An optical fiber adapter and an optical fiber connection structure

A technology of optical fiber adapter and optical fiber connector, which is applied in the direction of instruments, optics, light guides, etc., can solve problems such as large stress and damage to optical components, and achieve the effects of simple structure, improved yield rate, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

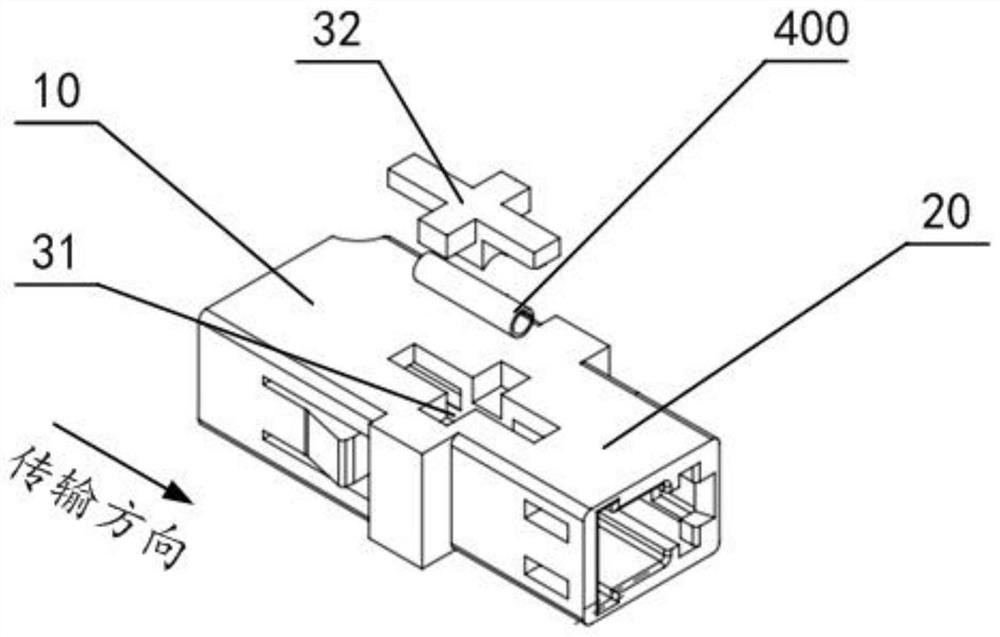

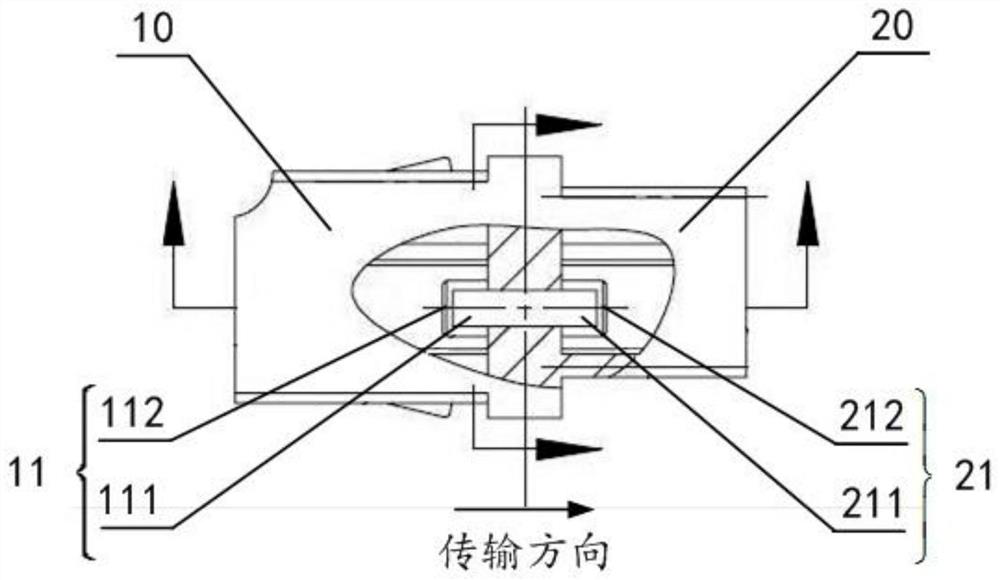

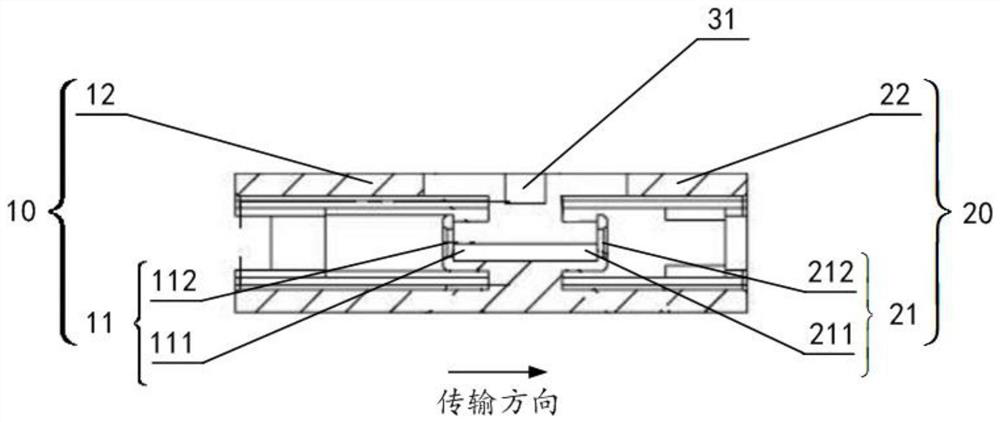

[0054] Such as Figure 1~3 As shown, the first fiber optic adapter provided in this embodiment includes an adapter body and an optical assembly 400, wherein the adapter body includes an adapter input end 10 and an adapter output end 20, and at the adapter input end 10 The input end alignment holder 11 including the input end receiving cavity 111 and the input end stopper 112 is provided at the place, and the output end 20 of the adapter is provided with the output end receiving cavity 211 and the output end stopper 212. The output end alignment holder 21; the contour body of the input end accommodation chamber 111 extends linearly toward the output side direction, and the contour body of the output end accommodation chamber 211 extends linearly toward the input side direction, so that the two contour bodies overlap to form a The integrated contour structure of the optical assembly 400 is accommodated, and an opening structure for loading the optical assembly 400 is provided on...

Embodiment 2

[0064] Such as Figure 4 As shown, on the basis of the technical solution of Embodiment 1, this embodiment provides another optical fiber adapter with a simplified structure, which defaults to the setting of the input port structural support 12 and the output port structural support 22, and only adds A circumferential body structure support 40 ensures the stability of the integral profile structure.

[0065] The technical effect of this embodiment can be directly derived by referring to the technical effect of the first embodiment, and will not be repeated here.

Embodiment 3

[0067] Such as Figure 5-7 As shown, this embodiment provides another fiber optic adapter on the basis of the technical solution of Embodiment 1. The end accommodating cavities 211 are all O-shaped accommodating cavities, and the opening structure is located at the input side end or output side end of the integrated contour structure and includes an end face opening and a stopper at the corresponding end, wherein the stopper The component is the input end stopper 112 or the output end stopper 212; the optical assembly 400 is installed into the integrated contour structure through the end face opening of the corresponding end and in an unobstructed state before setting the stopper , and then set the stopper connection on the socket profile on the corresponding side. Such as Figure 5-7 As shown, for example, before the output stopper 212 of the optical assembly 400 is set, since the end face opening at the output end is in an unobstructed state, it can be conveniently inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com