Flexible anti-nuclear reinforced cable and manufacturing method

A production method and cable technology, which are applied in the direction of cable/conductor manufacturing, insulated cables, and bendable cables, etc., which can solve the problem of broken and detached cable conductors, uneven stress on cable bending parts, and poor flexibility of anti-nuclear electromagnetic pulse cables. and other problems, to achieve the effect of improving reliability, solving poor softness, and solving softness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

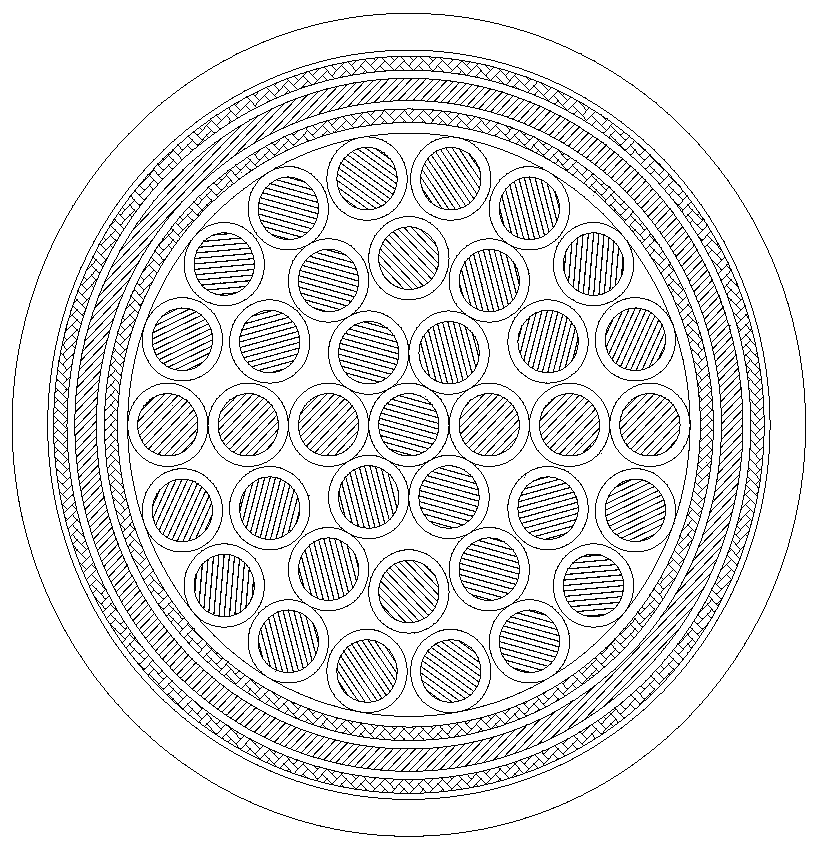

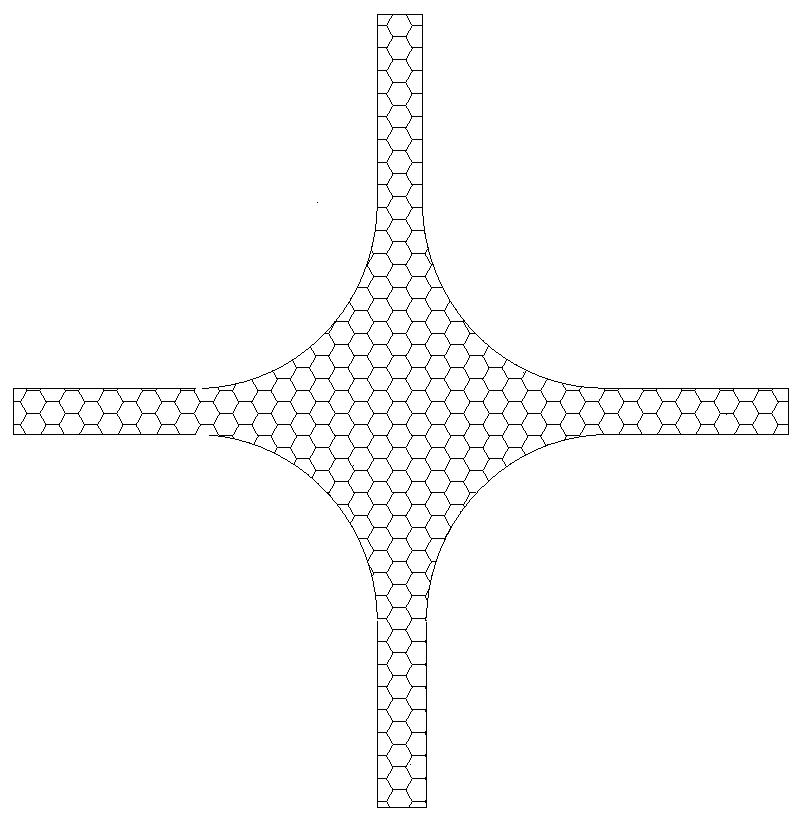

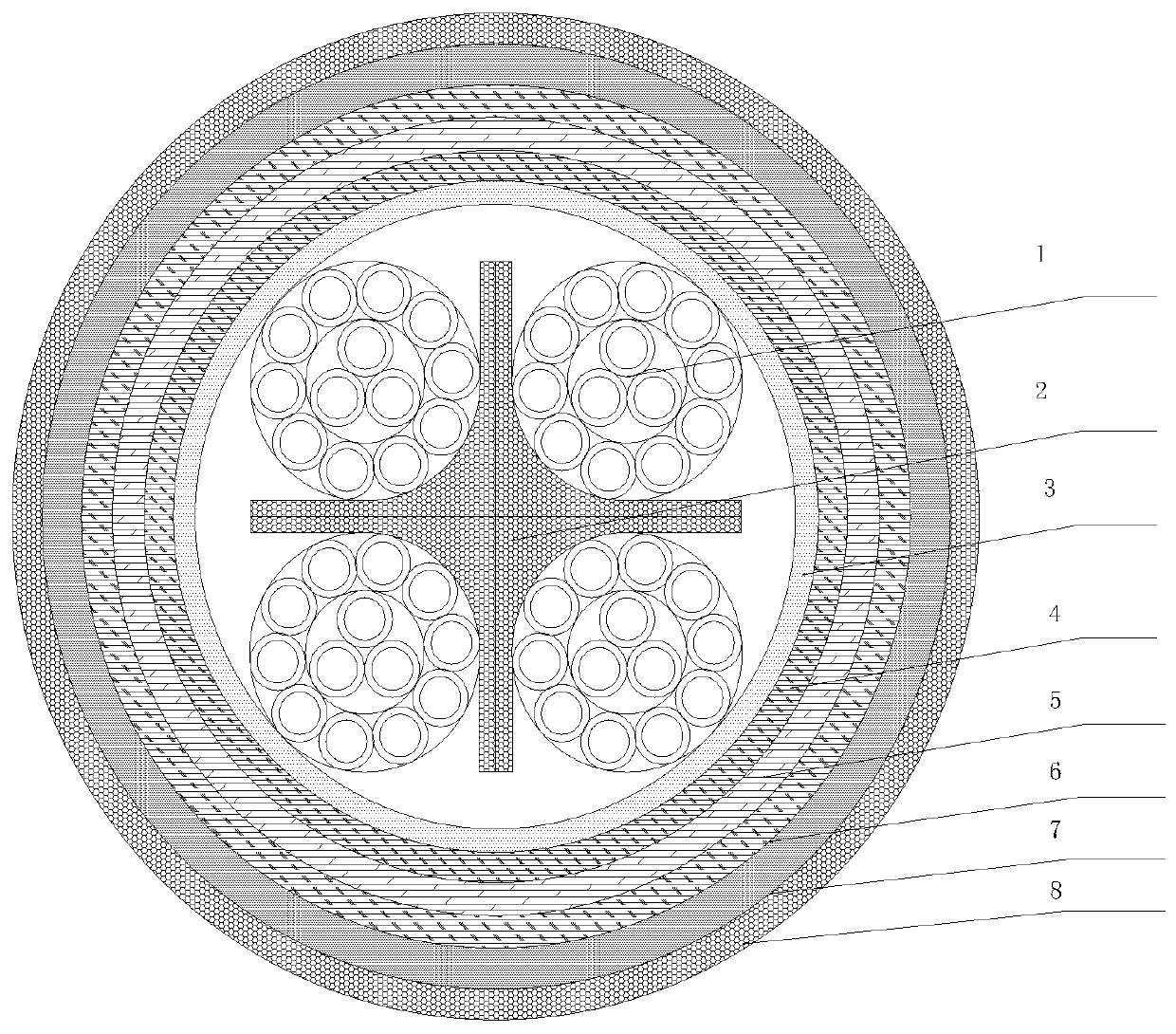

[0038] Such as image 3 , a flexible anti-nuclear reinforced cable, including a central frame 2, a cable core unit 1, a polyester wrapping layer 3, a shielding layer, and a polyurethane sheath layer 8 from the inside to the outside, the central frame 2 is made of TPEE material and the cable core unit 1 are respectively isolated in the wrapping space of the wrapping layer 3 . The number of cable core units 1 is four, and the cross-section of the central frame 2 is cross-shaped. The cable core units 1 are respectively placed on the four corners of the central frame 2 to be isolated, and the wrapping layer 3 is made of a transparent polyester tape material with a thickness of 0.03mm. , the shielding layer from the inside to the outside is the first silver-plated copper braid layer 4, the copper-nickel alloy cloth tape wrapping layer 5, the nickel-iron alloy tape wrapping layer 6, and the second silver-plated copper braid layer 7. Multi-layer shielding is used to shield the elect...

Embodiment 2

[0061] On the basis of Example 1, the central frame 2 is replaced with TPU material, the number of cable core units 1 is eight and the cross-section of the central frame 2 is a rice-shaped structure, and the cable core units 1 are independently separated by rice sub-frames. Its preparation steps also carried out parameter adjustment on the basis of embodiment 1:

[0062] Step 1: Make the cable core unit, twist the prepared thirteen-core insulated core wires and the twisted structure is 3 cores inside and 10 cores outside, and wrap a layer of polyester film tape on the outer layer synchronously after twisting A cable core unit is manufactured, and the outer diameter of the obtained cable core unit is about 4.2 mm.

[0063] Step 2: Assemble the cable, install the cable core unit cable tray symmetrically on the cable forming machine, install the central frame cable tray at the center of the cable forming machine, and then distribute the cable core units at each corner of the cent...

Embodiment 3

[0071] On the basis of Example 1, the central frame 2 was replaced by rubber material. After bending 3000 times through experiments, the performance of the cable did not change significantly in all aspects, which met the requirements for the use of the cable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com