A device and method for measuring the equivalent diameter of blast holes

An equivalent diameter and hole-breaking technology, applied in measuring devices, using fluid devices, instruments, etc., can solve the problems of inaccurate measurement, large human control factors, and inability to meet the standard requirements of equipment assessment, and achieve reliable and significant work. Economic benefits, principle feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

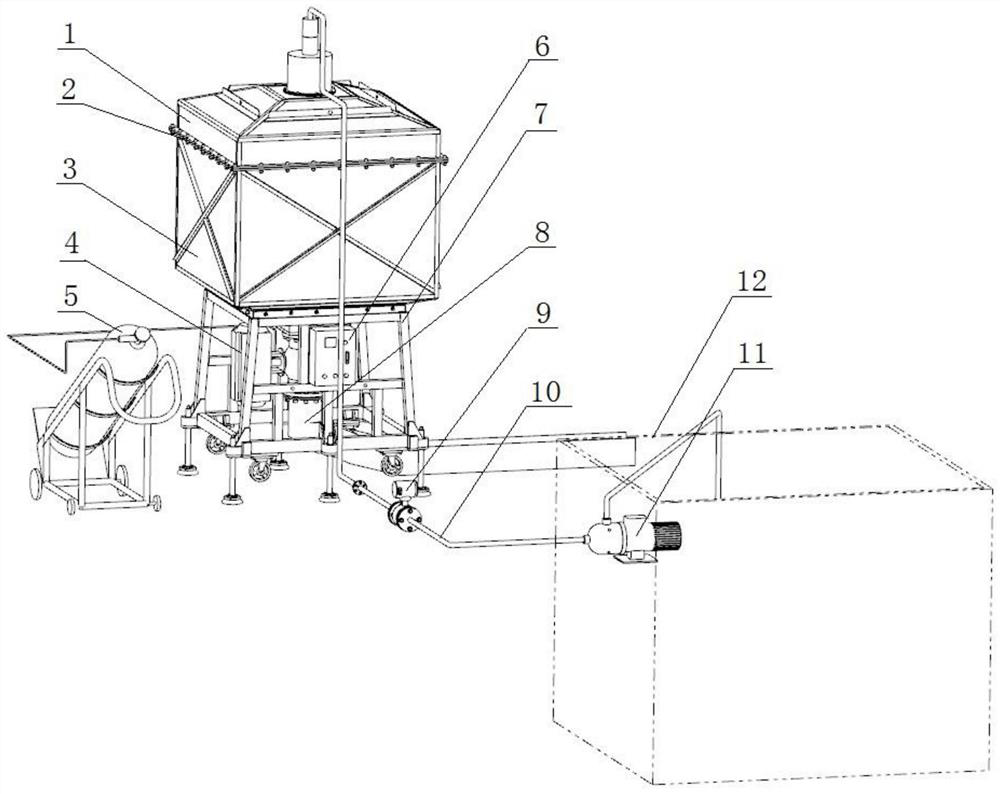

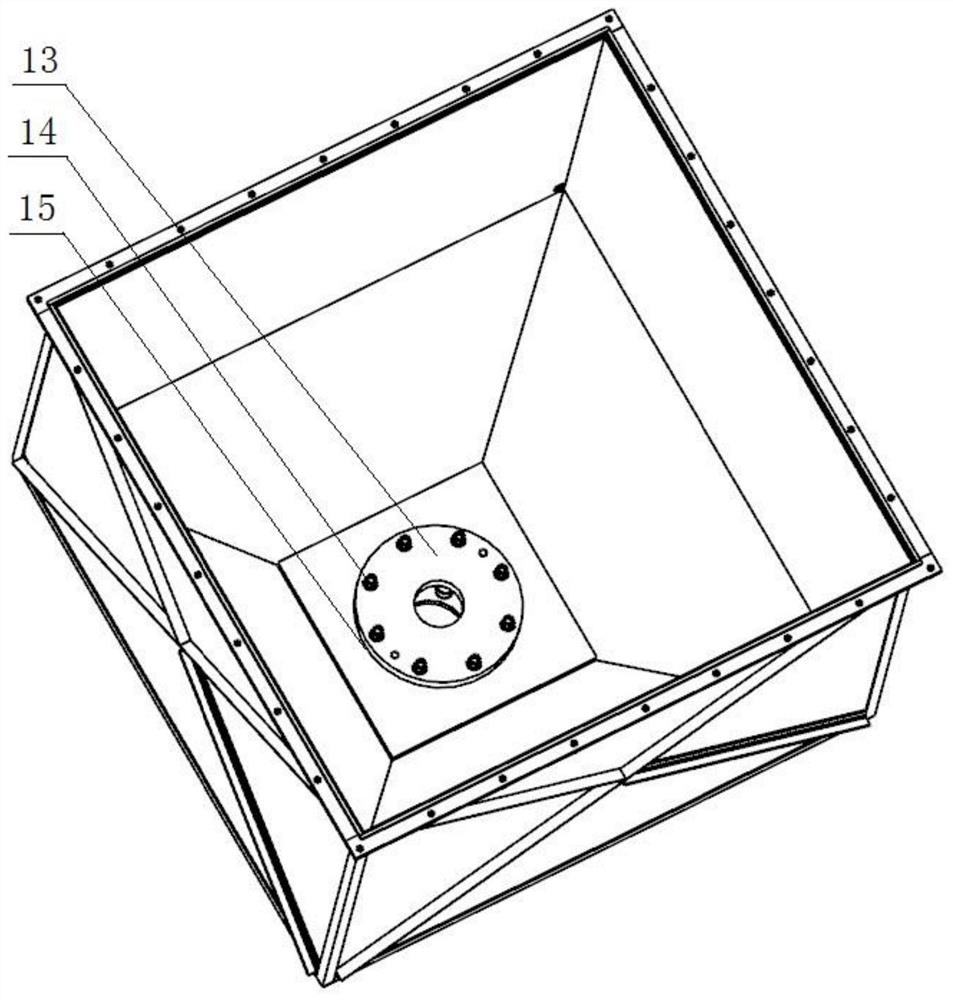

[0028] Such as figure 1 and figure 2 As shown, the device proposed by the present invention for measuring the equivalent diameter of blast holes includes a water tank, a water pump, a flow meter and a control valve.

[0029] There is an opening at the bottom of the water tank, and the aperture is larger than the maximum aperture of the hole in the target plate to be tested. The maximum aperture of the hole refers to the maximum value of the distance between any two points on the edge of the hole. An installation hole is provided on the edge of the opening at the bottom of the water tank, which can seal and fix the target board to be tested at the opening at the bottom of the water tank.

[0030] The upper part of the water tank has a water inlet and a water level marking line, and a water level control switch is arranged at the water level marking line on the upper part of the water tank; the water inlet of the water tank is connected to the water pump through a pipeline, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com