Nano Ag-AgCl solid non-polarized electrode and preparation method thereof

A technology of polarized electrodes and solids, applied in the field of nano-Ag-AgCl solid non-polarized electrodes and their preparation, can solve the problems of inability to guarantee the measurement accuracy, increase the polarization potential, and exceed eight hours, and achieve long-term stable measurement , the ideal polarization potential difference, the effect of reducing the offset of the current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

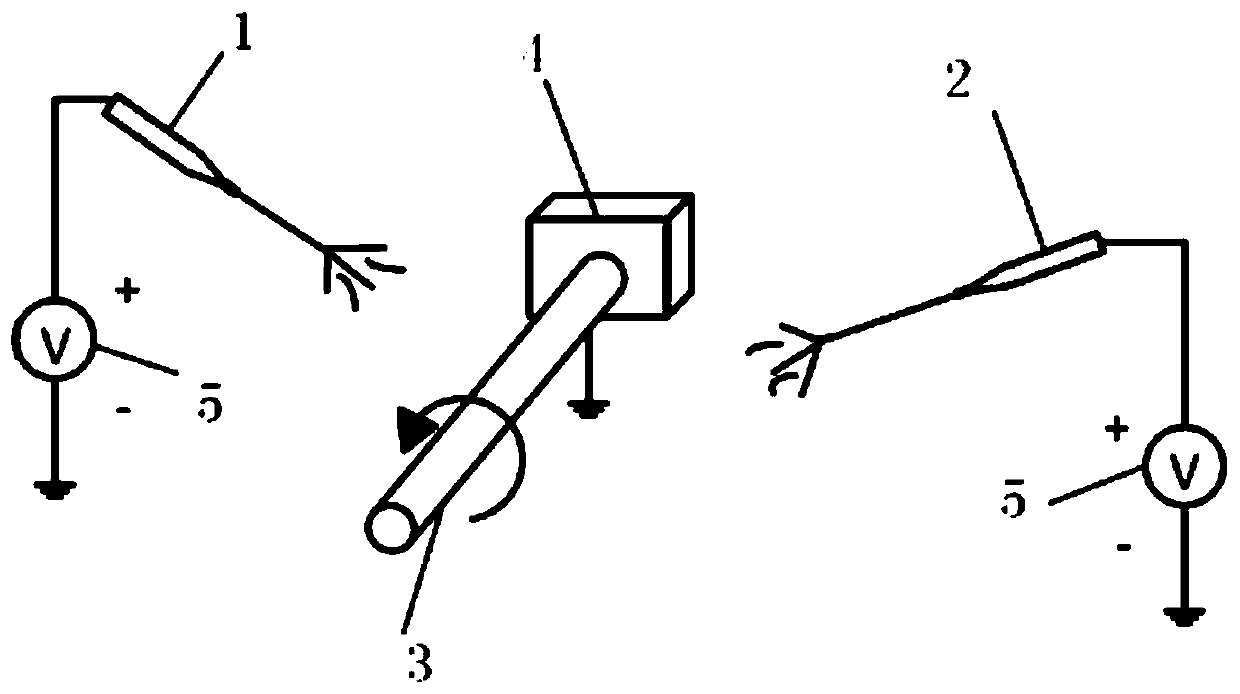

[0044] In order to make the purpose, advantages, and design process of this invention clearer, the embodiments of this invention will be further explained in conjunction with the accompanying drawings.

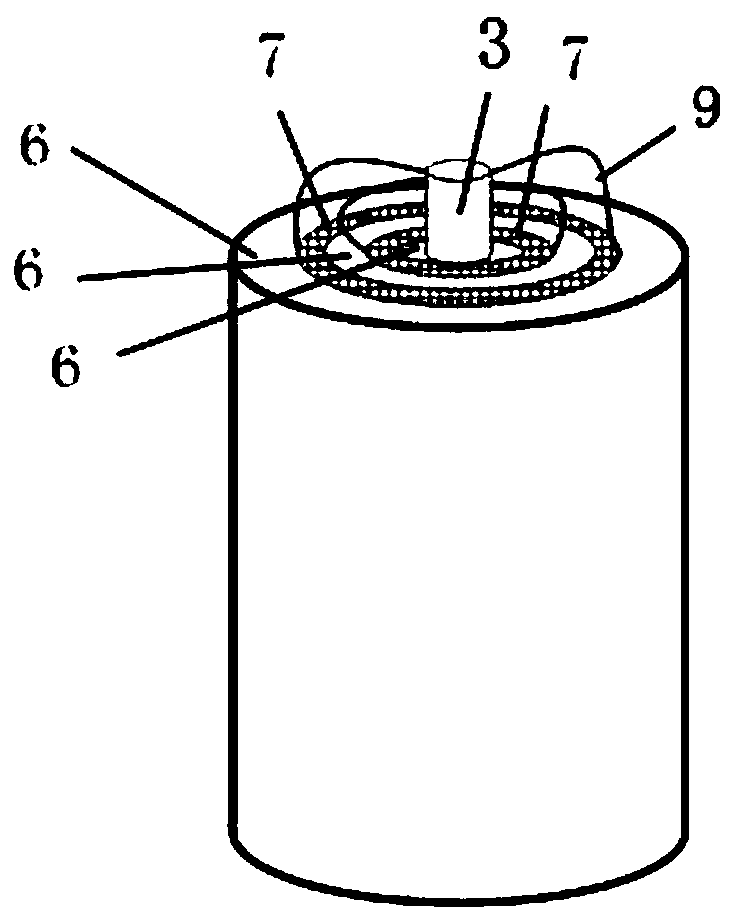

[0045] The Ag / AgCl solid non-polarized electrode of the present invention comprises a non-polarized electrode column, an electrode column top cover 12 is installed on the top of the non-polarized electrode column, and a hydrogel layer 13 is provided on the side and the bottom surface, and the bottom hydrogel layer A permeable ceramic layer 14 is also provided below the 13, and an electrode outer protective shell 10 capable of wrapping the electrode column top cover 12 and the hydrogel layer 13 is also provided above the permeable ceramic layer 14;

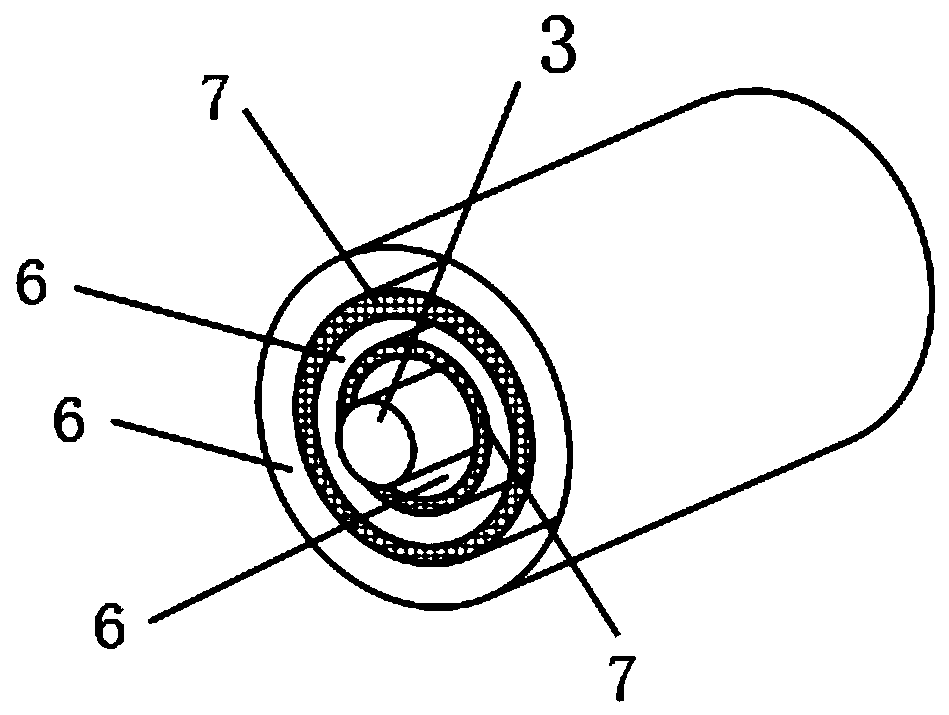

[0046]The non-polarized electrode column includes a silver column 3, a 3-layer Ag and AgCl nano-mixed layer 6 and a 2-layer Ag electrode layer 7, and the 3-layer Ag and AgCl nano-mixed layer 6 and the 2-layer Ag electrode layer are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com