Fuel assembly simulation device with adjustable fuel rod clamping force

A fuel assembly and simulation device technology, applied in climate sustainability, nuclear reactor monitoring, reactors, etc., can solve problems such as inability to meet the needs of assembly repair tests and training, screw jamming, and easy damage to guide tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

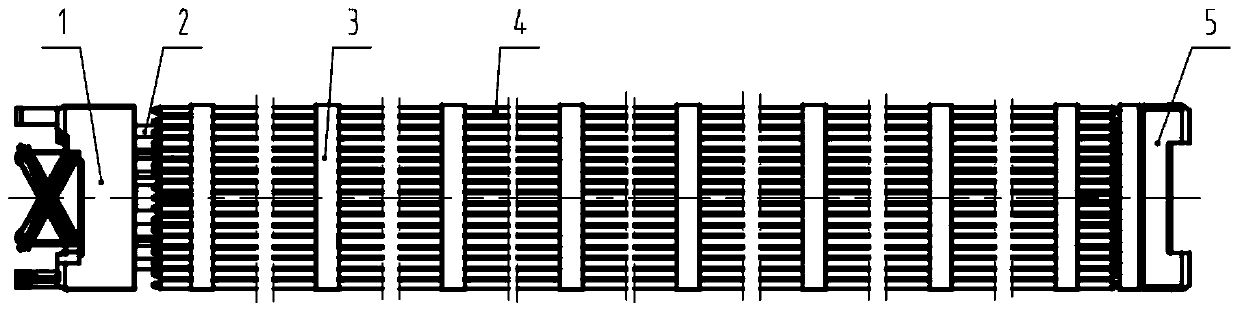

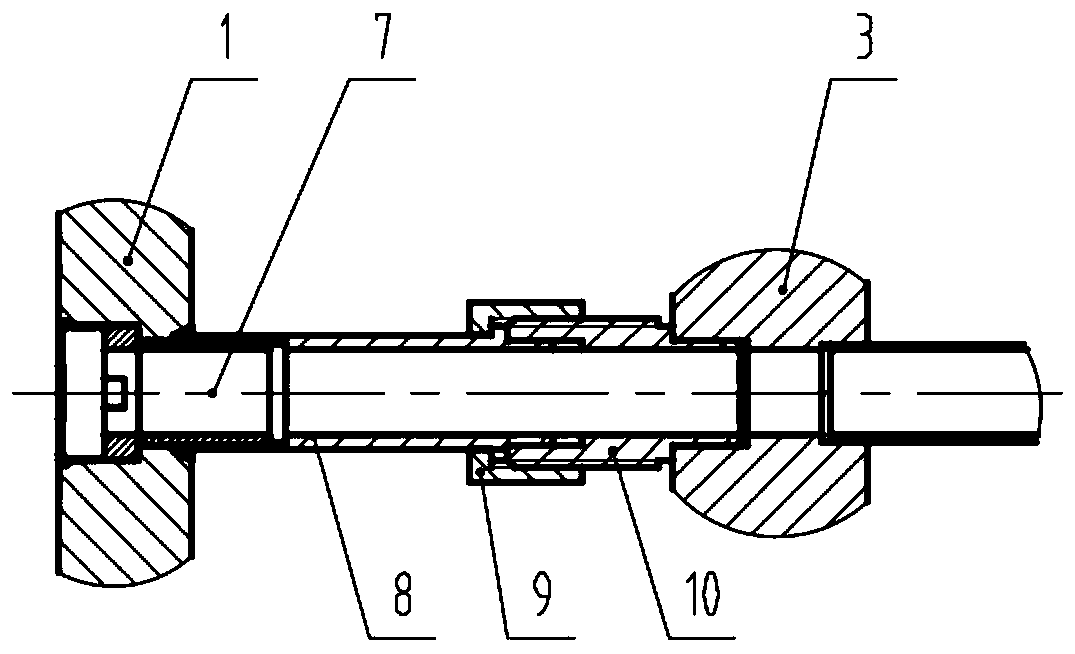

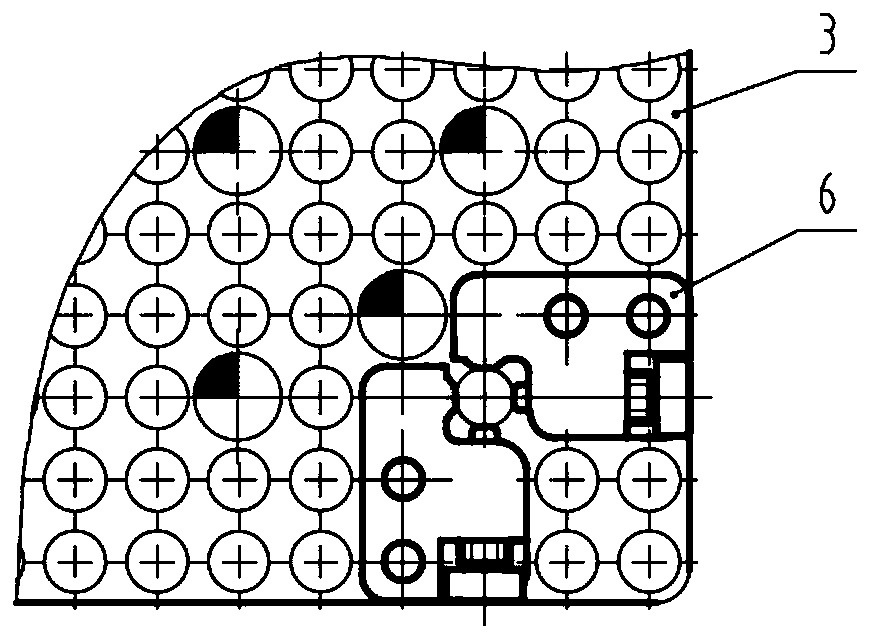

[0020] Such as figure 1 As shown, a fuel assembly simulation device with adjustable fuel rod clamping force includes an upper tube base 1, a guide tube 2, a grid 3, a fuel rod 4, a lower tube base 5 and a clamping force adjustment mechanism 6, wherein, Between the lower tube base 5 and the upper tube base 1, several guide pipes 2 are arranged, and several grid frames 3 are parallel to each other and fixed between the upper tube base 1 and the lower tube base 5. Regularly arranged holes, a number of fuel rods 4 are supported and fixed on the grid 3 and parallel to the guide tube 2. Among them, the fuel assembly formed by the upper tube base 1, the grid frame 3, the fuel rods, and the lower tube base 5 simulates The overall dimensions and main structural connections of the device are consistent with those of the real fuel assembly; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com