AGV universal solution platformization kit

A solution, platform-based technology, applied in non-electric variable control, instrumentation, two-dimensional position/channel control, etc., can solve problems such as unfavorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

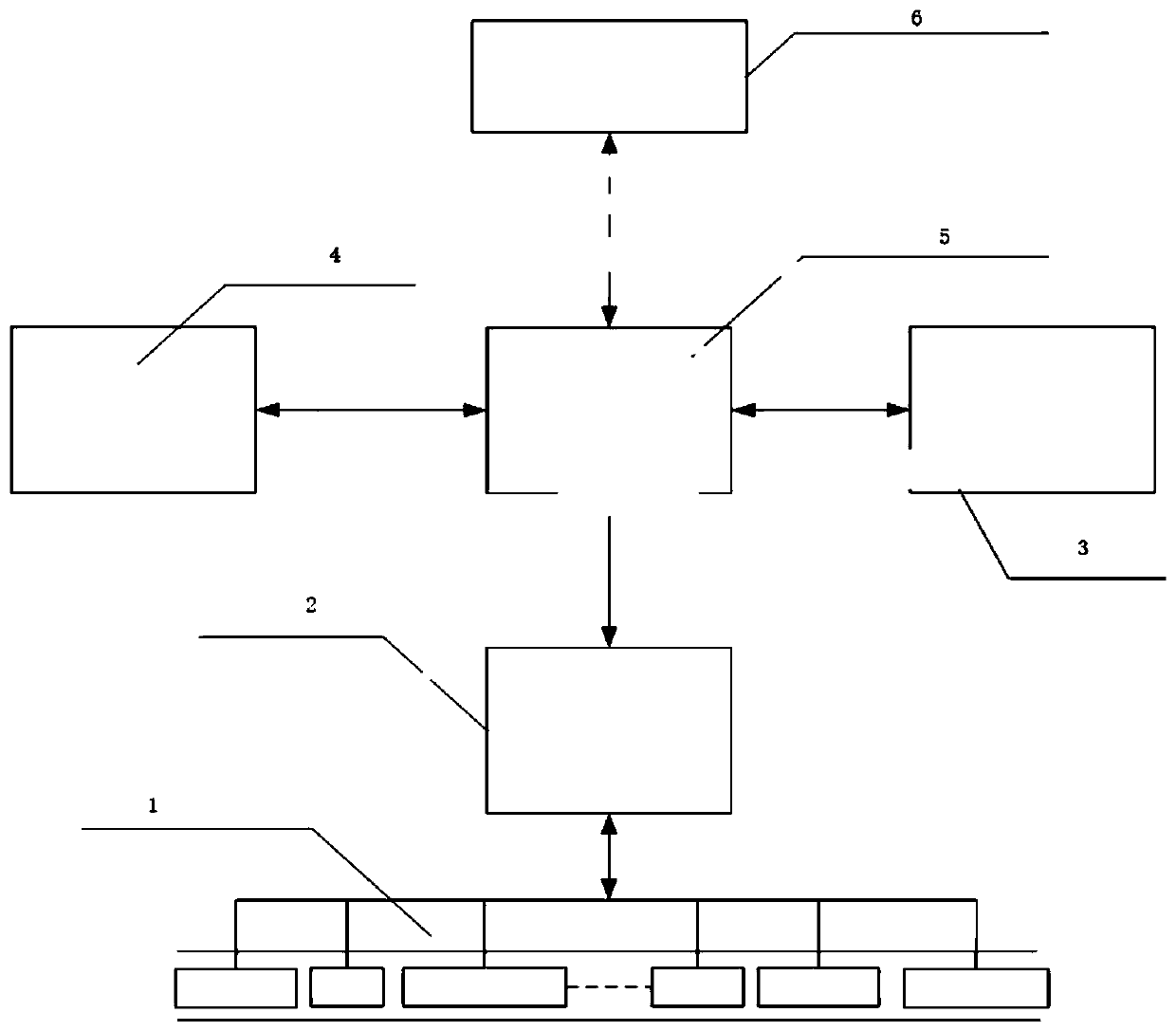

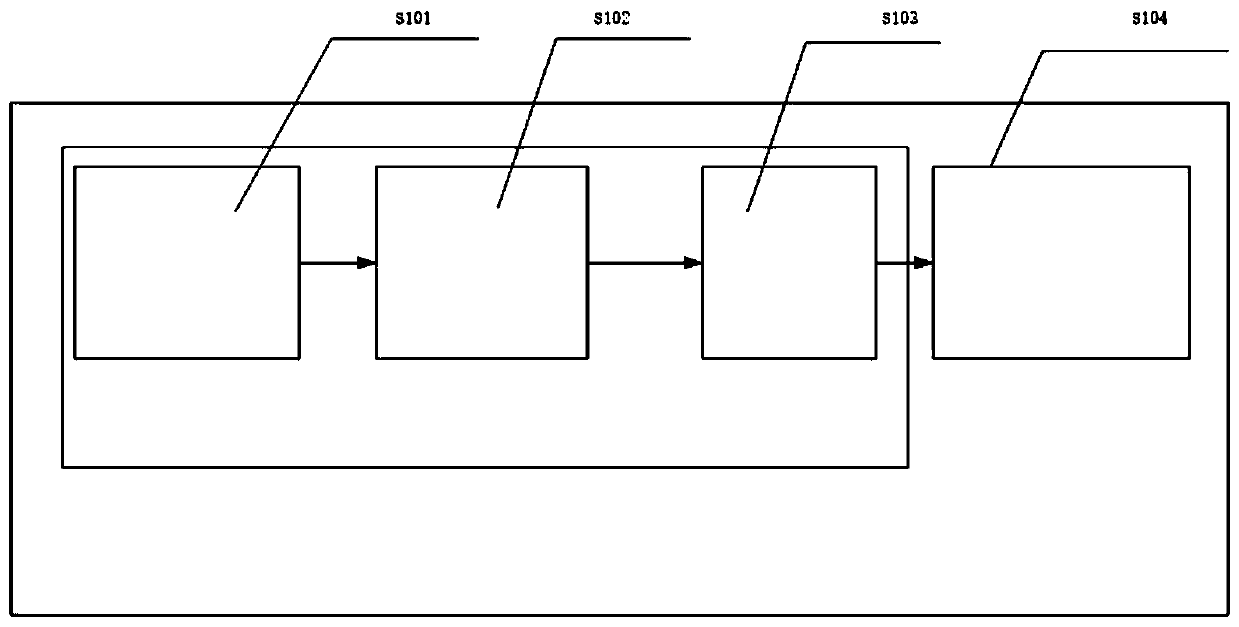

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

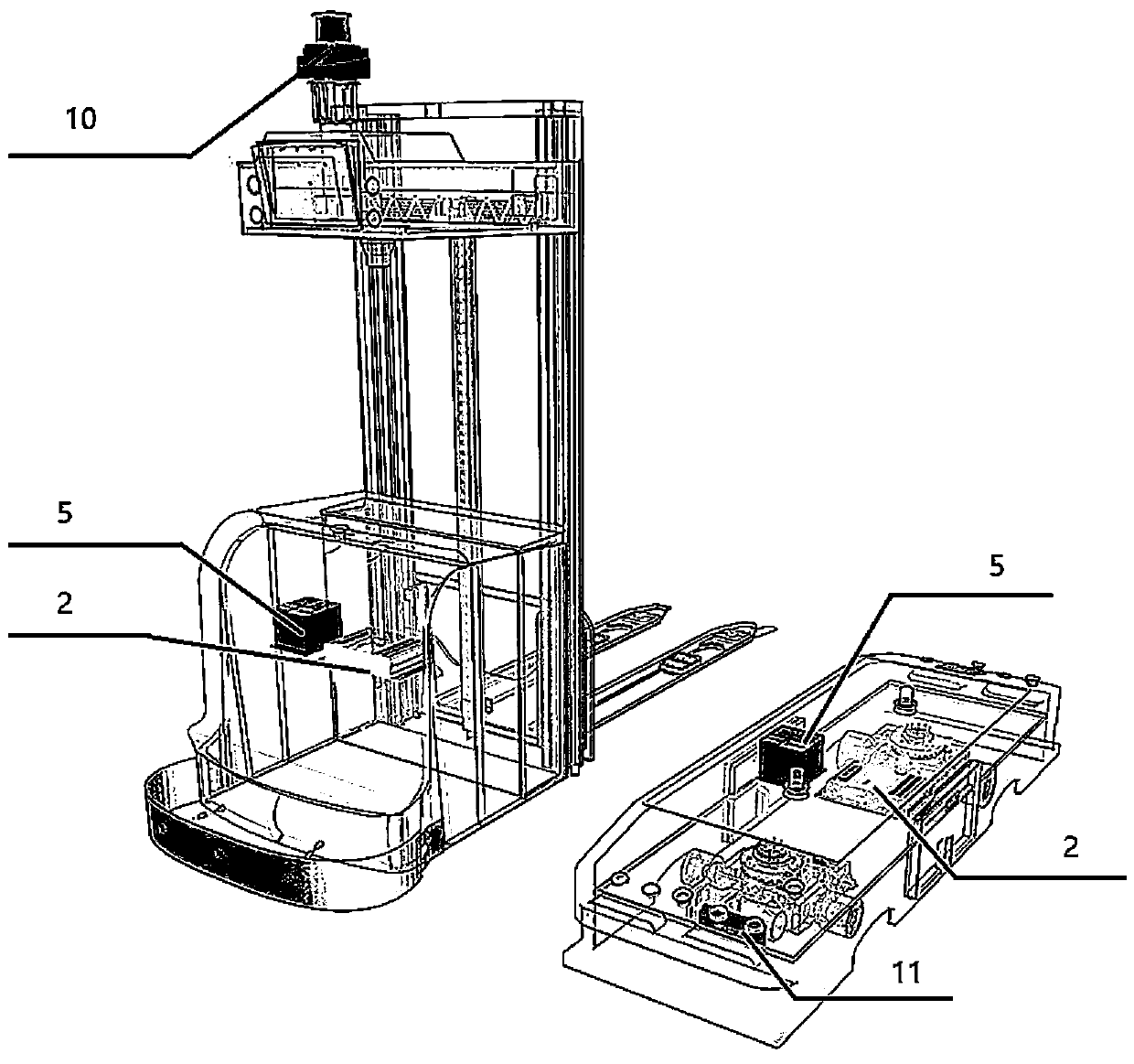

[0047] Such as image 3 As shown, the left AGV is equipped with a laser navigation sensor 10 , and the laser guidance sensor belongs to the AGV peripheral device 1 . Through the judgment of the guidance and navigation device, it can be known as laser navigation AGV.

[0048] In the production stage, the AGV special controller 5 and the integrated electric control box 2 are installed on the AGV car body, and other AGV peripheral devices are distributed on the car body, and the AGV peripheral devices and the AGV special controller 5 are connected through a standardized wiring harness that can be mass-produced To complete the electric control box 2, complete the production of AGV. In the production stage, the use of standardized wiring harness connections can avoid manual wiring errors and enhance the reliability of AGV products.

[0049] In the debugging stage, after the AGV is powered on, it can be connected to the AGV dedicated controller 5 through the stand-alone monitoring...

Embodiment 2

[0052] Such as image 3 As shown, the AGV on the right is equipped with a tape guide sensor 11, and the tape guide sensors belong to the AGV peripheral device 1. Through the judgment of the guidance and navigation device, the AGV is guided by the tape.

[0053] In the production stage, the AGV special controller 5 and the integrated electric control box 2 are installed on the AGV car body, and other AGV peripheral devices are distributed on the car body, and the AGV peripheral devices and the AGV special controller 5 are connected through a standardized wiring harness that can be mass-produced To complete the electric control box 2, complete the production of AGV. In the production stage, the use of standardized wiring harness connections can avoid manual wiring errors and enhance the reliability of AGV products.

[0054] In the debugging stage, after the AGV is powered on, it can be connected to the AGV dedicated controller 5 through the stand-alone monitoring tool 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com