Mining self-power-generation type inspection robot system and control method

An inspection robot and self-generating technology, applied in the field of robotics, can solve problems such as battery pack battery working time limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

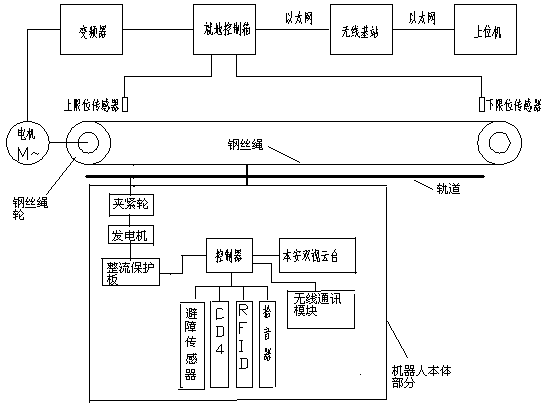

[0021] Such as figure 1 As shown, a self-generating inspection robot system for mining is composed of two parts: the drive control part and the robot body.

[0022] The drive control part includes: upper computer, wireless base station, local control box, frequency converter, motor, wire rope, wire rope pulley, track, upper limit sensor and lower limit sensor. The upper computer communicates with the wireless base station through Ethernet connection; the wireless base station communicates with the local control box through Ethernet connection; the local control box is connected with a frequency converter, and the frequency converter drives the motor to rotate. A wire rope wheel is respectively installed at the starting point and the end point of the inspection robot inspection line, and the wire rope is wound on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com