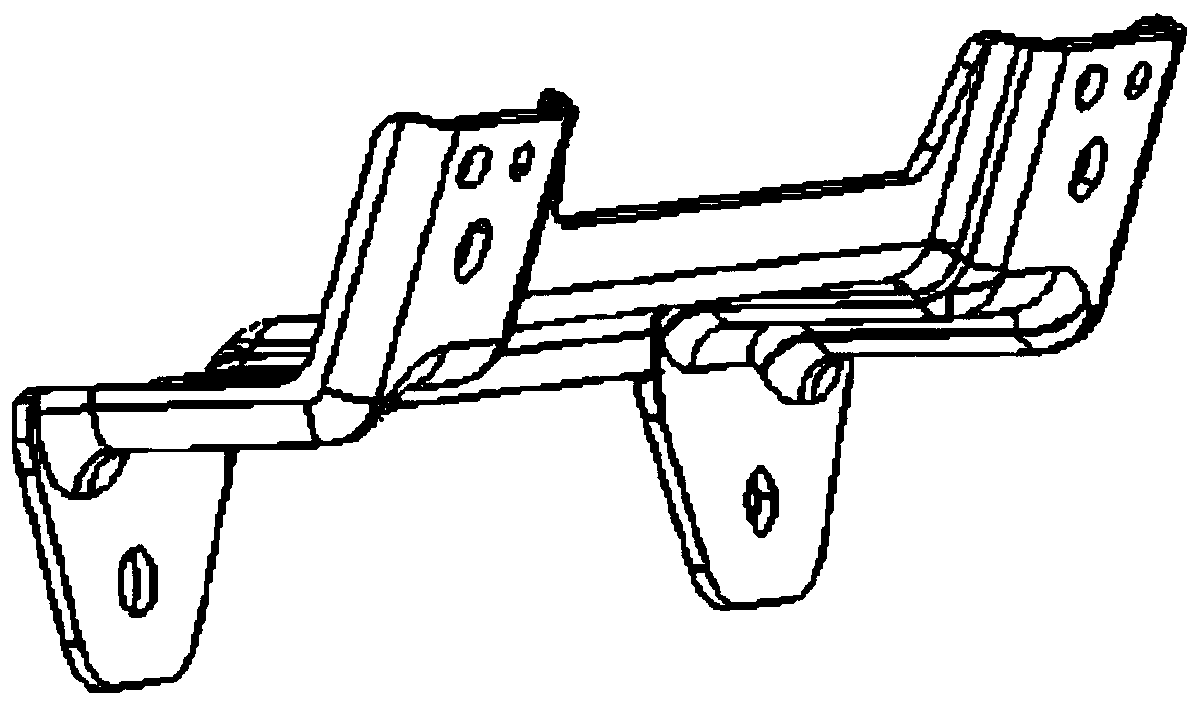

[0020] The installation structure of the passenger armrest bracket of the passenger car of the present invention comprises a side wall outer panel 1, a side wall edge beam reinforcement plate 2, a side wall inner panel 3, a passenger armrest bracket 4 and a passenger handrail 5, a side wall outer panel 1, a side wall edge beam The lower part of the reinforcing plate 2 and the side wall inner panel 3 is welded together by the first welding spot 123, and the position where the upper part of the side wall inner panel 3 is welded with the side wall outer panel 1 and the side wall side sill reinforcement plate 2 forms a gap 31, and the gap 31 The purpose is to prevent the occurrence of four-layer welding during the welding process, which may lead to bad solder joints. The passenger armrest bracket 4 is welded together with the side wall side sill reinforcement plate 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com