Corrosive agent for displaying fine austenite grain boundary of low-carbon microalloyed steel and using method

A technology of austenite grain boundary and corrosive agent, which is applied in the display field of fine austenite grain boundary of low-carbon micro-alloy steel, can solve the problems of explosion hazard and damage to instruments, and achieve the effect of increasing safety and reducing harm to human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

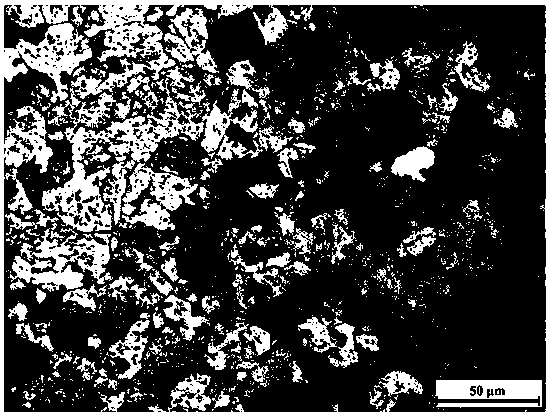

[0011] Example 1: The composition of the etchant used for the display of fine austenite grain boundaries in low-carbon microalloyed steel is 97.5% saturated citric acid solution, saturated FeCl 3 Solution 1%, detergent 1.5%.

[0012] (1) Add 10 mL of deionized water to two beakers, add citric acid to beaker A to saturation, and add FeCl to beaker B 3 to saturation, then use a gel-tip dropper to saturate the FeCl 3 Add the solution dropwise into beaker A, then add detergent and stir evenly; the amount of corrosive agent can be determined according to the sample and beaker capacity, and the corrosive agent is required to soak the sample;

[0013] (2) Put the beaker A into a water bath heating furnace and heat it to 70°C, put the polished steel sample into the beaker A with the polished side up, and keep it warm for 4 minutes. In order to prevent over-corrosion, the corrosion process should be taken every minute Come out to observe the polished surface; after the corrosion is c...

Embodiment 2

[0015] Example 2: The etchant composition used for the display of fine austenite grain boundaries in low-carbon microalloyed steel is saturated citric acid solution: 98%, saturated FeCl 3 Solution 1%, detergent 1%.

[0016] When in use, heat the etchant to 60°C, put the polished steel sample into the etchant, keep the polished surface up, and keep warm for 5 minutes; take out the steel sample and clean it, wipe the polished surface with absolute ethanol, and dry it to obtain Metallographic phase with clear grain boundaries; and the grain boundaries corroded by the etchant are completely displayed, and the corrosion effect is stable.

Embodiment 3

[0017] Example 3: The composition of the etchant used for the display of fine austenite grain boundaries in low-carbon microalloyed steel is 99% saturated citric acid solution, saturated FeCl 3 Solution 0.5%, detergent 0.5%.

[0018] When in use, heat the etchant to 80°C, put the polished steel sample into the etchant, keep the polished surface up, and keep warm for 3 minutes; take out the steel sample and clean it, wipe the polished surface with absolute ethanol, and dry it to obtain Metallographic phase with clear grain boundaries; and the grain boundaries corroded by the etchant are completely displayed, and the corrosion effect is stable.

[0019] The invention is suitable for corroding small austenite grain boundaries of low-carbon microalloy steel, and the corrosion effect of the steel sample with too high carbon content and large grain boundaries is not good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com