Preparation method of alkali metal-based fluorophlogopite sheet

A technology of fluorphlogopite and alkali metal fluoride, which is applied in the direction of aluminum silicate and silicate, can solve the problems of artificial mica crystals, single formula, and poor versatility, and achieve fewer types of raw materials, simple operation, and universal strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

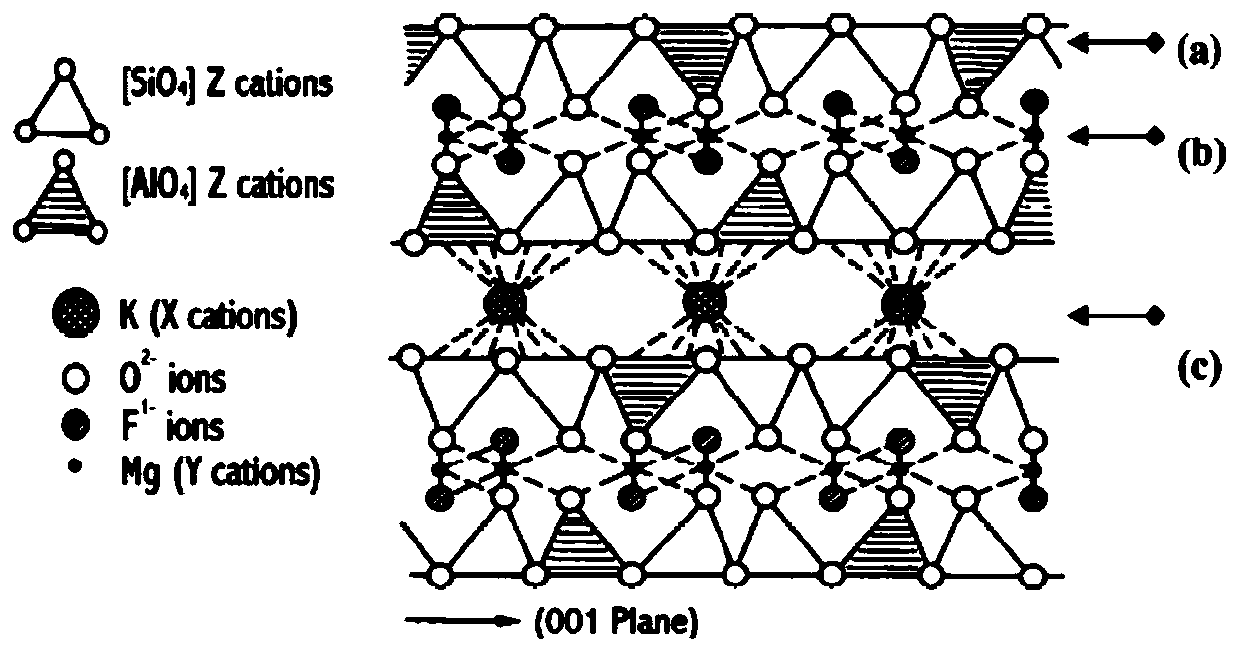

Image

Examples

Embodiment 1

[0034] A preparation method with conductive sodium type fluorphlogopite mica sheet, comprising the steps of:

[0035] (1) After the raw materials pass the inspection, use a grinder to grind to 90 mesh and then dry to make the water content 0.5%, and set aside;

[0036] (2) Take the raw materials according to the mass ratio, wherein the components of the raw materials are: 45% of quartz sand, 25% of seawater magnesia, 13% of alumina, 8% of magnesium fluoride, 9% of sodium fluoride, mixed and stirred evenly mixed raw materials;

[0037] (3) Add the mixed raw materials obtained in step (2) into the internal heat furnace, first add 2 / 3 of the total amount; the internal heat furnace is made of three-grade high-alumina refractory bricks, and the mixed raw materials are compacted with heavy objects to increase the material density , and discharge excess air; energized for melting, the raw materials are heated and decomposed in the internal heating furnace, the molten gas is volatili...

Embodiment 2

[0043] A kind of preparation method with insulating performance potassium type fluorine phlogopite sheet, comprises the following steps:

[0044] (1) After the raw materials pass the inspection, use a grinder to grind to 80 mesh and then dry to make the water content 0.4%, and set aside;

[0045] (2) Take the raw materials according to the mass ratio, wherein the components of the raw materials are: 43% of quartz sand, 24% of seawater magnesia, 12% of aluminum oxide, 7% of magnesium fluoride, 14% of potassium fluoride, mixed and stirred evenly mixed raw materials;

[0046] (3) Add the mixed raw materials obtained in step (2) into the internal heat furnace, first add 2 / 3 of the total amount; the internal heat furnace is made of three-grade high-alumina refractory bricks, and the mixed raw materials are compacted with heavy objects to increase the material density , and exhaust the excess air; power on for melting, the raw materials are heated and decomposed in the inner heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com