Stator winding embedding method of multi-phase low-voltage large-capacity direct-drive wind turbine

A large-capacity, stator-driven technology, used in the manufacture of motor generators, electric components, electrical components, etc., can solve the problems of time-consuming consumables, many joints, etc., to improve the wire embedding speed, the motor structure is simple, and the wire embedding quality is reliable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

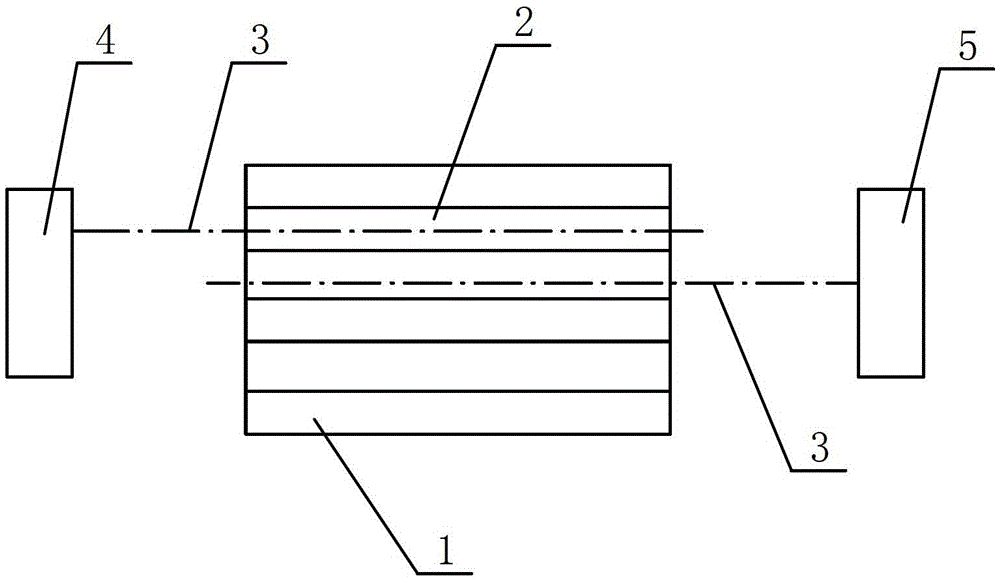

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

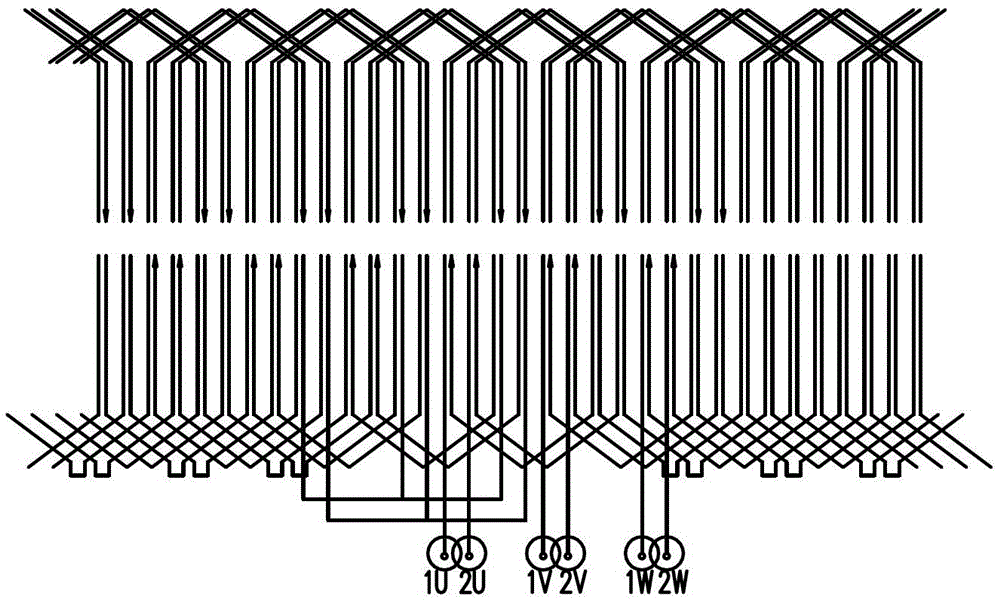

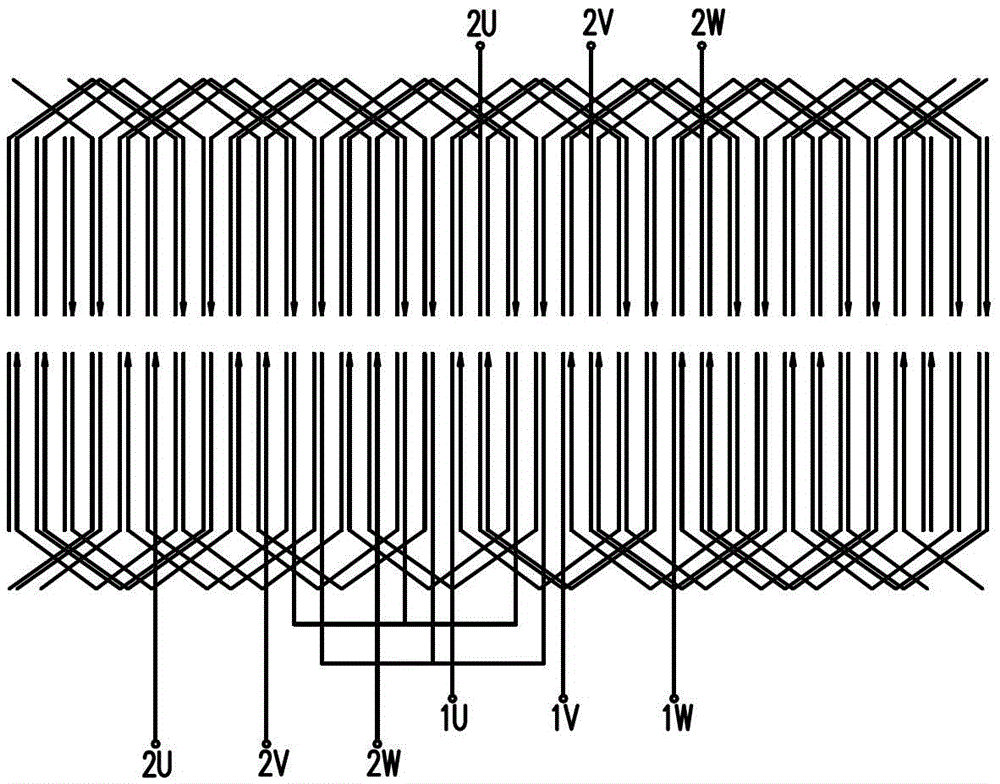

[0017] see figure 2 and image 3 As shown, in this embodiment, a multi-phase low-voltage large-capacity direct drive wind power generator stator winding embedding method, the stator 1 single embedding slot 2 needs to be wound with 90 copper wires 3, the specific embedding method is :

[0018] a: the first pay-off reel 4 and the second pay-off reel 5 are respectively placed on both sides of the stator 1;

[0019] b: Lead the copper wires 3 of the first pay-off reel 4 and the second pay-off reel 5 into two adjacent wire embedding slots 2 respectively for embedding wire;

[0020] c: When the number of wires embedded in the wire slot by the first pay-off reel 4 is 45, the copper wires of the first pay-off reel 4 are directly introduced into another wire slot, and the second pay-off reel 5 Wind the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com