A device and method for three-way testing of field soil samples based on shear wave velocity

A testing device, shear wave technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the cumbersome test methods and cannot completely reflect the original soil Anisotropy, Parallel Alignment of Piezoelectric Ceramics with Unbendable Elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

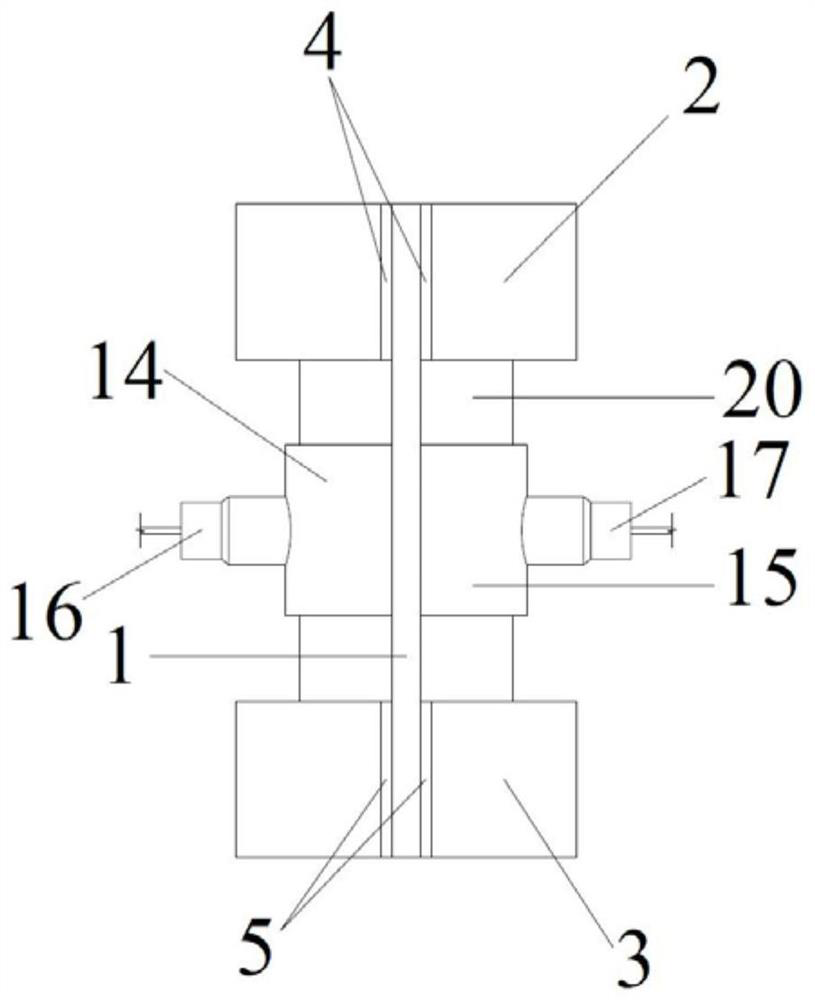

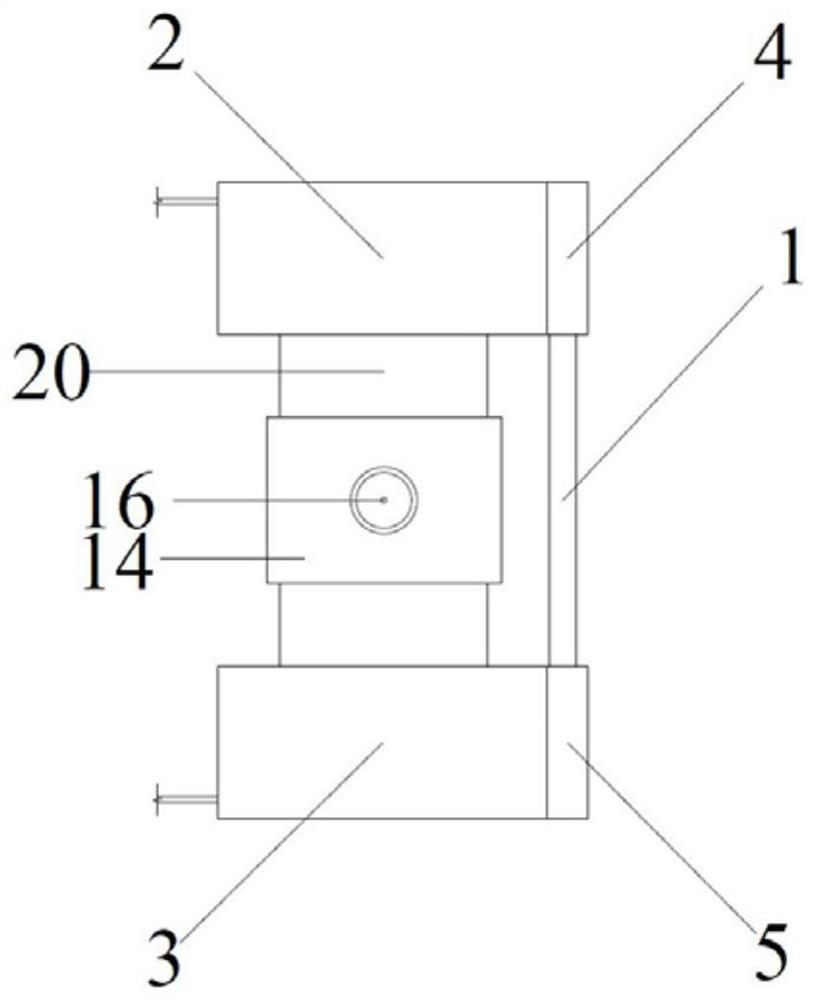

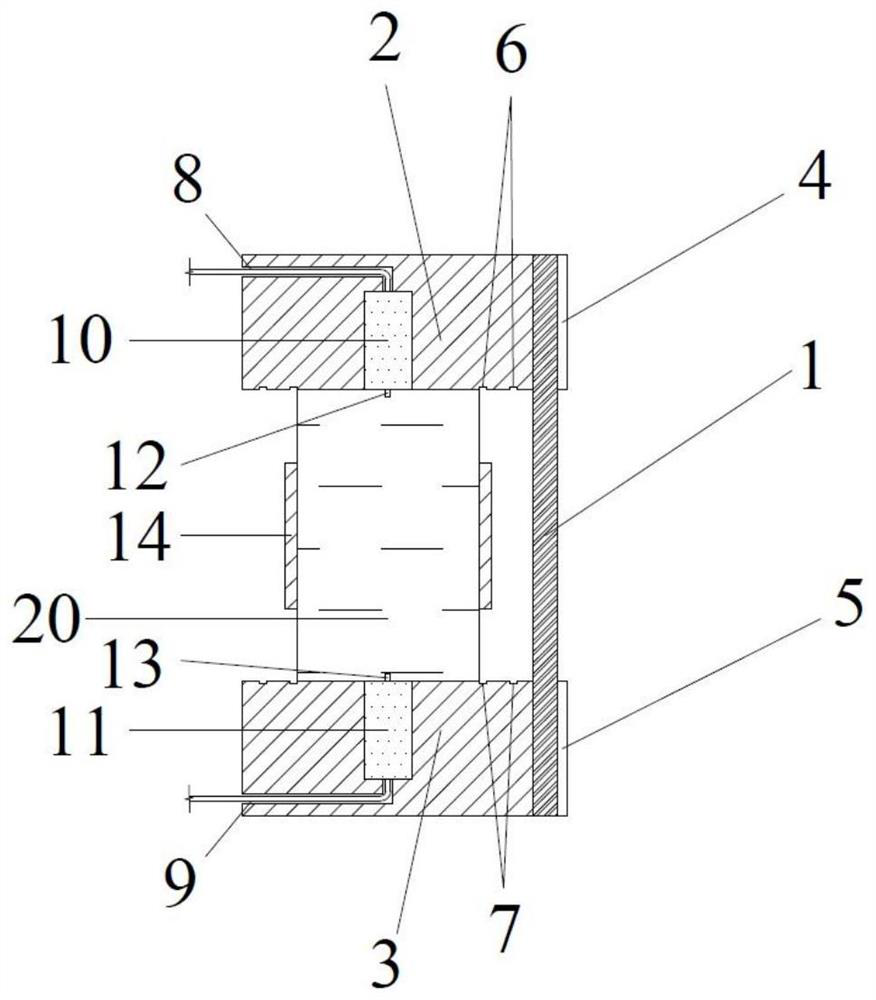

[0047] Such as figure 1 , figure 2 , image 3 As shown, a three-way test device for field soil samples based on shear wave velocity includes a positioning rod 1, a top hat 2 equipped with a bending element, a base 3 equipped with a bending element, and a split Die 14, split die 15 equipped with a bending element. The top cap 2 and the base 3 have the same structure, and their bodies are both cylindrical. The cross-section of the positioning rod 1 is a square with a side length of 10 mm, which is used to ensure that the top cap 2 and the base 3 maintain a correct positional relationship during use of the device. The split molds 14, 15 have the same structure, and their cross-sections are all semicircular.

[0048] The top cap 2 includes a bending element 10 , a positioning groove 4 , a circular groove 6 , and a cable channel 8 . The top hat 2 is made of steel, with a height of 55mm and a diameter of 120mm. A hole with a diameter of 20 mm and a depth of 40 mm is cut at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com