Determination method for content of carbon black

A technology of carbon black content and measurement method, which is applied in the direction of weighing by removing certain components, can solve the problems of poor repeatability and inaccurate measurement of carbon black content, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

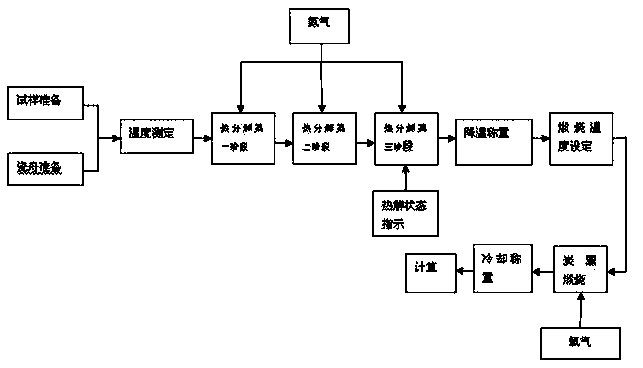

Method used

Image

Examples

Embodiment 1

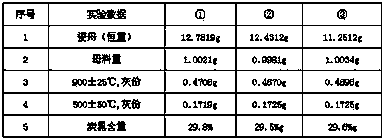

[0034] Example 1 The test method of carbon black content in calcium carbonate-containing plastic product A

[0035] This test method includes the following steps:

[0036] Step 1. Preparation stage: Check that the pressure of nitrogen and oxygen cylinders should be less than 1MPa to ensure no air leakage;

[0037] Porcelain boat should be heated to 550°C to remove its attached water and impurities, weigh the porcelain boat m (constant weight) at room temperature to be 12.7819g, and set aside; the sample (including CaCO 3 The black masterbatch (referred to as masterbatch) is baked at 95°C for 2 hours to remove the attached moisture of the sample, weigh the masterbatch m1=1.0021g at room temperature, and set aside; connect the test equipment.

[0038] Step 2. Use a carbon black content tester to perform pyrolysis and calcination tests on the masterbatch:

[0039] Place the porcelain boat with the masterbatch in the center of the quartz tube of the carbon black content tester...

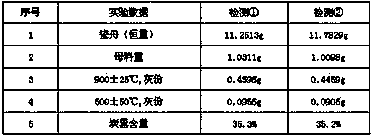

Embodiment 2

[0056] Example 2 The test method of carbon black content in the calcium carbonate-containing plastic product B

[0057] In this example, the test sample gets the same black masterbatch containing calcium carbonate in Example 1, and its carbon black content is 30 ± 1%; the calcium carbonate content is about 30%.

[0058] The test steps are basically the same as in Example 1, the difference is:

[0059] Step 1. In the preparation stage: the porcelain boat m (constant weight) is 12.4312g, and the masterbatch m1 is 0.9981g;

[0060] Step 3. Weighing after the masterbatch is completely pyrolyzed: when the exhaust of the quartz tube does not make the lime water turbid, stop the tube electric furnace

[0061] Heating; when the temperature drops to 400°C, switch on and off the nitrogen gas, so that the masterbatch in the porcelain boat gradually drops to room temperature, and then weigh the weight of the porcelain boat with the pyrolyzed masterbatch m2 = 0.4670g;

[0062] Step 4. Ca...

Embodiment 3

[0065] Example 3 The test method of carbon black content in calcium carbonate-containing plastic products C

[0066] In this example, the test sample gets the same black masterbatch containing calcium carbonate in Example 1, and its carbon black content is 30 ± 1%; the calcium carbonate content is about 30%.

[0067] The test steps are basically the same as in Example 1, the difference is:

[0068] Step 1. In the preparation stage: the porcelain boat m (constant weight) is 11.2512g, and the masterbatch m1 is 1.0034g;

[0069] Step 2. Use a carbon black content tester to perform pyrolysis and calcination tests on the masterbatch:

[0070] Sample pyrolysis stage and pyrolysis standard: the ceramic boat placed in the quartz tube is heated to make the master material in the porcelain boat warm

[0071] The temperature is gradually increased, while heating, nitrogen is passed through the quartz tube, and the masterbatch is pyrolyzed in the nitrogen environment; the pyrolysis pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com