Large-diameter rock-socketed single pile grouting construction method for offshore wind power

It is a construction method and technology of TV University, which is applied in wind power generation, sheet pile wall, foundation structure engineering, etc. It can solve the problems of difficult underwater monitoring, borehole collapse, and small grouting gap, so as to solve the problem of uneven distribution and avoid Aging bonding, improving safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

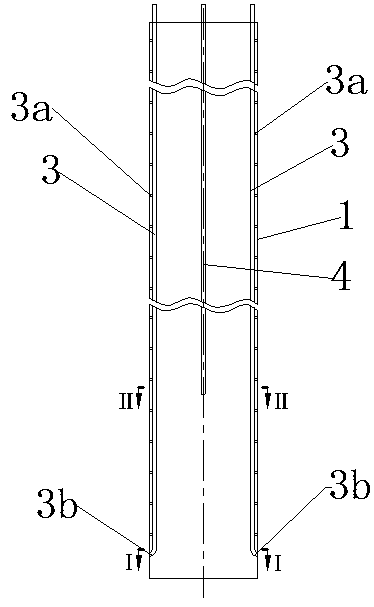

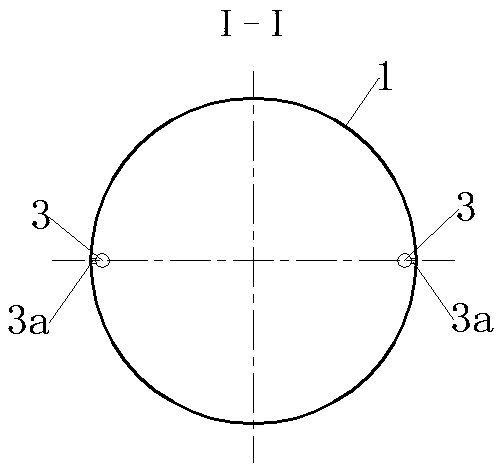

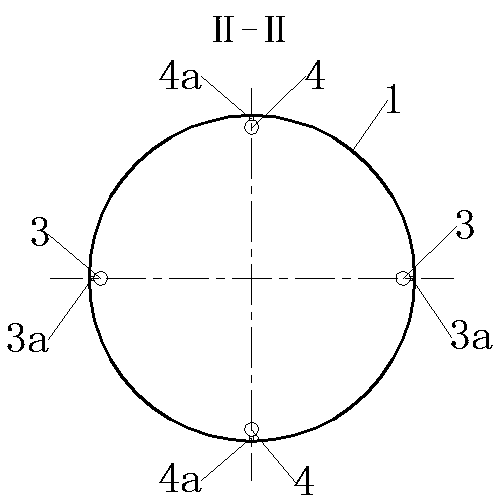

[0024] The grouting construction method of the large-diameter rock-socketed single pile for offshore wind power is further described below in conjunction with the accompanying drawings.

[0025] figure 1 , 2 , 3 shows the structural diagram of the prefabricated grouting pipe of the steel pipe pile. The inner wall of the steel pipe pile 1 is provided with two first prefabricated grouting pipes 3 fixed by a plurality of first support rods 3a and two second prefabricated grouting pipes 4 fixed by a plurality of second support rods 4a. The grouting pipes 3 and the second prefabricated grouting pipes 4 are evenly distributed on the inner wall of the steel pipe pile 1 alternately. The first prefabricated grouting pipe 3 communicates with the first grouting port 3b provided on the pile wall, and the second prefabricated grouting pipe 4 communicates with the second grouting port 4b provided on the pile wall. The second grouting opening 4b is located above the first grouting opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com