Anti-splashing control method for high-temperature molten metal transfer crane

A technology of high-temperature melting and control method, which is applied in the direction of transportation and packaging, load hanging components, cranes, etc., can solve problems such as increasing the running time of cranes, reducing product quality and production efficiency, safety accidents, etc., and achieves the elimination of load hanging Oscillation, improved transient control performance, fast and accurate positioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

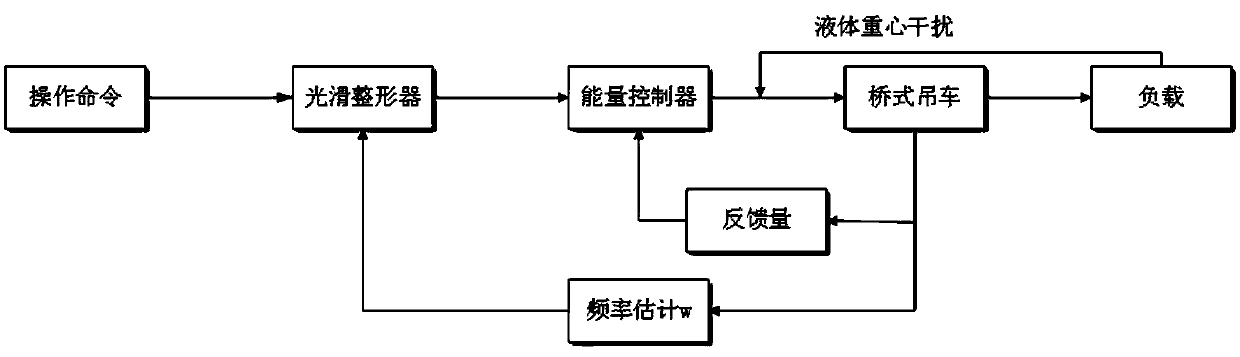

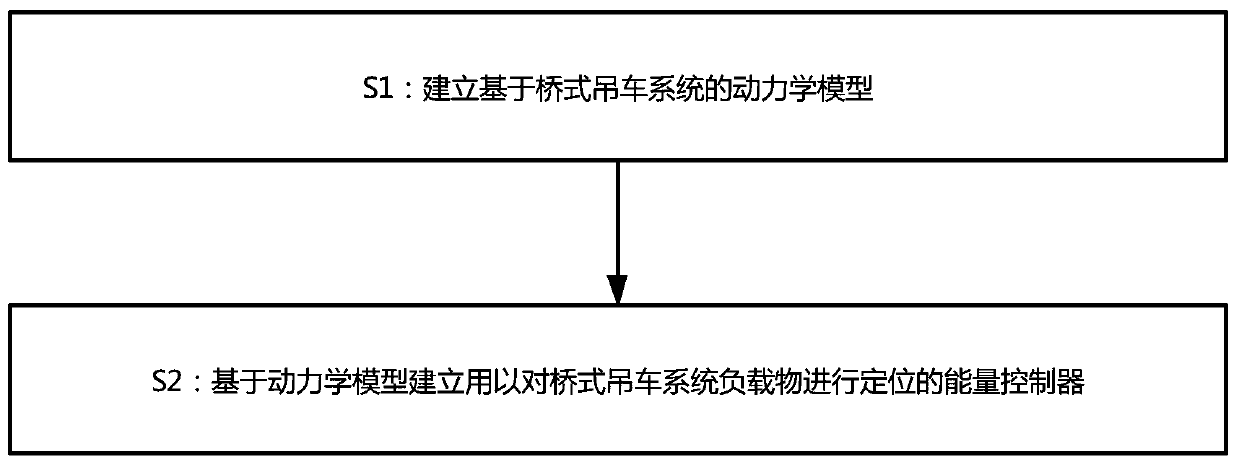

[0030] see figure 1 , figure 2 , image 3 , the anti-splash control method of the high-temperature molten metal transfer crane in the present embodiment includes the following steps:

[0031] S1: Establish a dynamic model based on the overhead crane system;

[0032] S2: Establish an energy controller for positioning the load of the overhead crane system based on the dynamic model.

[0033] Here, the energy controller realizes fast and accurate positioning of the load of the bridge crane system, and effectively restrains its swing, which can better realize the anti-swing positioning of the trolley.

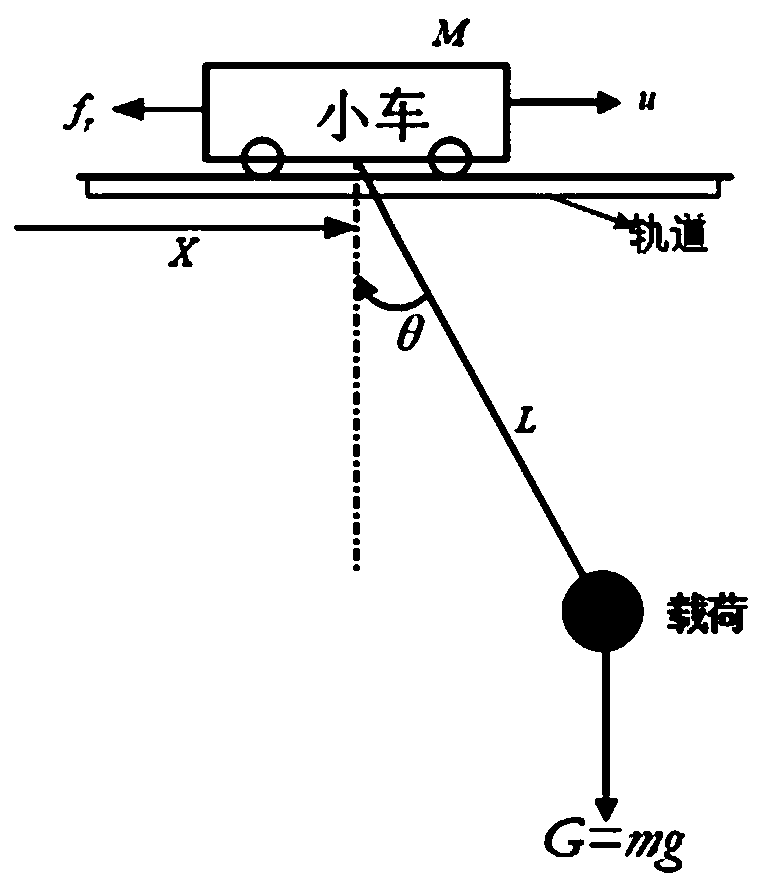

[0034] Step S1 specifically includes:

[0035] S11: Establish a two-dimensional bridge crane dynamic model according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com