Novel water-stop and sealing dual-purpose water-stop belt for secondary lining end part of tunnel

A technology for waterstops and tunnels, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems of large number of planks, difficulty in completely sealing, and excessive slurry leakage at the ends, so as to improve installation quality and reduce gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

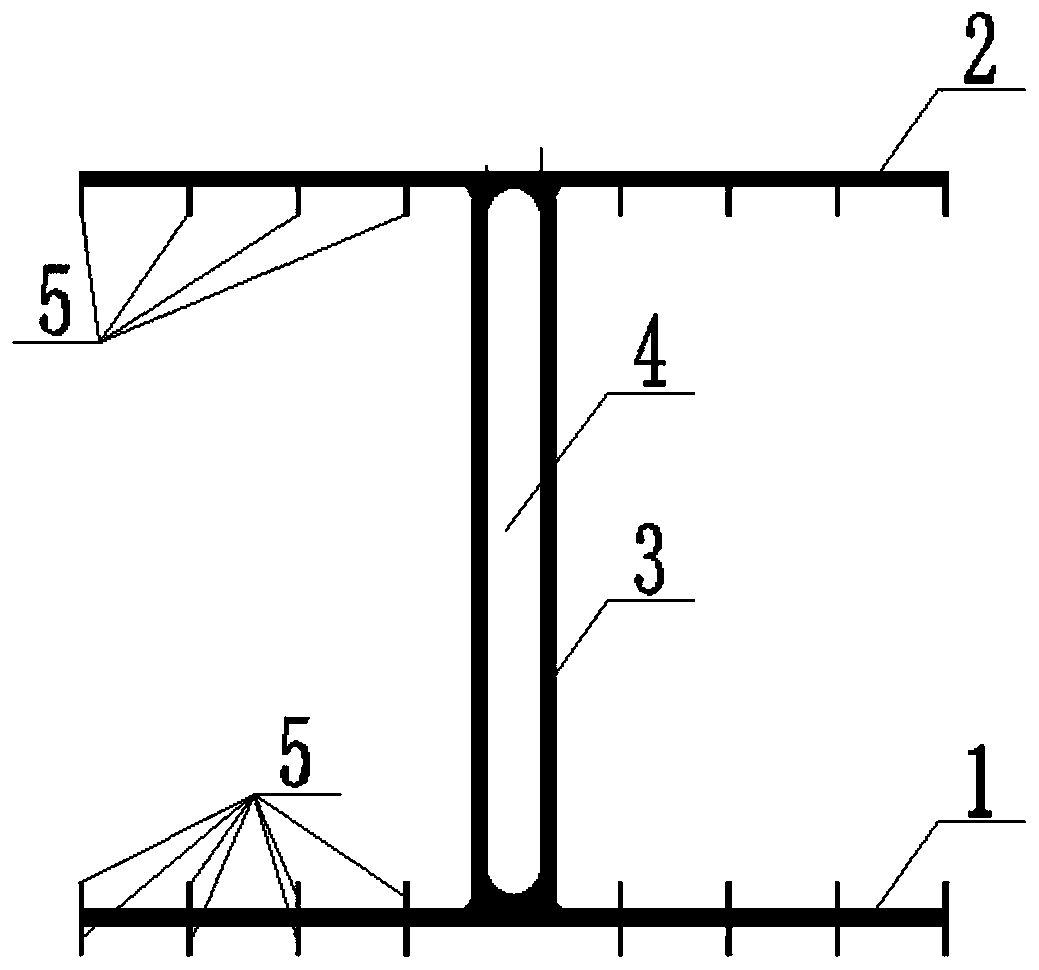

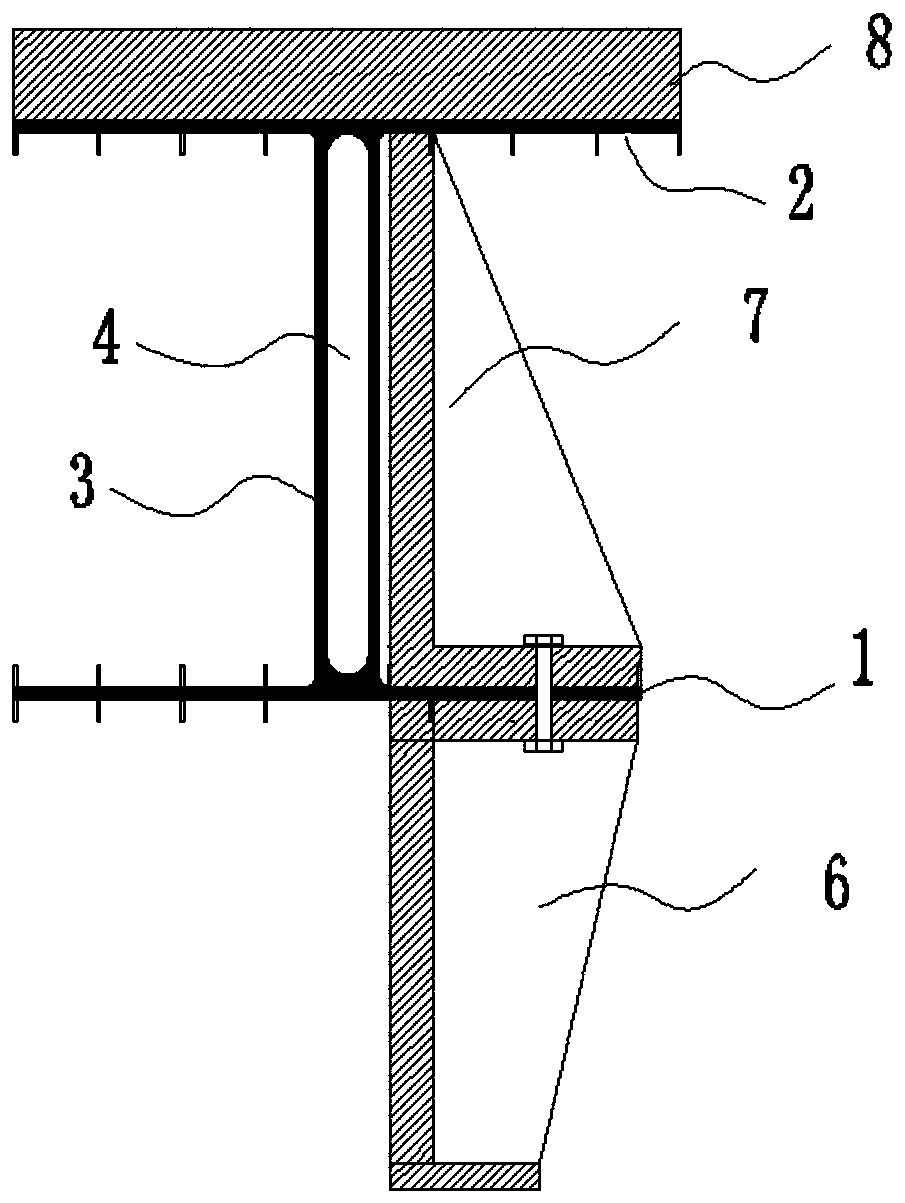

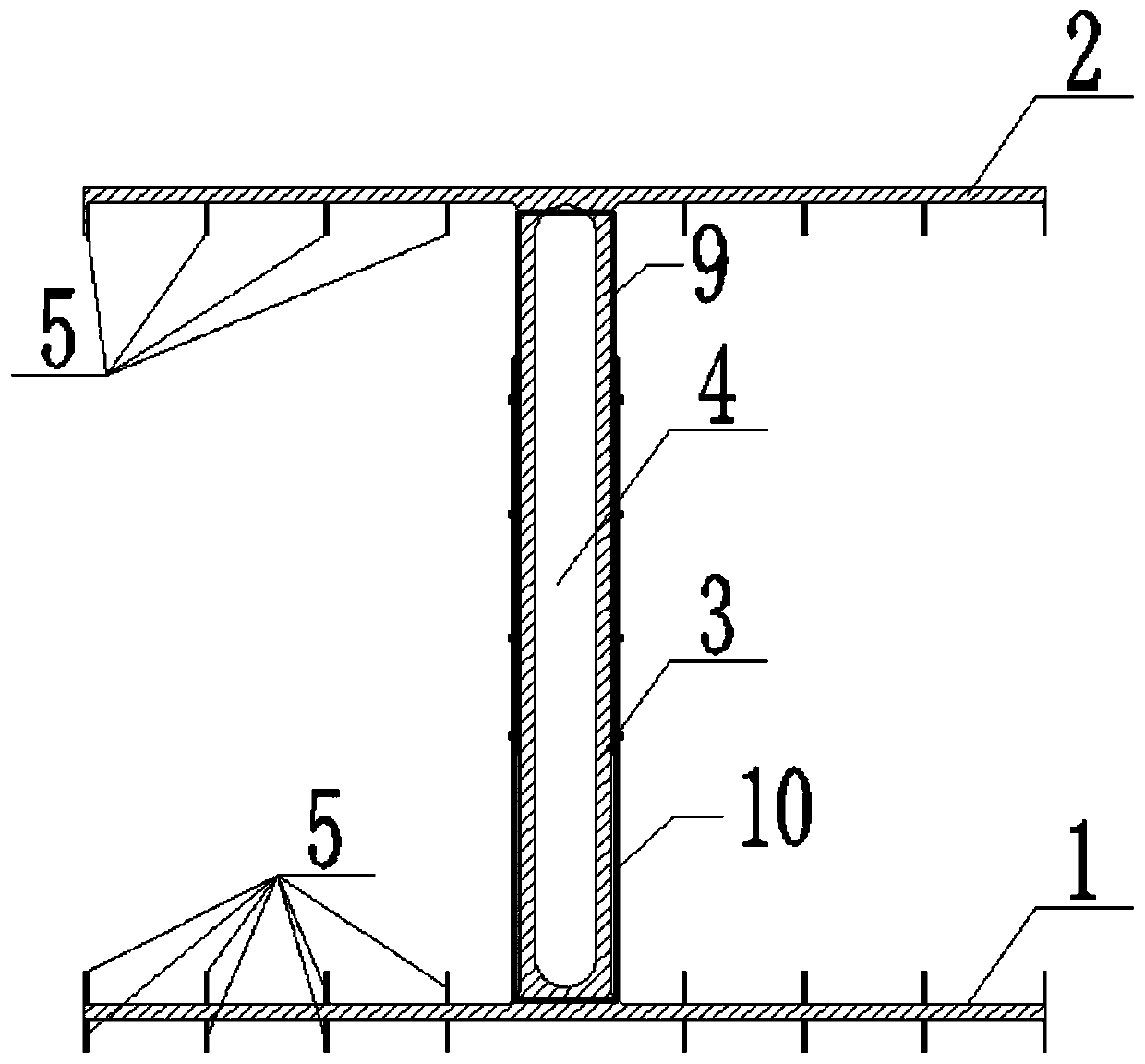

[0034] like figure 1 As shown, a new type of double-purpose waterstop for water-stop sealing at the end of the second lining of the tunnel, including:

[0035] Back-adhesive waterstop unit 2 for sticking to the tunnel ring waterproofing board;

[0036] A mid-buried waterstop unit 1 for being embedded in the concrete structure layer of the second lining of the tunnel; and

[0037] The elastic unit 3 connected between the back-attached waterstop unit 2 and the mid-buried waterstop unit 1, the elastic unit 3 expands and contracts to adjust the position of the back-attached waterstop unit 2 and the mid-buried waterstop unit 1 spacing.

[0038] Further, the elastic unit 3 is provided with an airbag 4 inside, and the airbag 4 is inflated or deflated to make the elastic unit 3 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com