Battery pack management system and battery pack management method

A technology for battery pack management and single cells, applied in battery/fuel cell control devices, secondary batteries, secondary battery repair/maintenance, etc., can solve problems affecting the normal operation of the battery pack and the failure of the battery pack to work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

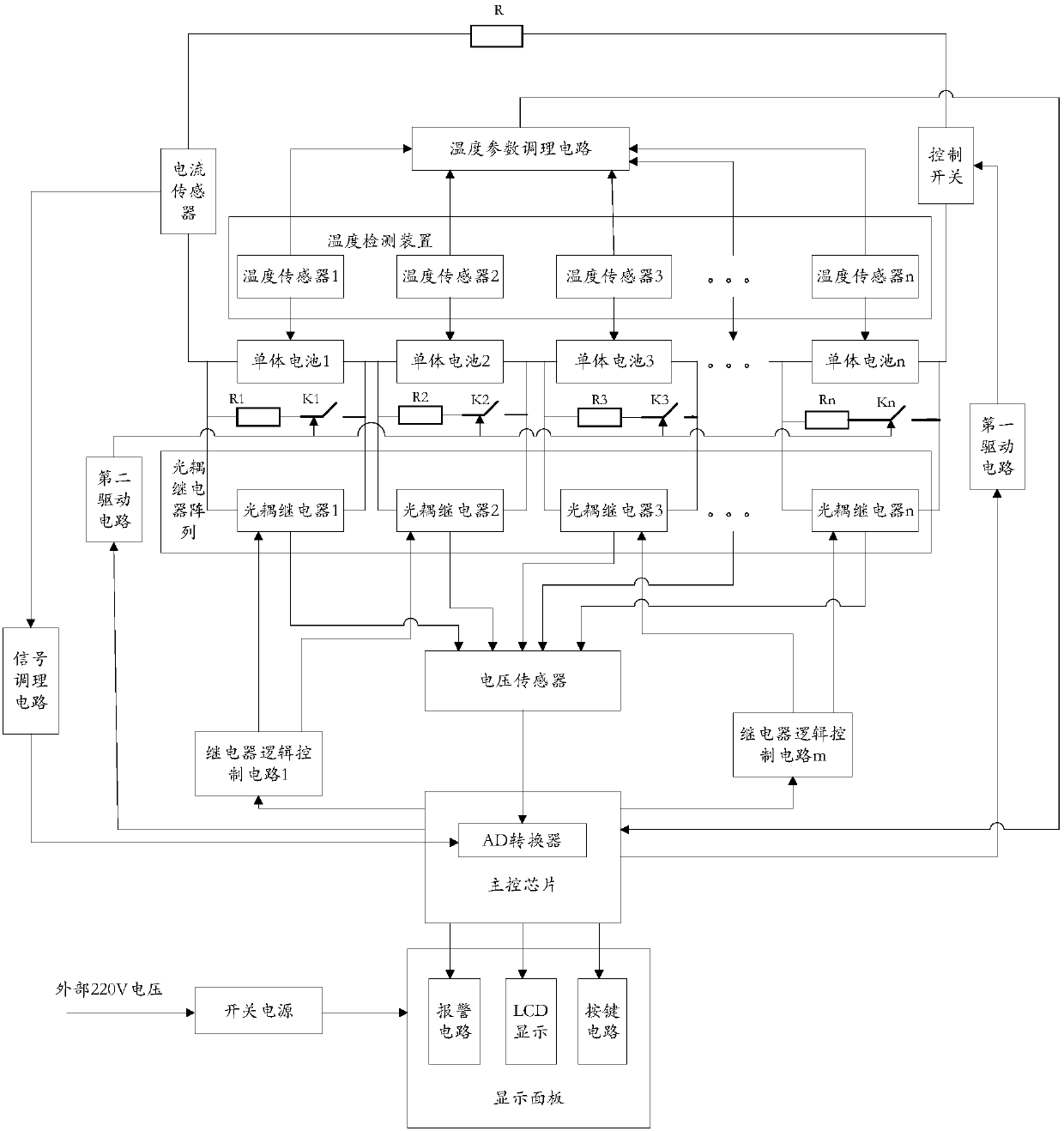

[0047] Embodiment 1. A battery pack management system. Combine below figure 1 The system provided in this embodiment will be described.

[0048] see figure 1, the battery pack management system provided in this embodiment includes a battery pack composed of n single cells in series and a main circuit composed of a resistive load R, and also includes a temperature detection device, a temperature parameter conditioning circuit, an optocoupler relay array, a voltage sensor, A current sensor, a main control chip, at least one relay logic control circuit, a drive circuit, a control switch and a display panel. The temperature detection device includes n temperature sensors, and each temperature sensor is arranged on a corresponding single battery for detecting the working temperature of the corresponding single battery; each temperature sensor is connected with a temperature parameter conditioning circuit, and is used to It is used to send the detected operating temperature of th...

Embodiment 2

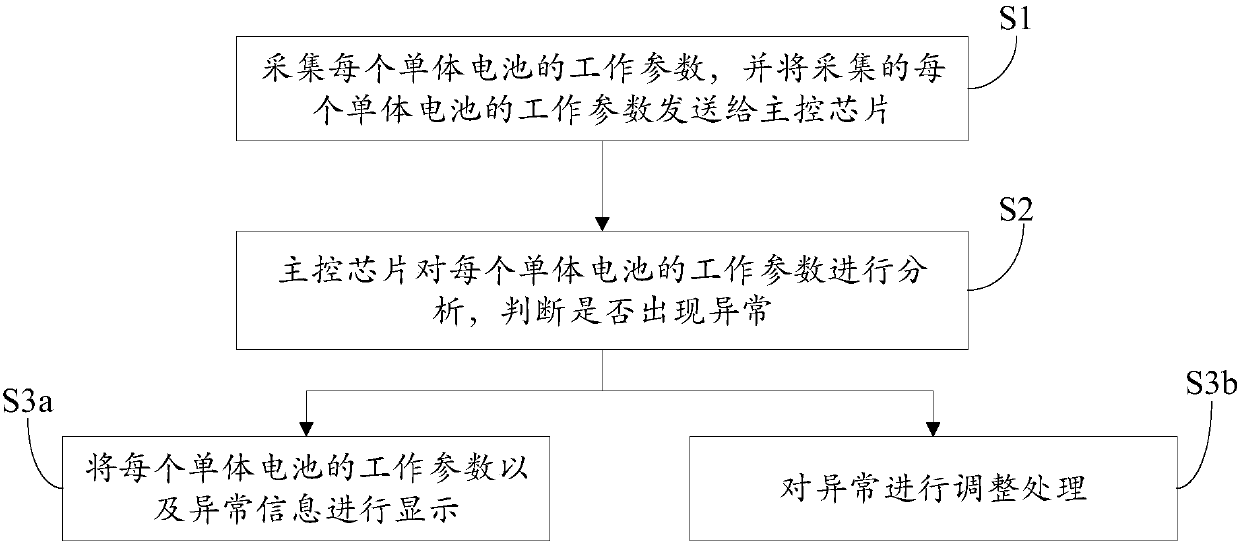

[0054] Embodiment 2, a battery pack management method. Combine below figure 2 The method provided in this embodiment is described.

[0055] see figure 2 , the method provided in this embodiment includes: S1. A temperature sensor arranged on each single battery detects the operating temperature of each single battery, and an optocoupler relay connected in parallel with each single battery detects the operating voltage of each single battery, and connects them in series The current sensor in the main circuit detects the working current of each single battery, and sends the working temperature, working voltage and working current of each single battery to the main control chip.

[0056] Specifically, each temperature sensor is connected to the temperature parameter conditioning circuit, and each temperature sensor sends the detected working temperature of the corresponding single battery to the main control chip through the temperature parameter conditioning circuit; each opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com