Asphalt concrete self curing agent and application method thereof

A kind of asphalt concrete, self-maintenance technology, applied in the field of traffic engineering, can solve the problems of poor durability of asphalt concrete roads, and achieve the effect of keeping the performance of asphalt unchanged, prolonging the service life and improving the anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

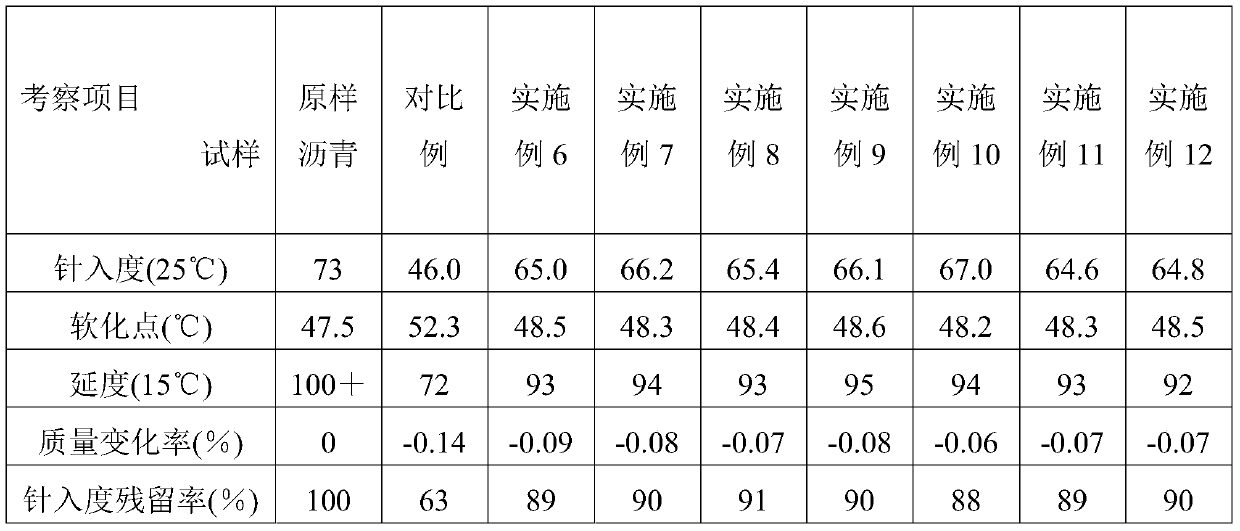

Examples

Embodiment 1

[0025] This embodiment provides a self-curing agent for asphalt concrete, including modified zeolite and asphalt regeneration agent (physical index: 60 °C viscosity 11000m 2 / s, saturated + aromatic content 75.43%, gum + asphaltene content 24.03%). Its preparation method is:

[0026] S1. Calcining the coarse and fine components of dual-stage zeolite with a particle size porosity of 10-90% in an electric furnace at 400°C for 1 hour, then soaking in 0.1mol / L NaOH solution for 2 hours after natural cooling, and then Spray a composite coupling agent into the zeolite under the stirring state of 800~1200rpm (the composite coupling agent is a mixture of silane coupling agent, titanate and aluminate with a mass ratio of 3:1:1, and the total amount of natural zeolite The mass ratio of the mass to the composite coupling agent is 50:1), and the coarse component modified zeolite and the fine component modified zeolite are prepared.

[0027] S2. Place the modified zeolite obtained in S1 ...

Embodiment 2

[0029] This embodiment provides a self-curing agent for asphalt concrete, including modified zeolite and asphalt regeneration agent (physical index: 60 °C viscosity 11000m 2 / s, saturated + aromatic content 75.43%, gum + asphaltene content 24.03%). Its preparation method is:

[0030] S1. Calcining the coarse and fine components of dual-graded zeolite with a particle size porosity of 10-90% in an electric furnace at 400°C for 1.5 hours, then soaking in 0.12mol / L NaOH solution for 1 hour after natural cooling, and then Spray the composite coupling agent into the zeolite under the stirring state of 800~1200rpm (the composite coupling agent is a mixture of silane coupling agent, titanate and aluminate with a mass ratio of 2.5:1.2:0.8, zeolite and composite The mass ratio of the coupling agent is 10:1), and the coarse component modified zeolite and the fine component modified zeolite are prepared.

[0031] S2, place the modified zeolite obtained in S1 in a negative pressure envir...

Embodiment 3

[0033] This embodiment provides a self-curing agent for asphalt concrete, including modified zeolite and asphalt regeneration agent (physical index: 60 °C viscosity 11000m 2 / s, saturated + aromatic content 75.43%, gum + asphaltene content 24.03%). Its preparation method is:

[0034] S1. Calcining the coarse and fine components of dual-graded zeolite with a particle size porosity of 10 to 90% in an electric furnace at 500°C for 1 hour, then soaking in 0.08mol / L NaOH solution for 2 hours after natural cooling, and then Spray the composite coupling agent into the zeolite under the stirring state of 800~1200rpm (the composite coupling agent is a mixture of silane coupling agent, titanate and aluminate with a mass ratio of 3.5:0.8:1.2, and the zeolite and composite The mass ratio of the coupling agent is 100:1), and the coarse component modified zeolite and the fine component modified zeolite are prepared.

[0035] S2. Place the modified zeolite obtained in S1 in a negative pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap